Smartphone Linked Pet Devices Manufacturing Plant Project Report | Process, Setup, and Market Trends

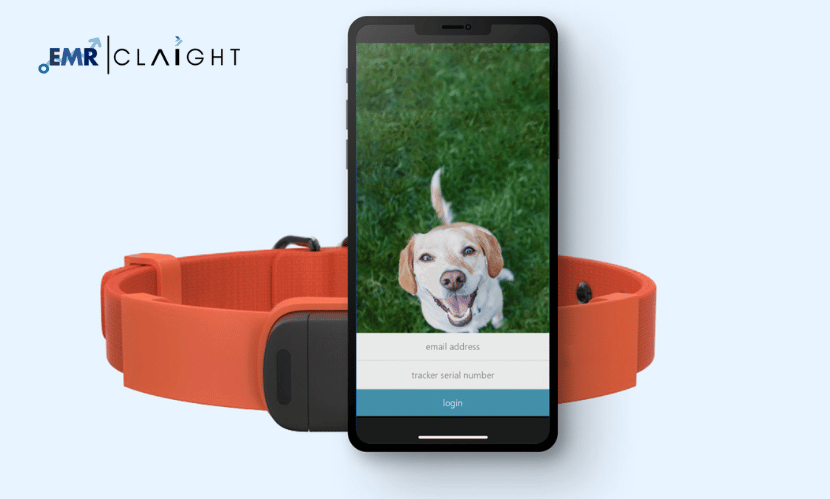

Smartphone-linked pet devices are revolutionising pet care, offering advanced tools to monitor and enhance the well-being of pets. These devices, which include smart collars, feeders, trackers, and health monitors, integrate with mobile apps to provide real-time updates and insights. Designed for tech-savvy pet owners, these products improve safety, health tracking, and convenience. With the growing trend of pet humanisation and increased spending on pet care, the demand for smartphone-linked pet devices is rapidly expanding, presenting a lucrative opportunity for setting up a manufacturing plant in this innovative sector.

Overview of the Manufacturing Process

The production of smartphone-linked pet devices involves precision engineering, advanced technology integration, and rigorous quality control to ensure reliable performance.

Key stages in the manufacturing process include:

- Design and Prototyping: Creating device prototypes using CAD software, focusing on functionality, comfort, and durability.

- Component Sourcing: Procuring high-quality electronic components, sensors, batteries, and durable casing materials.

- Hardware Assembly: Assembling microchips, sensors, and other electronic components into the device structure.

- Software Integration: Installing and testing the device’s software to ensure seamless connectivity with smartphone apps.

- Quality Testing: Conducting performance tests, including durability, water resistance, and signal reliability.

- Packaging: Securely packing the devices in eco-friendly materials, complete with instructions and branding.

- Labelling and Branding: Labelling products with specifications, user guides, and QR codes for app downloads.

Automation in hardware assembly and quality testing enhances efficiency and ensures product consistency.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/smartphone-linked-pet-devices-manufacturing-plant-project-report/requestsample

Plant Setup and Infrastructure

Setting up a manufacturing plant for smartphone-linked pet devices requires advanced technology, skilled labour, and compliance with safety and environmental standards.

Key infrastructure requirements include:

- Design and Prototyping Labs: Facilities for creating and testing prototypes.

- Assembly Lines: Automated or semi-automated lines for assembling electronic components.

- Software Development Units: Workspaces for programming and integrating device software.

- Quality Testing Labs: Equipped with tools for testing device durability, accuracy, and connectivity.

- Packaging Units: Systems for efficient product packaging and labelling.

- Storage Facilities: Climate-controlled areas for storing raw materials and finished products.

Applications and Market Demand

Smartphone-linked pet devices cater to a broad range of pet care needs, driving strong demand across various segments.

Key applications include:

-

Pet Safety:

Smart collars and GPS trackers ensure the safety of pets by providing real-time location tracking. -

Health Monitoring:

Devices equipped with sensors track vital parameters like heart rate, activity levels, and sleep patterns. -

Feeding Automation:

Smart feeders allow pet owners to schedule and monitor feeding times remotely. -

Training Assistance:

Devices with integrated training features help in behaviour correction and obedience training. -

Entertainment:

Interactive toys and devices provide mental stimulation for pets, reducing boredom. -

Emergency Alerts:

Devices send alerts to owners in case of unusual activity or potential health issues.

Regulatory and Environmental Considerations

The production of smartphone-linked pet devices involves adherence to safety regulations and sustainable practices to ensure product quality and minimal environmental impact.

Key considerations include:

- Regulatory Compliance: Ensuring the devices meet safety standards for electronic products and wireless communication.

- Eco-Friendly Materials: Using recyclable and non-toxic materials for device casings and packaging.

- Data Privacy: Complying with data protection regulations to safeguard user information collected via apps.

- Worker Safety: Providing training and safety measures for employees handling electronic components.

- Waste Management: Implementing systems for recycling e-waste and minimising production by-products.

Cost Factors and Investment

Setting up a smartphone-linked pet device manufacturing plant involves costs related to infrastructure, raw materials, equipment, and operational expenses. Investments in research and development, certifications, and marketing are essential for remaining competitive in this growing market.

Conducting a feasibility study helps assess market potential, resource allocation, and operational challenges. Collaborating with software developers and electronics suppliers can streamline production and improve efficiency.

Features of a Modern Manufacturing Facility

Modern facilities for smartphone-linked pet device production integrate advanced technologies and sustainable practices to ensure efficiency and quality.

Key features include:

- Automation: Enhances production speed and ensures consistent quality.

- Energy Efficiency: Utilises energy-saving equipment to reduce operational costs and environmental footprint.

- Real-Time Monitoring: Tracks production parameters to optimise efficiency and detect issues early.

- Sustainability Practices: Focuses on eco-friendly materials and waste reduction.

- Scalability: Designed to accommodate future expansions and meet increasing market demand.

Challenges and Opportunities

The smartphone-linked pet device market offers significant growth potential but also presents certain challenges:

- Market Competition: Competing with established brands requires innovative features and strong branding.

- Raw Material Costs: Fluctuations in the prices of electronic components and batteries can impact production costs.

- Consumer Awareness: Educating pet owners about the benefits of these devices can boost adoption rates.

Opportunities include targeting emerging markets, developing affordable models for budget-conscious consumers, and offering customisation options for specific pet types. Leveraging digital marketing and e-commerce platforms can further expand reach and sales.

Operational Best Practices

Efficient operations are critical for the success of a smartphone-linked pet device manufacturing plant. Recommended practices include:

- Routine Maintenance: Keeps machinery in optimal condition and minimises downtime.

- Employee Training: Equips workers with skills to handle advanced equipment and maintain safety standards.

- Quality Assurance: Implements stringent testing to ensure product reliability and compliance with safety standards.

- Inventory Management: Balances raw material procurement with finished product demand effectively.

Future Prospects

The demand for smartphone-linked pet devices is expected to grow as pet owners increasingly adopt technology-driven solutions for pet care. Manufacturers focusing on innovation, quality, and sustainability will be well-positioned to capture this growth and establish a strong presence in the global market.

Establishing a smartphone-linked pet devices manufacturing plant presents a lucrative opportunity to meet the rising demand for smart pet care solutions while contributing to the advancement of the pet technology industry.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology