How is General Electric Driving Innovation in the Motor Monitoring Market? Exploring Strategies, Emerging Technologies, and Developments

Introduction:

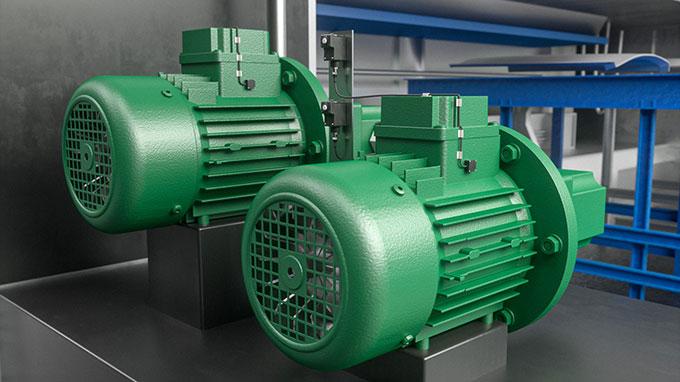

General Electric Company (GE) has long been recognized as a leader in industrial technologies, powering innovations across sectors such as energy, healthcare, and aviation. One of its core focuses in recent years has been on revolutionizing the industrial maintenance landscape with cutting-edge motor monitoring technologies. As industries around the world move toward predictive maintenance, energy efficiency, and digital transformation, GE is well-positioned to lead the charge in this area, capitalizing on emerging innovations and adapting new strategies to stay at the forefront of the Motor Monitoring Market.

How is General Electric Adapting to the Motor Monitoring Market?

General Electric's approach to the motor monitoring market is multifaceted, involving both innovative technologies and strategic acquisitions. GE recognizes the growing demand for real-time monitoring and predictive maintenance, particularly in the context of industrial operations that rely heavily on motors. By embracing digital transformation and automation, GE has set the stage for significant advancements in the motor monitoring sector.

1. Strategic Acquisitions and Partnerships

To strengthen its position in the motor monitoring market, GE has consistently focused on acquiring companies that offer complementary technologies and expertise. A significant example is GE’s acquisition of ServiceMax in 2017, a leading provider of cloud-based field service management software. This acquisition expanded GE’s capabilities to deliver comprehensive solutions for industrial maintenance, including motor monitoring, through data analytics and real-time insights.

By integrating ServiceMax’s service management platform with GE's existing technologies, the company has developed a robust suite of services for predictive maintenance, performance monitoring, and remote diagnostics. The acquisition has allowed GE to offer more integrated solutions for industries such as power generation, manufacturing, and transportation.

Additionally, GE’s partnerships with other technology players have enabled the development of cutting-edge motor monitoring systems. Collaborations with firms specializing in artificial intelligence (AI), Internet of Things (IoT), and machine learning (ML) have helped GE enhance its monitoring solutions to predict motor failures more accurately and optimize performance.

2. Industrial IoT Integration

One of the most significant trends in the motor monitoring market is the integration of Industrial Internet of Things (IIoT) technologies, and General Electric is at the forefront of this revolution. GE’s Predix platform, a cloud-based industrial IoT solution, is designed to enable industries to monitor equipment and machinery performance in real-time, including motors. The Predix platform allows users to collect and analyze vast amounts of data from industrial assets, helping to identify inefficiencies, detect potential issues, and implement predictive maintenance strategies.

The integration of IIoT into GE’s motor monitoring solutions provides businesses with actionable insights that can significantly reduce downtime and improve operational efficiency. With Predix, GE offers a unified platform for data visualization, analytics, and decision-making, empowering companies to optimize motor performance and extend the life of their assets.

Furthermore, GE’s IIoT technologies support the seamless integration of sensors into motors, allowing companies to monitor key parameters like vibration, temperature, and power consumption in real-time. This capability is critical for early detection of faults, enabling preventive measures before a motor failure occurs.

3. Predictive Maintenance and AI-driven Analytics

General Electric has heavily invested in predictive maintenance as a key component of its motor monitoring strategy. Traditional maintenance approaches such as scheduled or reactive maintenance often lead to inefficiencies and increased costs. In contrast, predictive maintenance uses data analytics and machine learning to predict motor failures before they happen, minimizing unplanned downtime and reducing maintenance costs.

By leveraging artificial intelligence (AI) and machine learning (ML), GE’s motor monitoring systems continuously learn from motor performance data and detect patterns that indicate early signs of wear and tear. GE’s AI algorithms analyze real-time data from sensors embedded in motors, identifying anomalies in motor performance that could signal potential problems such as overheating, misalignment, or lubrication issues.

AI-driven analytics help to provide highly accurate predictions of when a motor is likely to fail, allowing companies to plan maintenance activities proactively. This predictive capability helps businesses avoid costly disruptions, improve productivity, and extend the life of motors. Through its AI-powered motor monitoring solutions, GE is helping industries make smarter, data-driven decisions that reduce operational risks and enhance profitability.

4. Energy Efficiency and Sustainability Initiatives

Energy efficiency has become a critical priority for businesses worldwide as they strive to reduce operating costs and minimize their environmental impact. Motors, which consume a significant portion of industrial energy, are an area where significant savings can be realized through improved monitoring and performance optimization.

General Electric’s motor monitoring systems are designed to focus on energy efficiency, ensuring that motors operate at optimal performance levels while reducing energy waste. GE’s solutions continuously track key performance indicators (KPIs) like power consumption and motor load, providing insights that help organizations optimize energy usage and identify energy-saving opportunities.

In addition, GE's commitment to sustainability is evident in its focus on helping industries reduce their carbon footprints. By improving the efficiency of motors through real-time monitoring, GE enables companies to minimize energy consumption, lower greenhouse gas emissions, and contribute to a more sustainable industrial ecosystem.

GE’s role in the renewable energy sector further strengthens its commitment to sustainability. By providing motor monitoring solutions for renewable energy projects, such as wind turbines and solar energy systems, GE is helping to optimize the performance of these green technologies. Ensuring that motors in renewable energy systems run efficiently helps improve energy output and ensures the long-term sustainability of clean energy sources.

5. Cloud-Based Solutions and Remote Monitoring

Another critical area where GE is innovating is in the development of cloud-based motor monitoring solutions. The cloud enables remote monitoring of industrial motors, allowing businesses to access real-time data from anywhere, at any time. This remote monitoring capability is particularly beneficial for companies with geographically dispersed assets or those operating in hard-to-reach locations.

By leveraging cloud computing, GE’s motor monitoring systems can aggregate data from multiple sites, providing a centralized platform for performance tracking and predictive analytics. Operators and maintenance teams can remotely monitor the health of motors, analyze performance data, and receive alerts about potential issues—all without the need for on-site visits.

This cloud-based approach also allows for the integration of additional technologies such as augmented reality (AR) for remote troubleshooting, further enhancing operational efficiency and reducing downtime. The ability to remotely monitor and manage motor health is a game-changer for industries that rely on large fleets of motors, from manufacturing plants to oil and gas operations.

6. Smart Motors and Advanced Sensor Technology

To further improve motor monitoring capabilities, GE is pushing the boundaries of sensor technology. Sensors are the backbone of any motor monitoring system, providing the data needed for real-time performance tracking. GE’s smart motors are embedded with advanced sensors that capture a wide range of metrics, including vibration, temperature, current, and voltage.

The integration of these sensors allows for more granular monitoring of motor performance, enabling businesses to detect even the most subtle changes in behavior that could indicate a developing issue. GE is also exploring the use of edge computing to process data locally at the sensor level, enabling faster analysis and reducing the need for constant data transmission to the cloud.

Conclusion

General Electric Company is leading the charge in the motor monitoring market, leveraging its expertise in industrial IoT, AI-driven analytics, predictive maintenance, and energy efficiency. By embracing emerging technologies and strategic acquisitions, GE has positioned itself as a key player in helping businesses optimize motor performance, reduce downtime, and enhance sustainability.

With the continued growth of industrial automation and digital transformation, GE’s motor monitoring solutions will remain a critical asset for industries worldwide. As the market evolves, GE’s innovative approaches and commitment to technology-driven solutions will shape the future of motor monitoring and predictive maintenance for years to come.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology