Acetylene Price Trend Analysis and Market Reports

Acetylene (C₂H₂) is a colorless, highly flammable gas with a distinct odor, and it plays a crucial role in various industrial applications. It is primarily used as a fuel and as a raw material in the production of chemicals like vinyl chloride, acetic acid, and acrylics. Additionally, acetylene is used in oxy-acetylene welding and cutting processes, making it one of the most important industrial gases globally.

The acetylene price trend Analysis, like other industrial gases, is influenced by multiple factors, including raw material costs, energy prices, market demand, production methods, and transportation costs. Understanding these factors is crucial for businesses involved in acetylene-related industries, as price volatility can significantly impact production costs and profitability.

What is Acetylene and How is it Produced?

Acetylene is produced through various methods, the most common of which is the reaction of calcium carbide (CaC₂) with water. This process produces acetylene gas and calcium hydroxide (Ca(OH)₂) as a byproduct. The chemical reaction is as follows:

CaC2+2H2O→C2H2+Ca(OH)2\text{CaC}_2 + 2 \text{H}_2\text{O} \rightarrow \text{C}_2\text{H}_2 + \text{Ca(OH)}_2CaC2+2H2O→C2H2+Ca(OH)2Calcium carbide is derived from limestone and coke in an electric furnace, which requires significant energy input. Acetylene is often produced in on-site facilities to meet the needs of specific industries, such as welding and chemicals manufacturing.

Key Applications of Acetylene

Acetylene is used in various industries and applications, including:

- Welding and Cutting: Acetylene, when mixed with oxygen, produces a flame with extremely high temperatures, making it ideal for cutting and welding metals in industries such as construction, automotive manufacturing, and shipbuilding.

- Chemical Synthesis: Acetylene is a key feedstock for the production of chemicals like vinyl chloride, acetic acid, and acrylics, which are used in a wide range of applications, including plastics, paints, and adhesives.

- Lighting: Historically, acetylene was used in carbide lamps for lighting purposes, particularly in mining and railway applications.

- Pharmaceuticals and Other Specialty Applications: Acetylene is also used in smaller quantities for specialty chemicals and applications, including in the pharmaceutical industry for the production of certain active ingredients.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/acetylene-price-trends/pricerequest

Factors Influencing Acetylene Prices

The price of acetylene can fluctuate based on several interconnected factors. The most important determinants of acetylene prices include:

1. Raw Material Costs

The primary raw material used in the production of acetylene is calcium carbide. The price of calcium carbide is influenced by the cost of raw materials such as limestone and coke, which are required for its production. If the price of limestone, coal, or petroleum rises, it can lead to higher production costs for calcium carbide and, consequently, acetylene.

Additionally, the price of other raw materials used in acetylene production, such as oxygen or hydrogen, can also affect acetylene costs, particularly in industries where acetylene is used in chemical manufacturing.

2. Energy Prices

Acetylene production is highly energy-intensive. The process of producing calcium carbide in electric furnaces requires a significant amount of electricity. Therefore, fluctuations in energy prices—particularly electricity and natural gas—directly impact acetylene production costs. A rise in energy prices can drive up the cost of acetylene, especially in regions where energy is a significant portion of production costs.

For example, during periods of high oil prices, the costs of energy inputs such as natural gas and electricity can increase, pushing acetylene prices higher. In contrast, when energy prices drop, producers may be able to lower their acetylene prices accordingly.

3. Demand from Key Industries

The demand for acetylene is strongly linked to the performance of key industries such as welding and cutting, chemical manufacturing, and automotive production. If these industries experience growth or a surge in production, the demand for acetylene rises, leading to price increases.

- Welding and Cutting: The global construction, automotive, and manufacturing sectors rely on acetylene for welding and cutting applications. As these sectors expand, particularly in developing countries, the demand for acetylene increases, pushing prices upward.

- Chemical Manufacturing: Acetylene is a key raw material in the production of chemicals like vinyl chloride and acetic acid. Therefore, fluctuations in the demand for these chemicals, driven by industrial and consumer needs, have a significant impact on acetylene prices.

In times of economic boom, the demand for acetylene tends to rise, while in periods of recession or industrial slowdown, demand can decrease, leading to price drops.

4. Supply Chain and Logistics

Acetylene is typically produced and consumed on-site in many industries due to its flammability and storage challenges. The transportation of acetylene also requires specialized equipment and safety measures, which can add to the overall cost.

Additionally, disruptions in the supply chain—such as shortages of key raw materials (e.g., limestone, coke, or oxygen), labor strikes, or transportation bottlenecks—can drive up the price of acetylene. For example, during the COVID-19 pandemic, many industrial supply chains were disrupted, leading to temporary price hikes for various industrial gases, including acetylene.

5. Environmental Regulations

Environmental regulations, especially those targeting carbon emissions and air quality, can influence the price of acetylene. In some regions, regulations require the installation of pollution control equipment in acetylene production plants. The costs associated with compliance can lead to higher production costs, which may be passed on to consumers in the form of higher acetylene prices.

Additionally, acetylene production can have a significant carbon footprint due to the energy-intensive processes involved in its manufacture. If stricter environmental regulations are implemented to reduce emissions, manufacturers may be required to invest in cleaner technologies, which could further drive up prices.

6. Global Economic Conditions

The overall state of the global economy also plays a crucial role in acetylene price trends. In periods of economic growth, the demand for acetylene tends to increase as industrial production and construction activities rise. Conversely, during economic recessions, industrial activity typically slows down, which leads to a decrease in the demand for acetylene.

Global trade dynamics and geopolitical events also impact the acetylene market. For example, trade disputes, sanctions, or supply chain disruptions caused by geopolitical tensions can increase raw material costs and lead to higher acetylene prices.

7. Technological Advancements

Technological developments in the production process of acetylene or calcium carbide can influence its price. For instance, innovations that increase production efficiency, reduce energy consumption, or lower raw material requirements could lower the cost of acetylene production.

Conversely, the need for investment in new technologies or infrastructure to meet environmental regulations could raise production costs, which would likely be reflected in acetylene prices.

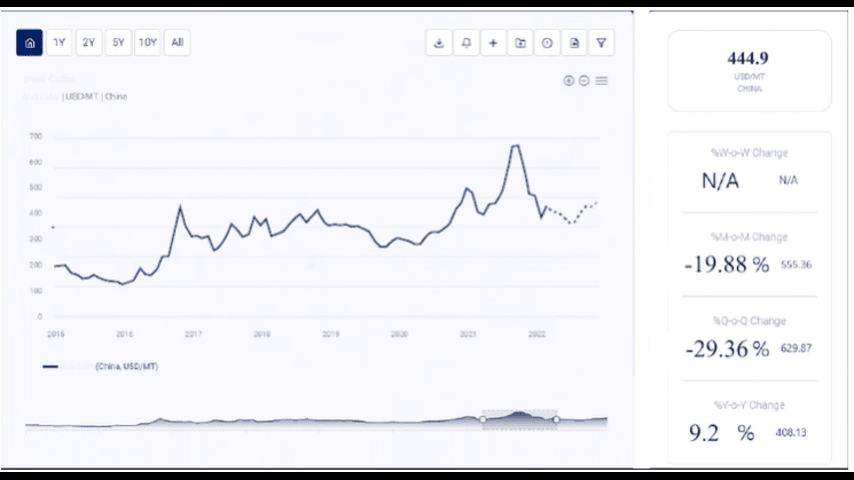

Recent Price Trends

In recent years, acetylene prices have experienced volatility due to fluctuating raw material costs, energy prices, and demand from key industries.

-

2019-2020 Price Stability: Prior to the COVID-19 pandemic, acetylene prices were relatively stable, with occasional upward pressure due to rising energy costs and demand from the chemical industry. Prices were generally moderate, with slight fluctuations based on changes in raw material and energy costs.

-

COVID-19 Impact: The pandemic caused significant disruptions to industrial production and supply chains in 2020, leading to a drop in demand for acetylene. Many industries, including automotive and construction, slowed down or temporarily halted operations, reducing the need for acetylene. As a result, prices dropped in certain regions. However, as some industries (such as chemicals) continued production, acetylene prices in those sectors remained relatively stable or experienced mild fluctuations.

-

Post-Pandemic Recovery: As economies began to recover in 2021, acetylene demand surged, particularly in industries like construction, automotive, and chemicals. This recovery led to higher acetylene prices as producers worked to meet growing demand. Additionally, supply chain disruptions and rising energy prices further pushed acetylene prices upward.

-

Recent Trends in 2023-2024: In 2023, acetylene prices saw continued upward pressure due to rising energy prices, particularly natural gas and electricity, which impacted production costs. Additionally, the global recovery of industries like welding and cutting, chemical manufacturing, and automotive production contributed to higher demand and, consequently, higher acetylene prices.

Future Outlook

The price trend for acetylene is expected to be influenced by several key factors in the coming years:

-

Economic Growth in Emerging Markets: Continued industrialization and infrastructure development in emerging economies will likely drive demand for acetylene. The increasing need for welding, cutting, and chemical manufacturing in these regions could contribute to price increases.

-

Energy Price Volatility: As acetylene production is highly energy-intensive, fluctuations in global energy prices—particularly oil, natural gas, and electricity—will continue to impact acetylene prices. A significant increase in energy prices could lead to higher acetylene costs.

-

Technological Innovations: Advances in production technologies that reduce energy consumption and improve production efficiency could help mitigate some price increases. However, investments in cleaner technologies to meet environmental regulations could increase production costs in the short term.

-

Environmental Regulations: Stricter environmental regulations aimed at reducing industrial emissions may lead to higher production costs for acetylene manufacturers. These costs could be passed on to consumers in the form of higher prices.

-

Global Trade and Geopolitical Stability: Geopolitical events, trade disruptions, and changes in raw material supply chains will continue to influence acetylene prices. In particular, changes in trade relations between major industrialized nations could affect raw material availability and transportation costs, impacting acetylene prices.

The price of acetylene is influenced by a variety of factors, including raw material costs, energy prices, demand from key industries, environmental regulations, and global economic conditions. As acetylene is essential in a range of industrial applications, its price trend is closely tied to the performance of sectors like welding, chemicals, and manufacturing. While the market for acetylene has experienced fluctuations in recent years, the future price trend will likely be shaped by growing demand in emerging markets, rising energy costs, and technological developments in production processes. Businesses involved in acetylene production and consumption will need to monitor these factors closely to anticipate price changes and manage their operations effectively.

Contact Us:

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: sales@procurementresource.com

Toll-Free Numbers:

- USA & Canada: +1 307 363 1045

- UK: +44 7537171117

- Asia-Pacific (APAC): +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology