Maximizing Efficiency with Hydro Cyclone Washing in Mining & Construction

In mining and construction, washing equipment plays a crucial role in ensuring high-quality materials and efficient operations. Removing impurities, refining raw materials, and improving overall product quality are essential processes in these industries. One of the most effective solutions for washing and separating materials is Mining Washing Equipment, particularly hydrocyclones. Hydrocyclone Efficiency significantly impacts both mining and construction sectors by improving productivity, reducing waste, and conserving resources. This article explores hydro cyclone washing technology and how it optimizes performance in these industries.

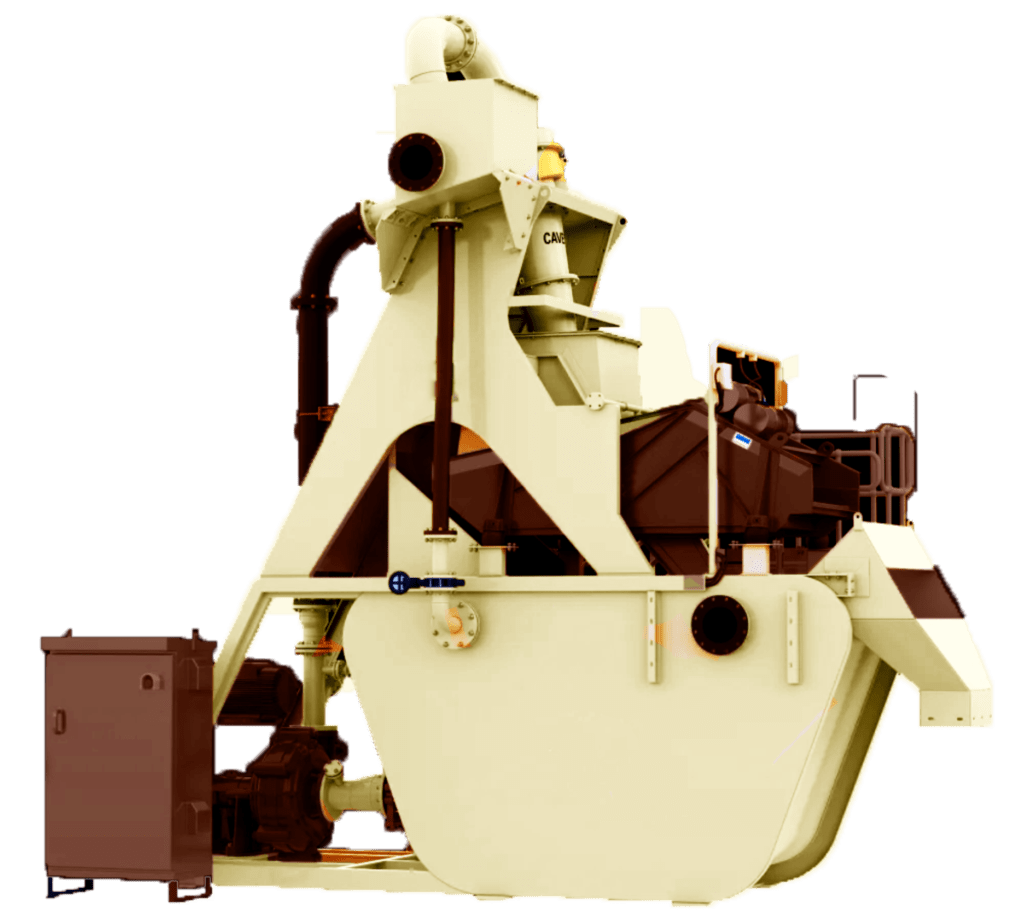

Understanding Hydro Cyclone Washing Technology

A hydrocyclone is a device used to separate particles in a liquid suspension based on density and size. It works by creating a high-speed rotational flow inside a conical chamber, where heavier particles are pushed to the outer wall and collected at the bottom, while lighter particles exit through the top.

Mining Hydrocyclones help in separating valuable minerals from waste materials, ensuring higher ore recovery. In Construction Aggregate Washing, hydrocyclones remove fine particles like silt and clay from sand and gravel, improving the quality of construction materials. Hydrocyclone separators are widely used due to their ability to handle large volumes of material efficiently.

Hydro cyclone technology offers several benefits over traditional washing methods. It provides higher separation efficiency by removing unwanted particles more effectively. It also conserves water as it requires less water compared to conventional washing systems. Additionally, its compact design requires less space and is easy to integrate into existing systems. Moreover, hydrocyclones have fewer moving parts, leading to lower maintenance costs.

Importance of HydroCyclone Washing in Mining

Hydrocyclones play a vital role in improving mineral recovery rates by efficiently separating valuable minerals from waste. They are used in processes such as dewatering, classification, and desliming.

Hydro cyclone washing improves ore quality by effectively removing impurities from ore, increasing its value. It enhances metal recovery by efficiently separating fines and reduces energy consumption in downstream processing.

A mining company implemented hydrocyclone washing technology in its ore processing plant and saw remarkable improvements. The company experienced a 15% increase in ore recovery rates, a 30% reduction in water usage, and enhanced efficiency of downstream equipment like crushers and screens.

Hydro Cyclone Washing in Construction Aggregate Processing

High-quality construction materials ensure durability and strength in infrastructure projects. Removing impurities from aggregates helps achieve the required standards.

Hydrocyclones have a significant impact on sand and gravel washing. They produce cleaner, more uniform aggregates, reduce contamination, and lead to stronger concrete and asphalt mixtures. Additionally, hydrocyclones increase operational efficiency by minimizing waste.

One of the major advantages of hydro cyclone washing is water conservation. Hydrocyclones recycle water, reducing overall consumption. They also minimize environmental impact by decreasing sediment discharge into natural water bodies, making them a sustainable choice for aggregate washing.

Maximizing Hydrocyclone Efficiency in Industrial Applications

Several factors affect Hydrocyclone Efficiency, including proper feed pressure and flow rate, the correct cyclone size for the application, and regular maintenance to prevent blockages.

To optimize hydrocyclone performance, industries must adopt best practices such as periodic monitoring of underflow and overflow quality, adjusting operational parameters based on material properties, and using multiple hydrocyclones in parallel to handle large volumes.

Hydrocyclone washing comes with certain challenges, including clogging, inconsistent particle separation, and high wear and tear. Regular cleaning and monitoring can prevent blockages, while adjusting pressure and feed rate ensures better efficiency. Using wear-resistant materials extends equipment life and minimizes maintenance requirements.

Advanced Mining Washing Equipment: Choosing the Right Solution

When selecting the best Mining Washing Equipment, it is essential to consider features such as high separation efficiency, low energy and water consumption, and durable materials for extended operational life.

Hydrocyclone Separators offer significant advantages over traditional washing systems. They consume less water, provide higher efficiency, require lower maintenance, and occupy less space. In contrast, traditional washing systems require high water consumption, moderate efficiency, frequent maintenance, and larger space.

Recent industry innovations have further improved hydrocyclone technology. These include smart sensors for real-time monitoring, advanced materials to reduce wear and tear, and AI-based optimization for improved efficiency.

Role of Leading Crusher & Feeder Manufacturers in Efficient Washing

The Best Stone Crusher Plant plays an integral role in Hydro Cyclone Washing by processing raw material before washing. Proper integration ensures efficient removal of dust and fines, which ultimately improves aggregate quality.

The Best Vertical Shaft Impactor (VSI) supports efficient material processing by crushing materials into uniform sizes, improving washing efficiency. VSI reduces oversized particles and enhances the final product quality.

The Best Jaw Crusher Manufacturer contributes to mining efficiency by providing primary crushing before hydrocyclone separation. Jaw crushers ensure consistent feed size and reduce unnecessary fines, optimizing the overall process.

The Best Grizzly Feeder Manufacturer also plays a key role in material screening and washing. Grizzly feeders pre-screen materials before washing, preventing clogs in hydrocyclones. This process reduces waste and improves operational efficiency.Craftsmen Crusher Industries integrates advanced crushing and screening equipment to enhance washing performance.

Conclusion

Hydro cyclone washing has transformed mining and construction aggregate processing. By integrating Mining Washing Equipment like Hydrocyclone Separators, industries can improve material quality, reduce waste, and optimize efficiency.

With advancements in hydrocyclone technology and the right equipment, businesses can achieve sustainable and cost-effective operations. Investing in high-quality washing solutions from Craftsmen Crusher Industries ensures long-term success in mining and construction sectors.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology