Prepreg Market: Enabling the Future of Lightweight Engineering

Pre-impregnated composites, widely known as prepregs, are advanced composite materials where fibers such as carbon, glass, or aramid are pre-impregnated with a resin system. These materials are gaining increasing traction in aerospace, automotive, wind energy, sports, and electronics industries due to their superior strength-to-weight ratio, consistency, and ease of use. The global push for lightweight, durable, and sustainable solutions has propelled prepregs into the spotlight as a material of choice for next-generation engineering applications.

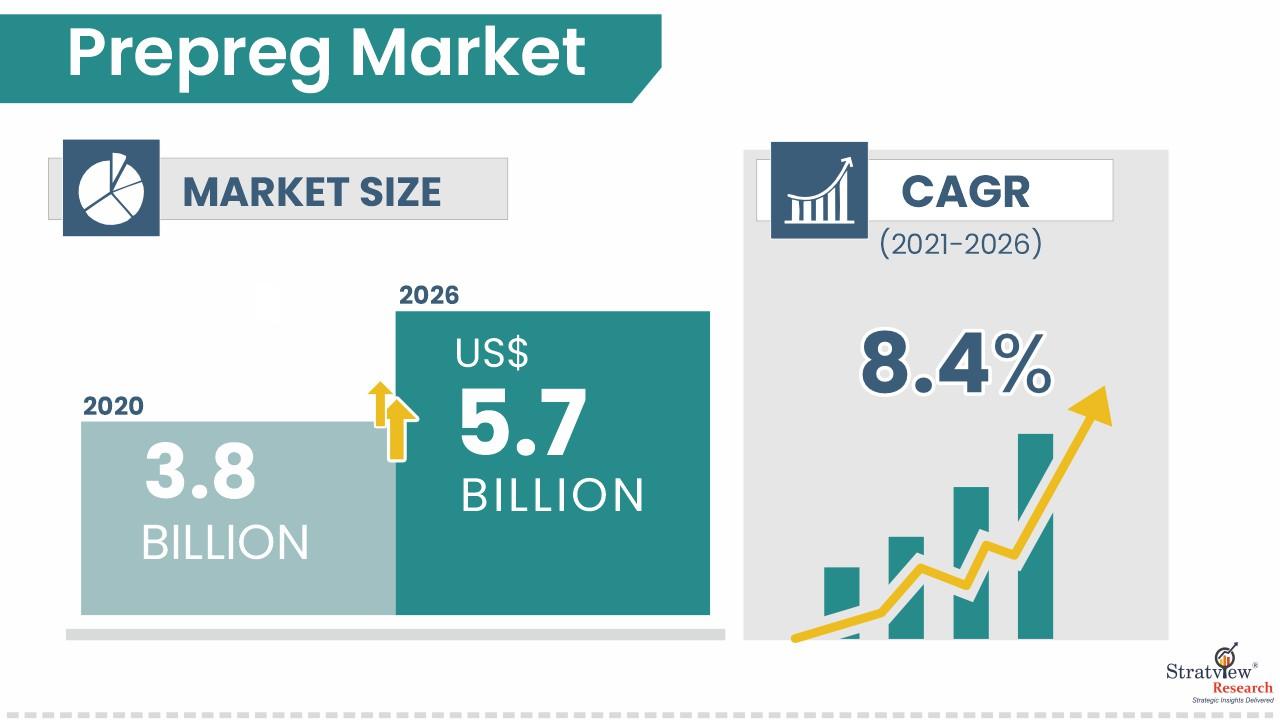

According to Stratview Research, the prepreg market was estimated at USD 3.8 billion in 2020 and is likely to grow at a healthy CAGR of 8.4% during 2021-2026 to reach USD 5.7 billion in 2026.

Download the sample report here:

https://www.stratviewresearch.com/Request-Sample/1059/prepreg-market.html#form

Key Drivers

- Rising Aerospace Demand: The aerospace industry remains the largest consumer of prepregs. Aircraft manufacturers are constantly seeking lighter and stronger materials to improve fuel efficiency and reduce emissions, and prepregs fulfill this requirement.

- Automotive Innovation: With the rise of electric vehicles (EVs) and the global focus on emission reduction, automakers are increasingly adopting prepregs for structural and interior components to reduce weight while maintaining safety and performance.

- Wind Energy Expansion: Prepregs are widely used in wind turbine blades to improve durability, fatigue resistance, and efficiency. The global transition toward renewable energy strongly supports this demand.

- Sports and Consumer Goods: Prepregs are integral to high-performance sporting equipment, ranging from bicycles to tennis rackets, due to their high strength and low weight.

- Technological Advancements: Continuous improvements in resin systems (epoxy, thermoplastic) and automated production methods are reducing costs and making prepregs more accessible to new industries.

Key Trends

- Thermoplastic Prepreg Growth: Thermoplastic prepregs are witnessing increasing demand due to their recyclability, faster processing, and suitability for mass production.

- Automation and Out-of-Autoclave Processing: New manufacturing processes such as automated tape laying and out-of-autoclave curing are improving efficiency and lowering production costs.

- Sustainability and Recycling: The industry is moving toward bio-based resins and recyclable prepregs to align with global sustainability goals.

- Regional Expansion: Asia-Pacific, led by China and India, is emerging as a high-potential market driven by aerospace investments, wind energy projects, and growing automotive production.

- Mergers and Collaborations: Strategic partnerships among composite manufacturers, resin developers, and OEMs are driving innovation and expanding supply chain resilience.

Conclusion

The prepreg market stands at the forefront of modern engineering, driven by the global need for lightweight, durable, and high-performance materials. With increasing applications across aerospace, automotive, wind energy, and beyond, prepregs are poised for accelerated growth. Future innovations in thermoplastic prepregs, sustainable materials, and manufacturing efficiency will only strengthen their role as the backbone of advanced composites.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology