Strategic Developments and Innovations Shaping Indonesia Additive Manufacturing Market

Introduction:

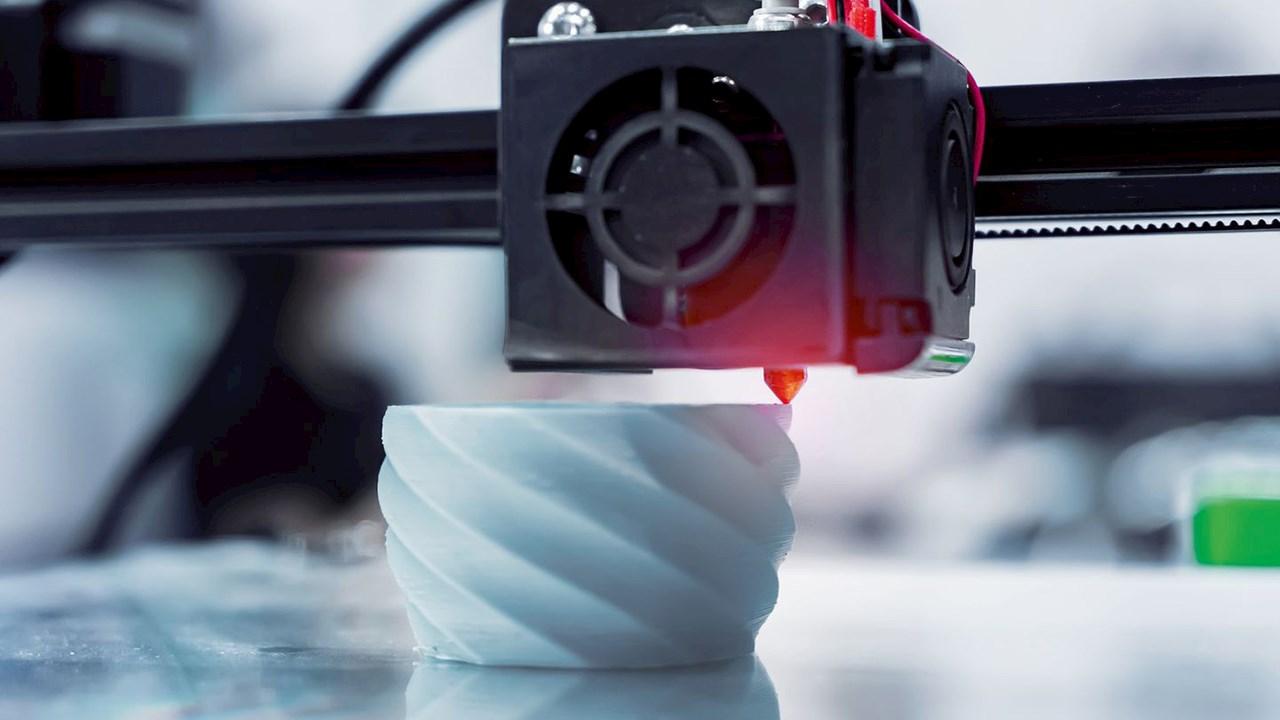

The Indonesia Additive Manufacturing Market has experienced significant growth, this expansion is driven by the adoption of advanced technologies, strategic initiatives, and the integration of innovative solutions across various industries. As Indonesia strengthens its position in the global manufacturing arena, additive manufacturing is becoming a pivotal factor in transforming traditional production systems and fostering innovation.

Strategic Initiatives and Government Support

This strategy focuses on enhancing the manufacturing sector through the adoption of Industry 4.0 technologies, including additive manufacturing. By embracing digitalization and automation, the initiative seeks to boost productivity, foster innovation, and attract foreign investment, thereby creating a conducive environment for the growth of the AM market.

In addition to this, government policies are promoting the integration of advanced manufacturing technologies, such as 3D printing, robotics, and AI, into industries ranging from aerospace to healthcare. These efforts are expected to enhance Indonesia’s global competitiveness, attract more investment, and provide opportunities for local businesses to innovate and expand their capabilities.

Integration of Artificial Intelligence and Advanced Technologies

The integration of artificial intelligence (AI) into additive manufacturing is a significant trend in Indonesia. AI helps optimize production processes, improve product design capabilities, and facilitate the creation of intricate and customized objects. In the AM market, AI assists in predictive maintenance, real-time monitoring, and performance analysis, allowing manufacturers to anticipate potential issues and reduce downtime.

Moreover, AI-driven design tools are enabling the creation of more efficient and precise components by enhancing the design-to-manufacturing workflow. The combination of AI with 3D printing technology not only speeds up production cycles but also ensures that products meet higher standards of quality and functionality. This integration is expected to broaden the applications of 3D printing, offering more efficient and cost-effective solutions across various sectors, from automotive to medical devices.

Emerging Innovations and Developments

The Indonesian AM market is embracing several innovations that are driving its expansion and revolutionizing industries. Some key trends include:

· Advanced Materials: The development and use of new materials, such as high-performance polymers and metal alloys, are expanding the capabilities of 3D printing. These materials enable the production of durable and functional components that can withstand extreme conditions. For instance, lightweight and heat-resistant materials are crucial for industries like aerospace and automotive. As manufacturers seek to improve the strength and performance of 3D-printed parts, the demand for advanced materials is expected to increase significantly.

· Digital Twins and Nanotechnology: The adoption of digital twins (virtual replicas of physical systems) and nanotechnology is enhancing the precision and efficiency of manufacturing processes. Digital twins allow for real-time monitoring of production, enabling manufacturers to optimize operations and predict potential failures before they occur. Nanotechnology, on the other hand, is enabling the creation of extremely detailed and high-performance structures, which is beneficial for industries like healthcare, where precision is critical. These technologies are empowering Indonesian manufacturers to produce more complex and efficient components.

· Electrochemical Methods: Innovations in electrochemical methods are contributing to more sustainable and efficient manufacturing processes. Electrochemical techniques, such as electroplating and electroforming, can reduce waste and energy consumption in the AM process. These methods are gaining traction due to their ability to create high-quality parts with minimal environmental impact. As sustainability becomes a key focus for industries globally, Indonesia’s adoption of such methods can lead to a more eco-friendly manufacturing environment.

Market Growth and Projections

This robust growth is attributed to the increasing adoption of AM technologies across various industries, including aerospace, automotive, healthcare, and consumer goods. The ability to produce customized parts, reduce waste, and enhance production efficiency is attracting businesses to adopt 3D printing as a core part of their manufacturing processes.

As industries like automotive and healthcare continue to grow in Indonesia, additive manufacturing offers a competitive edge by enabling faster prototyping, reduced production costs, and the creation of complex geometries that are difficult to achieve through traditional methods. The market’s expansion is also supported by the government’s strategic initiatives and the integration of advanced technologies, which create a favorable environment for growth.

Challenges and Opportunities

Despite the positive outlook, the Indonesian AM market faces challenges such as high upfront investment costs and the need for skilled workforce development. Advanced 3D printers and specialized materials can be costly, making it difficult for smaller manufacturers to adopt these technologies. However, as the technology matures and more local service providers enter the market, the cost of 3D printing is expected to decrease, making it more accessible to a wider range of businesses.

Another challenge is the need for skilled labor in additive manufacturing. As demand for AM technologies grows, there is a significant need for professionals trained in 3D printing design, machine operation, and material science. Indonesia’s education and vocational training sectors are beginning to address this need by offering specialized programs in additive manufacturing. Businesses can also collaborate with universities and research institutions to foster innovation and develop a skilled workforce.

Addressing these challenges presents opportunities for businesses to invest in training programs, develop cost-effective solutions, and collaborate with government agencies to create a more favorable environment for the adoption of additive manufacturing technologies. By embracing innovation, Indonesian manufacturers can become more competitive on the global stage and position themselves as leaders in the AM industry.

Conclusion

The Indonesian additive manufacturing market is poised for substantial growth, driven by strategic government initiatives, the integration of advanced technologies, and a focus on innovation. Additive manufacturing offers tremendous potential for industries in Indonesia, from automotive to healthcare, enabling manufacturers to reduce costs, improve design capabilities, and produce complex parts more efficiently.

As the market continues to evolve, Indonesia’s growing focus on Industry 4.0 and the integration of AI, advanced materials, and sustainable manufacturing processes will further accelerate the adoption of additive manufacturing. The government’s support for innovation and technological advancement, along with the increasing demand for customized and high-performance parts, will position Indonesia as a key player in the global additive manufacturing landscape.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology