A Bridge Type Cutting Machine is a powerful and versatile tool designed to cut large slabs of stone with high precision. These machines are commonly used in industries such as construction, architecture, and interior design, where stone is used for countertops, flooring, walls, and other applications. In this comprehensive guide, we’ll explore how Bridge Type Cutting Machines work, their benefits, applications, and why they are a must-have for any stone processing facility.

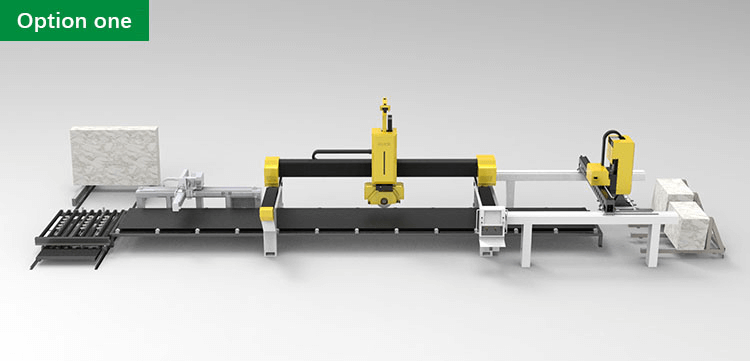

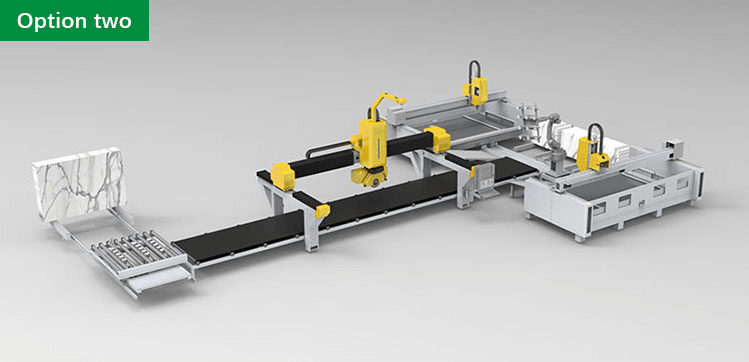

Bridge Type Stone Cutting Machine

A 5-axis stone bridge cutting machine is advanced equipment for cutting and shaping stone materials. Unlike traditional machines, which usually operate on two or three axes, a 5-axis machine moves in five directions. This allows for more complex and precise cuts, perfect for detailed work and intricate designs.

Key Components and Features

- Bridge Structure: Provides stability and support for smooth and accurate cutting.

- Cutting Head: Rotates and tilts to achieve complex angles and shapes.

- Control System: Advanced systems allow for precise programming and automation, thus reducing manual work.

- Cutting Tools: Equipped with either a water jet or diamond blade, depending on the material and desired finish.

Advantages of 5-Axis Stone Bridge Cutting Machines

Precision and Accuracy

5-axis stone bridge cutting machines offer superior precision and accuracy. Traditional cutting equipment often struggles with consistent accuracy, especially for complex designs. Thus, the 5-axis capability allows for more detailed and intricate cuts, ensuring every piece meets exact specifications.

Improved Design Capabilities

With movement in five directions, these machines can create designs impossible with traditional equipment. This capability allows architects and designers to explore more creative and complex patterns.

Efficiency and Speed

5-axis stone bridge cutting machines are much faster than traditional cutting equipment. Advanced control systems and automation reduce the need for manual work, thereby speeding up production. Consequently, this increased efficiency leads to higher productivity and lower operational costs.

Reduced Setup Time

Traditional cutting equipment often requires extensive setup and adjustment for each project. In contrast, 5-axis machines can be quickly programmed and adjusted, thereby reducing setup time and boosting overall efficiency.

Versatility

5-axis stone bridge cutting machines are highly versatile. They can handle various materials, including marble, granite, and other stones. Therefore, this versatility makes them suitable for many applications, from countertops and flooring to intricate decorative pieces.

Multi-Functional Capabilities

These machines are not limited to cutting. They can also drill, mill, and engrave, thus making them a valuable tool in any workshop.

Enhanced Safety

Safety is crucial in any industrial setting. 5-axis stone bridge cutting machines have advanced safety features that reduce the risk of accidents and injuries. Consequently, automation and precision mean operators are less exposed to hazardous conditions.

Operator Training and Safety Protocols

Traditional cutting equipment often requires extensive operator training. Advanced control systems in 5-axis machines simplify operation and improve safety. Moreover, clear safety protocols and user-friendly interfaces further enhance safe operation.

Cost-Effectiveness

Although the initial investment in a 5-axis stone bridge cutting machine may be higher than traditional equipment, long-term cost savings are significant. Increased efficiency, reduced labor costs, and lower material waste contribute to more cost-effective operations.

Long-Term ROI

The return on investment (ROI) for 5-axis machines is often higher due to their durability and low maintenance needs. As a result, businesses can expect a faster payback period and continued savings over the machine’s lifespan.

Applications and Case Studies

Architectural Applications

5-axis stone bridge cutting machines are widely used in architecture. Their ability to create intricate designs and shapes makes them ideal for custom projects, such as decorative façades, intricate columns, and detailed moldings.

Case Study: A Landmark Building

A notable example is using 5-axis stone cutting machines in constructing a landmark building. The architects needed precise and complex stonework achievable only with a 5-axis machine. Consequently, the result was a stunning façade that became a defining feature of the building.

ndustrial Applications

In industrial settings, 5-axis stone bridge cutting machines manufacture various stone products, including countertops, tiles, and other construction materials. Their speed and precision ensure high-quality products with minimal waste.

Case Study: Large-Scale Manufacturing

A large-scale manufacturing company invested in several 5-axis stone bridge cutting machines to improve its production line. Consequently, the machines significantly increased their output and reduced production costs, allowing the company to expand its market share and improve profitability.

Art and Sculpture

Artists and sculptors also benefit from 5-axis stone bridge cutting machines. These machines allow for highly detailed and intricate sculptures that would be challenging with traditional tools.

Case Study: Modern Sculpture

An artist used a 5-axis stone bridge cutting machine to create a modern sculpture with complex geometric patterns. The precision and versatility of the machine enabled the artist to bring their vision to life, resulting in a piece that gained widespread acclaim.

5 Axis Bridge Saw

5 axis CNC bridge saw is an automatic stone machining equipment that can complete the processing of pentahedron special-shaped curved surfaces at one time through five-axis linkage control, that is, three linear moving axes and two rotating axes.

It is a type of Automatic CNC Machine tailor-made for the majority of stone fabricators by IGOLDENCNC in order to meet the cutting plans of stone machining manufacturers. It has various processing modes of cutting, milling, engraving, and drilling. The bridge saw features with multiple functions, small footprint, simple operation, precise cutting, quick and convenient conversion of different functions.

Bridge Stone Saw Application

The 5 axis CNC stone bridge saw is good at cutting, milling, chamfering and edging quartz, marble, artificial stone and slabs in regular and irregular shapes. It can realize countertop cutting, bridge cutting, roman column cutting, arc line cutting, concave-convex cutting, and irregular edge cutting and milling. The automatic stone cutting bridge saw can process products of sanitary ware, stone furniture, interior decoration, and other fields. For example, wash basins, bathroom countertop, stone tables, dinning tables, kitchen tables, kitchen cabinet basins, background wall, roman edge stone decorations, etc.