Undercarriage Components Market Facing Market Disruptions Due To Supply Chain And Raw Material Issues

Posted 2025-03-05 05:16:04

0

4

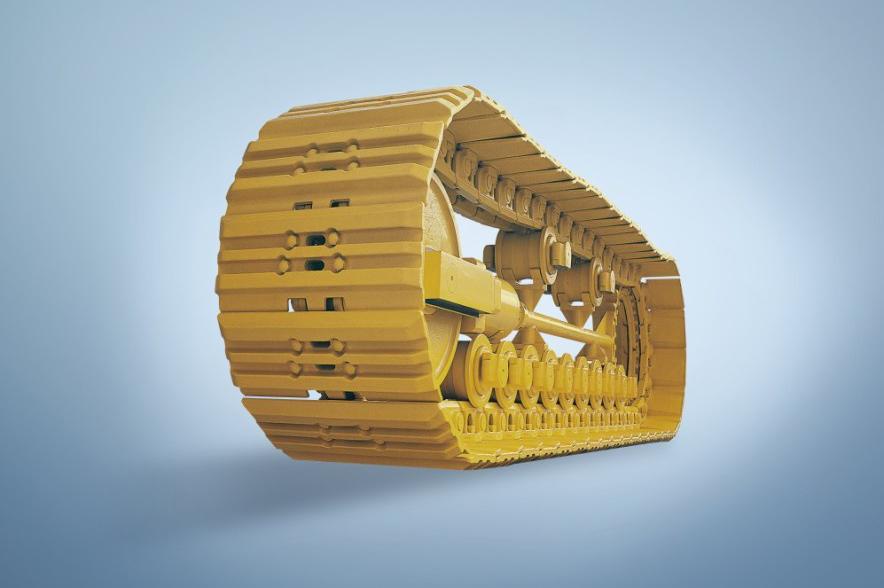

The undercarriage components market is undergoing significant disruptions due to fluctuating raw material prices, supply chain instability, and evolving industry demands. These disruptions impact manufacturers, suppliers, and end-users, creating uncertainties in production, pricing, and availability of key components. With industries like construction, mining, and agriculture relying heavily on undercarriage components, market disruptions pose challenges to business continuity and operational efficiency. As the industry adapts to new challenges, companies must focus on strategic solutions to mitigate risks and sustain growth in the coming years.

Impact Of Raw Material Shortages

- Steel price volatility affecting the cost of manufacturing undercarriage components

- Shortage of high-quality rubber impacting the production of track shoes and rollers

- Dependence on global suppliers leading to procurement delays and increased lead times

- Geopolitical conflicts disrupting the supply of essential raw materials

- High transportation costs due to fuel price hikes adding to production expenses

Supply Chain Bottlenecks Affecting Market Growth

- Limited availability of critical components causing delays in machinery production

- Port congestion leading to shipment delays for undercarriage components

- Shortage of skilled labor in manufacturing units affecting production timelines

- Dependence on specific regions for raw materials creating vulnerability in the supply chain

- Increased logistics costs making undercarriage components more expensive for buyers

Disruptions In Manufacturing And Production Processes

- Factory shutdowns due to labor strikes causing production slowdowns

- Technological shifts requiring new machinery and retraining of workforce

- Inconsistent energy supply affecting manufacturing operations in key industrial zones

- Implementation of stringent environmental regulations impacting material sourcing and production methods

- Rising operational costs due to inflation reducing profit margins for manufacturers

Evolving Market Demand Creating Uncertainties

- Shift toward electric and hybrid machinery reducing demand for traditional undercarriage components

- Growing preference for rental and leasing services over purchasing new equipment

- Increasing adoption of automation leading to changes in component specifications

- Variations in construction and mining activities affecting regional market demands

- Higher expectations for durability and performance increasing pressure on manufacturers

Regulatory Challenges Impacting Market Stability

- Stricter emission norms requiring the use of eco-friendly materials in production

- Changes in trade policies affecting import and export of undercarriage components

- Compliance with international safety standards increasing production costs

- New labor laws influencing workforce management in manufacturing plants

- Implementation of sustainability initiatives altering traditional manufacturing processes

Technological Disruptions Altering Industry Dynamics

- Integration of IoT-based monitoring systems requiring new component designs

- Advancements in 3D printing impacting conventional manufacturing methods

- Use of AI in predictive maintenance reducing demand for frequent replacements

- Shift toward lightweight materials affecting traditional steel-based undercarriage components

- Increased investment in R&D driving rapid changes in component development

Fluctuations In Market Pricing And Profit Margins

- Higher raw material costs leading to increased prices of undercarriage components

- Competition among manufacturers resulting in price wars and reduced margins

- Impact of currency exchange rates on import and export pricing

- Unstable demand from end-users causing inconsistent revenue streams

- Discounts and promotional offers reducing profitability for component suppliers

Economic Instability Creating Uncertainty In Investments

- Global economic downturns affecting capital expenditure on heavy machinery

- Uncertain interest rates impacting financing options for equipment manufacturers

- Reduction in infrastructure spending slowing down demand for undercarriage components

- Investors shifting focus to alternative industries due to unpredictable market trends

- Cost-cutting measures by major players leading to downsizing of production capacities

Impact Of Climate Change And Environmental Concerns

- Extreme weather conditions affecting mining and construction activities

- Regulations promoting sustainable manufacturing increasing production costs

- Transition toward eco-friendly machinery changing component requirements

- Need for climate-resilient materials influencing R&D investments

- Increased demand for energy-efficient components adding pressure on manufacturers

Global Trade Conflicts And Their Effects On The Market

- Trade restrictions causing disruptions in component imports and exports

- Tariffs increasing the overall cost of undercarriage components for end-users

- Political instability affecting business relationships with international suppliers

- Sanctions on key raw material suppliers limiting production capabilities

- Changing trade agreements creating unpredictability in market operations

Adoption Of Alternative Materials And Manufacturing Methods

- Rising popularity of composite materials reducing reliance on traditional metals

- Increased use of automation in production lines improving efficiency but requiring high initial investments

- Growth of sustainable manufacturing techniques impacting traditional supply chains

- Use of recycled materials in component production to meet environmental regulations

- Development of modular undercarriage systems enhancing flexibility and cost-effectiveness

Shifts In Consumer Preferences Affecting Market Trends

- Higher demand for extended lifespan components reducing frequent replacements

- Customization requests increasing complexity in manufacturing processes

- Preference for low-maintenance solutions affecting sales of traditional parts

- Expansion of aftermarket services due to increased focus on equipment maintenance

- Greater emphasis on warranty and service agreements altering pricing strategies

Future Outlook Amid Market Disruptions

- Increased collaboration between manufacturers and raw material suppliers to ensure steady supply chains

- Adoption of digital solutions for real-time monitoring of undercarriage component performance

- Expansion into emerging markets to counter regional demand fluctuations

- Investment in research and development to create more resilient and cost-effective components

- Strategic partnerships between key players to mitigate risks and enhance market stability

Search

Categories

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology

Read More

Autonomous Emergency Braking Market Size, Share, Trends and Forecast by 2030

This Autonomous Emergency Braking market report has been prepared by considering...

200ah lifepo4 battery

Unraveling the strength of 12V 150Ah and 12V 20Ah Lithium Battery packs In today's planet, in...

Dry Mouth Relief Market Size, Top Players, Trends, Growth Dynamics and Industry Forecast 2032

The Unnatural Amino Acids Market is experiencing rapid expansion, fueled by the growing...

Electron Beam Machining Market Leading Countries, Growth, Drivers, Risks, and Opportunities Forecast 2024 - 2031

This Electron Beam Machining Market sector is rapidly evolving, with substantial growth...

Compliance Data Management Market Size, Share, Demand, Key Drivers, Development Trends and Competitive Outlook

"Global Compliance Data Management Market - Size, Share, Industry Trends, Demand and...