How to deal with false welding, cold welding and wicking during SMT chip processing?

SMT PCB Manufacturer chip processing plants may encounter false soldering, cold welding, and wicking problems during the processing of lead-free chips. So how can the chip processing plant solve these problems?

The first is the problem of false soldering, which is usually caused by the following reasons: poor solderability of components and pads, improper reflow soldering temperature and heating speed, incorrect printing parameters, too long stagnation time after printing, and change in solder paste activity Poor and other reasons.

The solution is as follows: strengthen the screening of PCB and components to ensure good soldering performance; adjust the reflow soldering temperature curve; change the pressure and speed of the squeegee to ensure a good printing effect; solder paste as soon as possible after printing and reflow soldering.

Next is the problem of cold welding. The so-called cold welding means that the surface of the solder joint is dark and rough, and it does not melt with the object to be welded. Generally speaking, the formation of cold welding in SMT chip processing is mainly caused by unsuitable heating temperature, deterioration of solder, excessive preheating time or excessive temperature.

General solution: adjust the curve according to the reflux temperature curve provided by the supplier, and then adjust it according to the actual situation of the produced product. Replace with new solder paste. Check whether the equipment is normal and correct the preheating conditions.

Another problem is wicking. Sn/Pb solder paste rarely occurs before, but this problem often occurs when using lead-free solder paste. This is mainly because the wetting and spreading rate of lead-free solder paste is not as good as that of lead-containing solder paste. The main reason for the wicking phenomenon is the high thermal conductivity of the component pins and the rapid temperature rise, so that the solder preferentially wets the pins, and the wetting force between the solder and the pin is much greater than the wetting force between the solder and the pad. , The upturn of the lead will aggravate the occurrence of wicking phenomenon.

The general solution: during reflow soldering, the SMA should be fully preheated and then placed in the reflow oven. Carefully check and ensure the solderability of the PCB board pads. The coplanarity of the soldered components cannot be ignored. Defective devices should not be used in production.

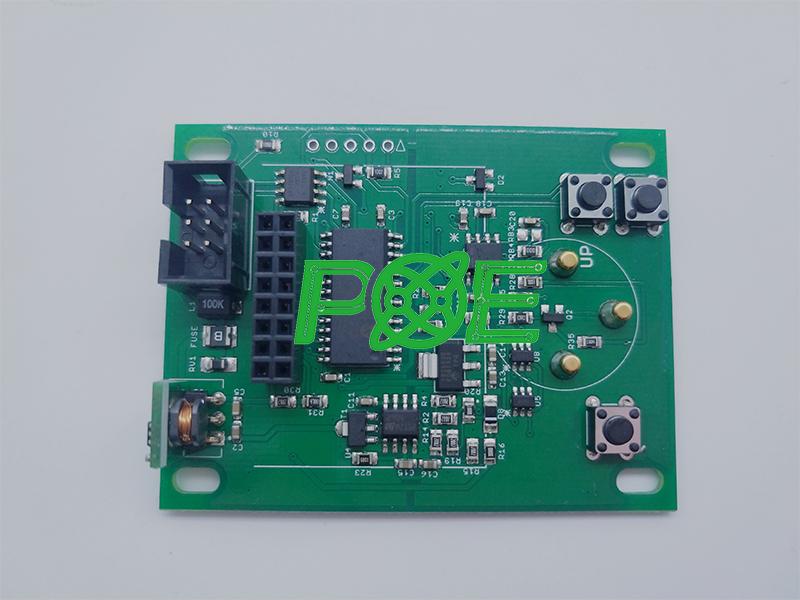

POE is an electronic processing company specializing in SMT chip processing, DIP common processing, PCBA package labor and materials, and PCB circuit board manufacturing. It has many years of electronic processing experience, as well as advanced production equipment and a complete after-sales service system. The company's SMT chip processing capacity reaches 1 million pieces per day, and the DIP plug-in processing capacity is 200,000 pieces per day,multilayer pcb manufacturing which can provide you with high-quality electronic processing services. ...

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology