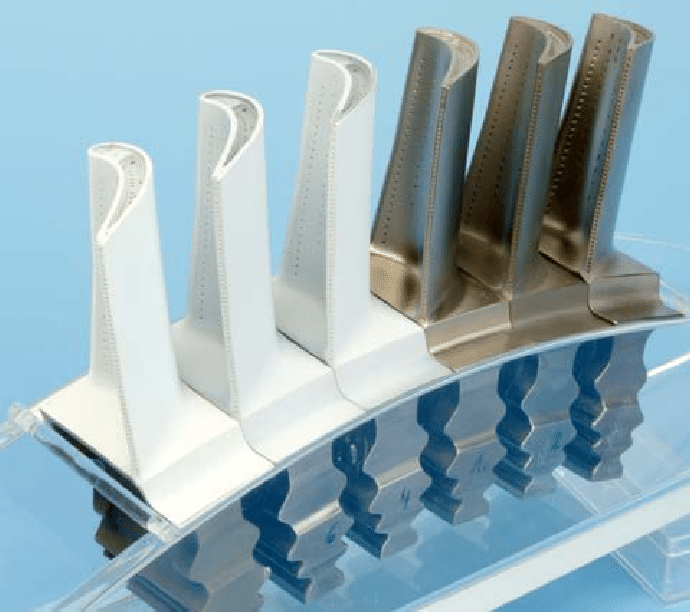

Metal Surfaces Operating At Elevated Temperatures Usually Require Thermal Barrier Coatings (TBCs)

The metal substrate, metallic bond coat, thermally generated oxide (TGO), and ceramic topcoat are the usual four layers of thermal barrier coatings. Yttria-stabilized zirconia (YSZ), which has a very low conductivity and is stable at the nominal operating temperatures normally seen in Thermal Barrier Coatings applications, is often used as the ceramic topcoat.

The highest thermal gradient of the Thermal Barrier Coatings is produced by this ceramic layer, which also keeps the lower layers cooler than the surface. The phase of YSZ, however, undergoes unfavourable phase changes beyond 1200 °C, moving from t'-tetragonal to tetragonal to cubic to monoclinic. Such phase changes result in the development of cracks in the top layer.

In recent efforts to find a replacement for the Yttria-stabilized zirconia ceramic topcoat, various innovative ceramics (such as rare earth zirconates) have been found that perform better at temperatures above 1200 °C but have less fracture toughness than Yttria-stabilized zirconia.

These zirconates could include a lot of oxygen-ion vacancies, which might promote oxygen transport and make the TGO production worse. It is possible for the coating to spall with a thick enough TGO, which is a catastrophic mode of failure for Thermal Barrier Coatings. Such coatings would need to be used in conjunction with more oxidation-resistant coatings, such alumina or mullite.

Read More - https://latesthighlightscmi.blogspot.com/2023/04/thermal-barrier-coatings-tbcs-are.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology