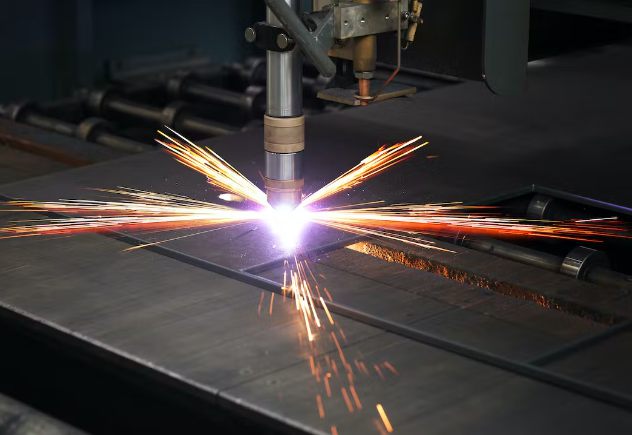

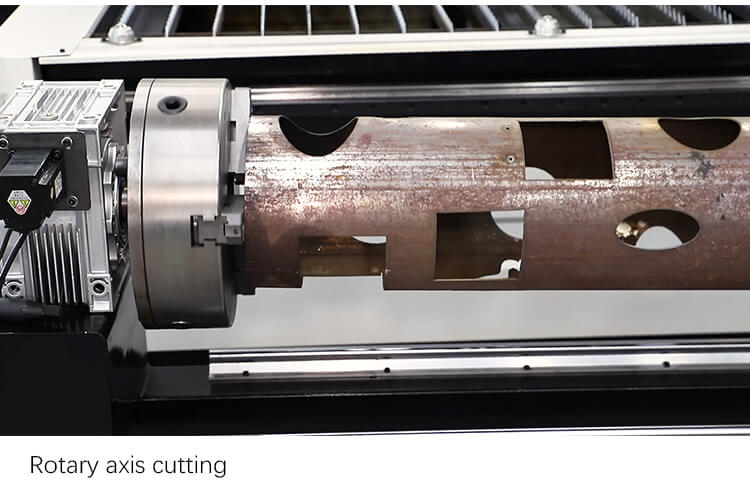

The CNC plasma cutter machine can not only meet 80% of the needs of large-scale flat cutting, but also 20% of the needs of tube cutting. It is equipped with an advanced tube-sheet dual-use CNC cutting system and a tube-sheet dual-use CNC cutting system.The software realizes the efficient and convenient interchange of cutting methods while cutting the tube and sheet material, which can not only meet the needs of users for cutting round and square tubes but also meet the special-shaped processing of steel plates.

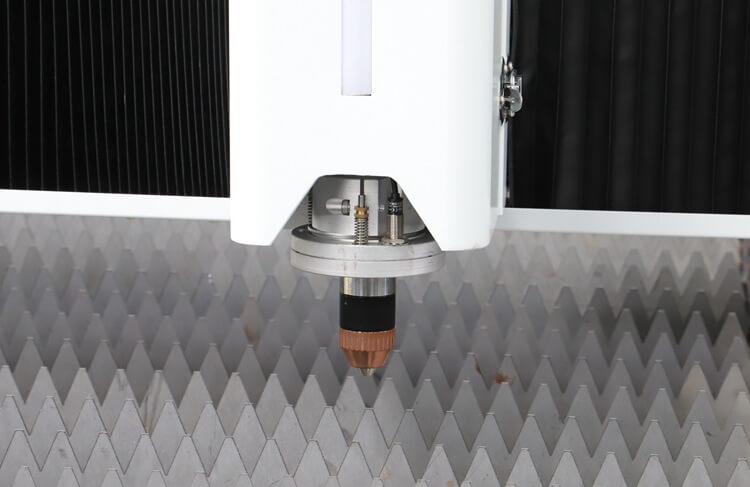

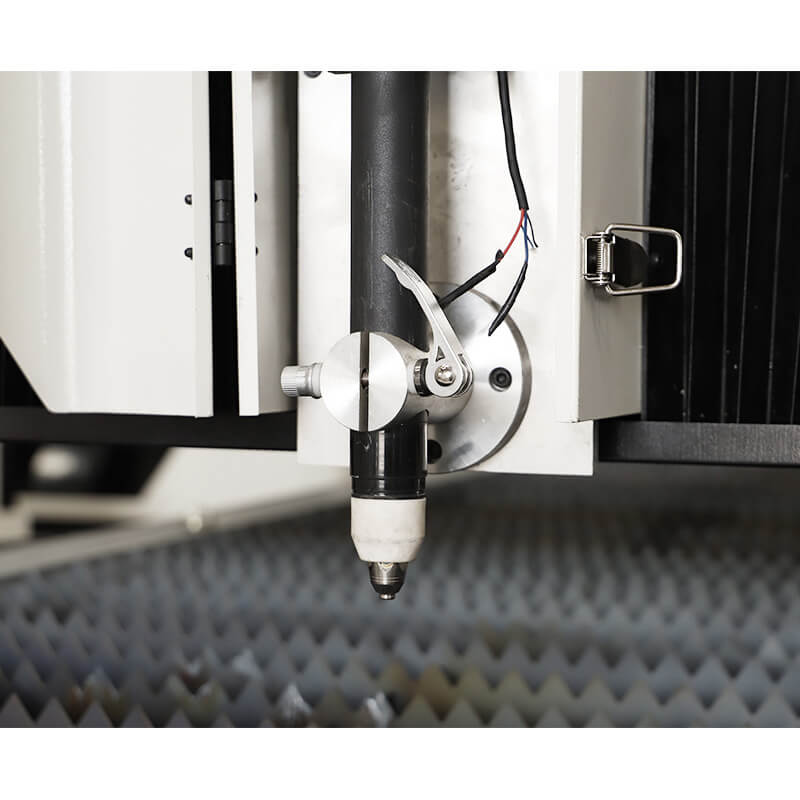

iGP-4A is a perfect solution for cutting sheet metal and tubing materials. It contains two parts: the main construction and the pipe cutter attachment. The former is a conventional table type plasma cutting machine, which is used to meet the cutting requirements of various metal plates. The pipe cutting attachment is a rotary system for cutting, notching, and piercing with square/round pipes. It comes with one plasma cutting torch in our default version. By using a servo motion system, it features excellent acceleration and deceleration.

All-purpose cnc table plasma cutter for square/round tubing and sheet metal cutting for sale with a favorable cost now.

Plasma Table for Sheet Metal and Metal Pipe with 4th Rotary Axis

- Material Versatility: CNC table plasma cutters are versatile and can cut a wide range of materials, including steel, aluminum, stainless steel, and other metals. This makes them suitable for various applications.

- Cutting Profiles: One of the key advantages of these machines is the ability to create complex and accurate profiles. They can cut straight lines, curves, bevels, and holes in the material.

- Tube Cutting: Some CNC table plasma cutters are equipped with features that allow them to cut square and round tubing. Special attachments and chucks hold the tubing securely in place while it is cut.

- Sheet Metal Cutting: These machines are also ideal for cutting sheet metal. The CNC system can follow precise design patterns to create intricate shapes and contours in the metal sheets.

- Computer Control: The CNC system is programmed to control the movement of the cutting torch. Operators use specialized software to create or import designs, which are then converted into toolpaths for cutting. Proficiency in the use of CNC software is essential.

- Accuracy and Precision: CNC table plasma cutter offer high precision and accuracy. They can consistently produce high-quality cuts, reducing the need for manual finishing or additional processing.

- Efficiency: CNC table plasma cutters are known for their efficiency. They can cut materials at a faster rate than manual methods, making them suitable for large-scale production.

- Quality Control: After cutting, it’s important to inspect the cut pieces for accuracy and quality. Additional steps, such as deburring or cleaning the cut edges, may be necessary.

CNC Table Plasma Cutting Machine Application

Plasma cutting machine is suitable for cutting kinds of metal materials like low carbon steel, round metal tube, alloy steel, and non-ferrous metal and for the industries related to metal cutting, such as boiler pressure container manufacturing, chemical container manufacturing, industrial power station construction, metallurgy, chemicals, aviation, and aerospace industry, automobiles and vehicle manufacturing, construction and so on.

CNC table plasma cutter are widely used in industries such as metal fabrication, construction, and manufacturing. They provide a cost-effective and efficient way to cut various types of metal materials. When using these machines, operators need to be knowledgeable about the specific cutting parameters, tool settings, and material properties to achieve the desired results.