The Growth of Smart Materials Market: Innovations in Smart Coatings for Anti-Corrosion in Marine and Aerospace Industries

Introduction

The Smart Materials Market is rapidly evolving, driven by technological advancements that promise enhanced performance and sustainability across various sectors. Among these innovations, smart coatings with self-repairing and anti-corrosive properties are making significant strides in industries like marine and aerospace. These advanced materials not only increase the lifespan of critical assets but also reduce maintenance costs and improve safety. This article explores how these smart coatings are transforming the marine and aerospace industries, specifically focusing on their impact on corrosion prevention.

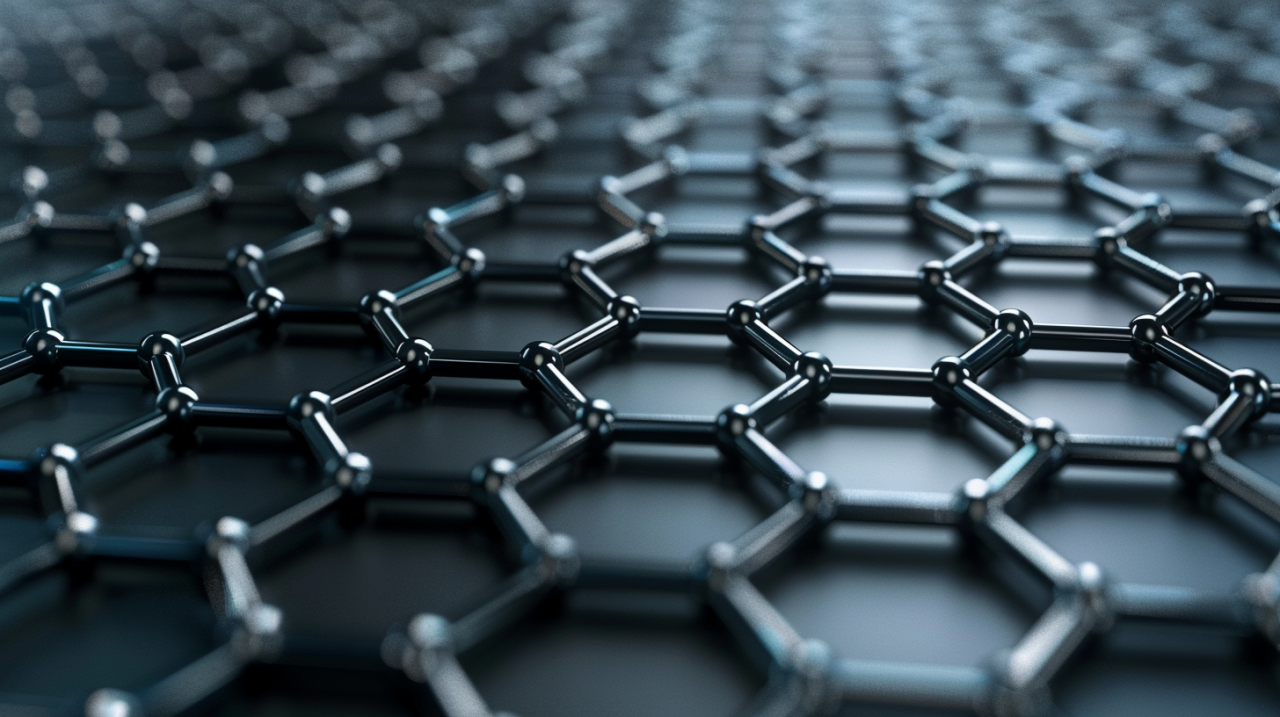

Understanding Smart Materials

Smart materials are a class of materials that respond to external stimuli such as temperature, pressure, light, or humidity. They are designed to adapt to changing environmental conditions, offering dynamic functionality. Smart coatings, a subset of these materials, are engineered to perform specific tasks such as self-healing, anti-corrosion, and damage detection. These coatings have gained traction in industries that rely on the protection and longevity of assets exposed to harsh conditions, such as marine vessels and aircraft.

The Role of Corrosion in Marine and Aerospace Industries

Corrosion is one of the most significant threats to the integrity and safety of assets in both the marine and aerospace industries. For marine vessels, saltwater environments can lead to accelerated rusting and degradation of metal surfaces. In aerospace, exposure to extreme weather conditions and high-altitude environments can cause metal fatigue, corrosion, and material failure.

Both industries invest heavily in regular maintenance and repair to mitigate the risks associated with corrosion. However, traditional methods of corrosion control, such as manual inspections and periodic coating applications, are labor-intensive and costly. Smart coatings offer a more efficient solution by actively protecting surfaces and reducing the need for frequent maintenance.

Smart Coatings with Self-Repairing Properties

One of the most promising innovations in smart materials is the development of self-repairing coatings. These coatings contain microcapsules or embedded fibers that release healing agents when the surface is damaged. The healing agents then repair the cracks or scratches, restoring the coating's integrity and ensuring continued protection against corrosion.

In the marine industry, this technology has been particularly beneficial for ships and offshore platforms. The self-repairing capabilities of these coatings help maintain a durable and corrosion-resistant surface even in the harshest oceanic environments. For aerospace applications, self-repairing coatings are used on aircraft exteriors, which can experience damage due to friction, impact, or environmental factors. The ability to self-repair extends the lifespan of these assets, reducing downtime for repairs and enhancing the overall safety of the fleet.

Anti-Corrosive Properties in Smart Coatings

Anti-corrosion coatings are designed to create a protective barrier that prevents the interaction of corrosive elements such as water, oxygen, and salts with the surface of metals. Advanced smart coatings often combine anti-corrosive agents with other functionalities like self-healing, enhancing their effectiveness in preventing corrosion over extended periods.

In marine vessels, anti-corrosive coatings play a critical role in preserving the structural integrity of ships. These coatings reduce the need for dry-docking and expensive maintenance by providing long-lasting protection against rust and deterioration. Additionally, smart anti-corrosive coatings are more environmentally friendly compared to traditional anti-corrosion treatments, as they reduce the use of hazardous chemicals and extend the life of assets, ultimately minimizing waste.

For aerospace applications, the high cost of aircraft maintenance and repair makes the use of smart coatings particularly valuable. By preventing corrosion and reducing the frequency of manual inspections and repairs, these coatings contribute to operational efficiency and safety. For example, aircraft wings and fuselage sections coated with anti-corrosive materials are better protected against moisture and environmental contaminants, ensuring longevity and reducing the risk of failure.

Impact on Longevity and Maintenance

The introduction of smart coatings with self-repairing and anti-corrosive properties is revolutionizing asset maintenance in both the marine and aerospace industries. By extending the service life of marine vessels and aircraft, these coatings reduce the frequency of repairs and replacements, resulting in significant cost savings.

In the marine industry, corrosion is responsible for a large portion of maintenance expenses. Ships and offshore platforms that are equipped with advanced smart coatings are less prone to rust, reducing the need for costly repairs and dry-docking. This increased durability not only saves money but also improves operational efficiency, as vessels can remain in service for longer periods without requiring extensive downtime.

For aerospace companies, smart coatings offer a similar advantage. Aircraft that are protected by self-repairing and anti-corrosive coatings experience fewer instances of corrosion, which reduces the need for expensive maintenance and repair cycles. Moreover, aircraft with longer lifespans help airlines optimize their fleets, reducing capital expenditures and improving overall profitability.

Technological Advancements Driving the Smart Coatings Market

The development of smart coatings is being driven by several technological advancements, including nanotechnology, polymer science, and the integration of sensors and monitoring systems. Nanomaterials, for example, enhance the performance of coatings by improving their resistance to corrosion, wear, and impact. These materials are also lightweight, which is especially important in aerospace applications where weight reduction is a key factor in fuel efficiency.

Additionally, the incorporation of sensors within smart coatings allows for real-time monitoring of the condition of the coating and the underlying material. This provides operators with valuable data on the performance of their assets, allowing them to address potential issues before they lead to failure. The integration of these advanced monitoring systems further enhances the effectiveness of smart coatings in preventing corrosion and damage.

Market Growth and Future Trends

The global smart materials market is expected to experience significant growth in the coming years, driven by the increasing demand for advanced coatings in industries like marine, aerospace, automotive, and construction. The rising focus on sustainability, cost reduction, and asset longevity is expected to propel the adoption of smart coatings, particularly in industries with high maintenance costs.

In the marine industry, the continued development of eco-friendly coatings with advanced corrosion resistance and self-healing capabilities is expected to create new opportunities for market expansion. Similarly, the aerospace industry is likely to see further adoption of smart coatings as manufacturers and operators seek ways to reduce maintenance costs and improve the safety and efficiency of their fleets.

Conclusion

Smart coatings with self-repairing and anti-corrosive properties are revolutionizing the marine and aerospace industries by providing durable, cost-effective solutions for corrosion prevention. These coatings are not only extending the lifespan of critical assets but also reducing maintenance costs and improving operational efficiency. As technological advancements continue to drive innovation in smart materials, the impact of these coatings is expected to grow, offering new opportunities for industries that rely on the protection and longevity of their assets. With the increasing focus on sustainability and cost reduction, smart coatings are poised to play a key role in shaping the future of asset maintenance and performance across various sectors.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology