Aluminum circle 1060 h16 is softer than 1060 h18 and much harder than 1060-O, applied to cookware, lamp covers and battery shells. The circle is a 1xxx aluminium alloy, containing 99.6% content of aluminum and featured by low hardness, good corrosion resistance, satisfying elongation, excellent heat conductivity and cheap price.

Regular thickness of 1060 aluminium circle h16 ranges from 0.1mm to 6mm. Some suppliers offer up to 10mm. The thickness of the aluminum circles is not necessarily related to the rolling technology. Not all thin aluminum wafers are cold-rolled. Hot-rolled aluminum coils can also be stopped by cold-rolling equipment to become further hot-rolled thin aluminum wafers. However, the required ingots with a thickness of more than 8mm are produced after hot rolling after processing, which will produce losses and are different from consumer equipment. The quotation of equipment is relatively high, so the price bias of aluminum wafers is ultimately due to the hot rolling machine The price of ultra-thick round aluminum in the production range is high.

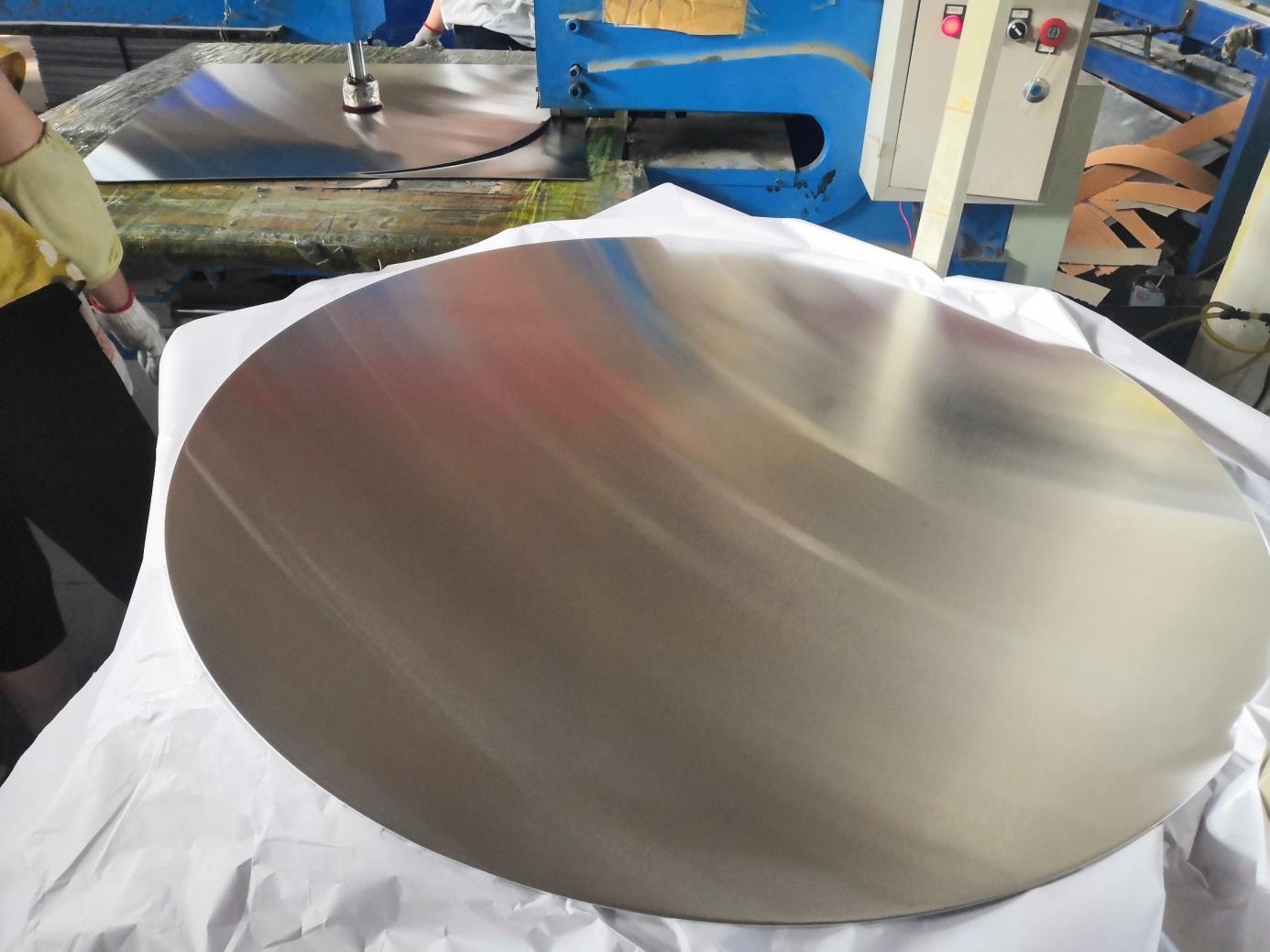

1060 h16 aluminium circle discs are made into non-stick cookers, higher pressure cookers, hardware parts, lamp covers, thermos shells and so on. Suitable for both spinning and deep drawing, the discs can also be of tempers O, H12, H14, H18, H22, H24, H26 etc. Common diameters cover 200mm to 950mm.

Aluminum circle 1060 h16 from 20-year manufacturer