PTFE vs. Graphite Gaskets: Choosing the Right Sealing Solution for Industrial Applications

PTFE vs. Graphite Gaskets: Choosing the Right Sealing Solution for Industrial Applications

In modern industry, sealing components are far more than simple accessories—they are essential for system safety, operational efficiency, and environmental protection. From oil and gas pipelines to chemical reactors, pharmaceutical production, power plants, and machinery manufacturing, reliable seals prevent leaks, maintain pressure, and reduce risks.

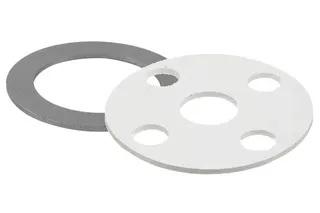

Among the wide variety of sealing materials, PTFE gaskets and graphite gaskets are two of the most widely used. Each offers unique strengths suited to specific applications. This article explores their characteristics, advantages, applications, and selection guidelines to help you make informed decisions.

PTFE Gaskets: Features and Benefits

PTFE (Polytetrafluoroethylene), also known as Teflon, is a high-performance plastic widely recognized for its chemical inertness and physical reliability. PTFE gaskets are typically machined from rods, sheets, or tubes to precise dimensions to ensure tight sealing.

Key Advantages of PTFE Gaskets:

-

Exceptional Chemical Resistance

-

Resistant to almost all chemicals, including strong acids (sulfuric, nitric) and bases (sodium hydroxide).

-

Ideal for chemical processing, pharmaceuticals, and other aggressive environments.

-

-

Stable Physical Performance

-

Operates reliably from -196°C to +250°C.

-

Maintains elasticity and toughness under temperature fluctuations or vibration.

-

-

Non-Stick Surface

-

Low surface energy prevents adhesion of contaminants.

-

Simplifies cleaning, replacement, and reduces risk of product contamination, making it ideal for food, medical, and pharmaceutical industries.

-

-

Reliable Sealing Capability

-

Adjustable density and hardness allow adaptation to varying flange surfaces.

-

Elasticity and compression recovery provide self-tightening, multi-layered sealing.

-

-

Wide Media Compatibility

-

Handles water, oil, acids, alkalis, and most solvents.

-

Non-toxic and biologically inert, suitable even for medical or food-grade applications.

-

Key Quality Considerations for PTFE Gaskets:

-

Thickness Tolerance: Critical due to PTFE's “cold flow” under sustained pressure.

-

Material Purity: Dispersion-resin PTFE offers superior performance over recycled or blended materials.

-

Manufacturing Precision: CNC machining enhances dimensional accuracy and sealing reliability.

Graphite Gaskets: Features and Benefits

Graphite gaskets are typically punched or cut from sheets of high-carbon natural flake graphite, sometimes reinforced with materials like stainless steel mesh to improve mechanical strength.

Key Advantages of Graphite Gaskets:

-

High-Temperature Resistance

-

Can withstand temperatures up to 1000°C or more, depending on reinforcement.

-

Common in power plants, steel manufacturing, and petrochemical industries.

-

-

Strong Chemical Resistance

-

Resistant to most acids, alkalis, and organic solvents.

-

Effective in aggressive chemical environments similar to PTFE.

-

-

Flexibility and Compressibility

-

Naturally soft and adaptable, filling gaps in rough or warped flanges.

-

Maintains sealing performance under fluctuating operational conditions.

-

-

Good Thermal Conductivity

-

Conducts heat well, reducing thermal stress and preventing localized overheating.

-

-

Cost-Effective and Accessible

-

Mature production process and widely available raw materials.

-

Offers reliable performance at lower cost compared to PTFE.

-

Key Quality Considerations for Graphite Gaskets:

-

Raw Material Quality: High-carbon, refined graphite ensures durability and chemical resistance.

-

Reinforcements: Stainless steel or foil enhancements improve strength under high pressure.

-

Dimensional Precision: Accurate cutting and clean edges are essential for reliable sealing.

PTFE vs. Graphite: Side-by-Side Comparison

| Feature | PTFE Gasket | Graphite Gasket |

|---|---|---|

| Chemical Resistance | Excellent; nearly all chemicals | Excellent; acids, alkalis, solvents |

| Temperature Range | -196°C to +250°C | Up to 1000°C (with reinforcement) |

| Flexibility | Highly flexible; self-adjusting | Flexible; fills gaps well |

| Thermal Conductivity | Poor conductor | Good conductor |

| Non-Stick | Very low adhesion; easy to clean | Slight adhesion; less suitable for ultra-clean applications |

| Mechanical Strength | Lower under high pressure | High with reinforcement |

| Cost | Generally higher | More cost-effective |

| Use in Clean Environments | Excellent (food, medical) | Less ideal for ultra-clean settings |

How to Choose Between PTFE and Graphite Gaskets

Consider the following factors:

-

Temperature:

-

PTFE: -196°C to 250°C

-

Graphite: Ideal for high-temperature applications up to 1000°C

-

-

Chemical Aggressiveness:

-

PTFE: Best for highly corrosive or ultra-pure fluids

-

Graphite: Excellent for acids, alkalis, and solvents

-

-

Cleanliness Requirements:

-

PTFE: Ideal for sanitary environments (food, pharma, electronics)

-

Graphite: Suitable for industrial but not ultra-clean environments

-

-

Pressure and Mechanical Load:

-

Reinforced graphite handles extreme pressure and heat well

-

PTFE suitable for moderate pressure and chemical systems

-

-

Maintenance and Handling:

-

PTFE: Easy to remove and replace

-

Graphite: Durable, but may be slightly harder to handle in clean environments

-

-

Cost Considerations:

-

Graphite: Generally more economical for industrial applications

-

PTFE: Higher cost but superior chemical resistance and hygiene

-

Conclusion

Both PTFE and graphite gaskets are high-performance sealing solutions with unique advantages. PTFE excels in chemical resistance, flexibility, and ultra-clean applications, while graphite provides high-temperature resilience, mechanical strength, and cost efficiency.

Selecting the right gasket depends on understanding your system’s temperature, pressure, chemical exposure, cleanliness requirements, and budget. By choosing the appropriate material, you can ensure reliable sealing, protect equipment, and maintain operational efficiency across diverse industrial environments.

Whether maintaining a chemical plant, a power generation system, or a food processing line, the right gasket choice makes all the difference.

It's important to know about Google SEO to help your website rank higher in search results.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology