Precision Milled Pressure Plates: The Backbone of High-Performance Mechanical Systems

In an era where engineering precision dictates performance, the Precision Milled Pressure Plate has emerged as an unsung hero across industries. This component’s ability to maintain structural integrity under extreme conditions makes it indispensable in systems demanding reliability and accuracy.

What Is a Precision Milled Pressure Plate?

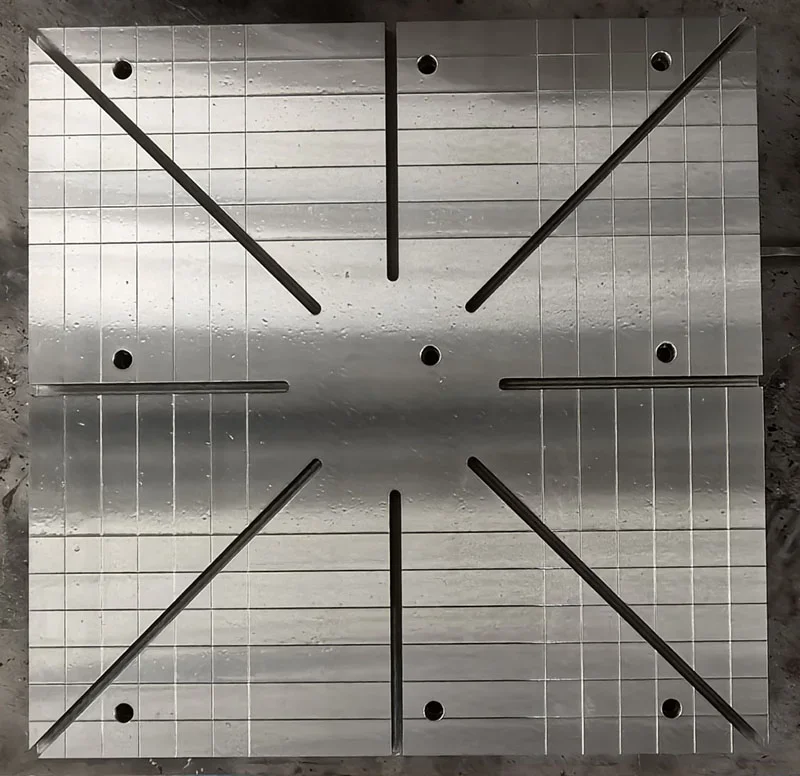

A pressure plate is a structural or functional component used to distribute load, pressure, or mechanical force evenly across a defined surface. When the term "precision milled" is added, it refers to the manufacturing process: advanced CNC milling and surface machining techniques that achieve tight dimensional tolerances and consistent flatness — often down to microns.

These components are commonly used in:

-

Automotive clutch systems

-

Hydraulic presses

-

Forging equipment

-

Brake systems

-

Die-casting and forming machines

Key Advantages of Precision Milled Pressure Plates

-

Exceptional Flatness and Parallelism

Precision milling ensures that the pressure plate provides uniform surface contact, which is critical in load distribution and sealing applications. -

Improved Durability and Wear Resistance

With hardened surfaces and optimized edge tolerances, precision milled plates resist deformation, warping, and surface fatigue under repeated stress. -

Enhanced Equipment Performance

In systems like clutches or stamping presses, a properly milled pressure plate leads to more accurate mechanical responses, less vibration, and greater reliability. -

Custom Machining Capabilities

These plates can be tailored in size, thickness, hole patterns, grooves, and surface finishes to match specific project needs.

Applications Across Industries

From automotive manufacturing to aerospace and heavy machinery, precision milled pressure plates are widely adopted due to their versatility and performance. Some typical examples include:

-

Automotive: Ensuring stable clutch engagement in high-torque engines

-

Construction Machinery: Supporting hydraulic force in press and compaction equipment

-

Tool & Die Industry: Providing uniform pressure in mold bases and forming systems

-

Renewable Energy: Assisting in composite pressing and lamination of solar panels or battery packs

-

Maintenance and Replacement Tips of the Precision Milled Pressure Plate

-

Regular Inspection: Check for surface wear, cracks, or heat marks — signs of fatigue or misalignment.

-

Precision Surface Re-grinding: In some cases, plates can be remachined rather than fully replaced to restore flatness.

-

Avoid Overloading: Use the pressure plate within its rated capacity to prevent warping or stress failure.

Final Thoughts

A https://www.nuknail.com/Precision-Milled-Pressure-Plate.html may not be the most visible part of a machine, but its impact on mechanical integrity, efficiency, and product quality is profound. Whether you’re designing a high-pressure system or maintaining critical equipment, investing in high-quality, precision-milled components ensures smoother operations and longer equipment lifespan.

For manufacturers and engineers aiming for exactness and durability, precision milled pressure plates are more than a component — they’re a foundational element of system performance.

Precision Milled vs. Standard Pressure Plates: What’s the Real Difference?

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology