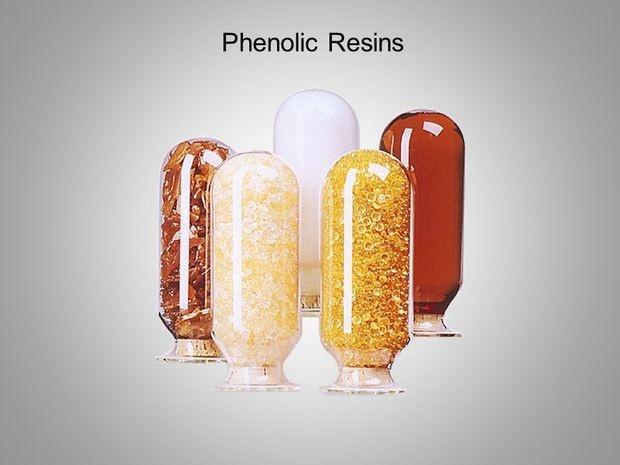

Phenolic resins, also known as phenol–formaldehyde resins, are synthetic polymers that are produced from the reaction of phenol or substituted phenol with formaldehyde. They are commonly used as thermosetting plastics and can be molded into a variety of products. Phenolic resins are primarily used in manufacturing of items like furniture components, automotive components, electrical insulator parts, flooring, kitchen countertops, and laminates. They provide properties like fire resistance, stiffness, adhesion, abrasion resistance, and stain resistance in the final products.

The global Phenolic Resins Market is estimated to be valued at Us$ 16052.98 Mn in 2023 and is expected to exhibit a CAGR Of 5.9% over the forecast period 2023 To 2030, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

Rising application in various end-use industries is estimated to be a major driver for the phenolic resins market over the forecast period. Phenolic resins are extensively used in manufacturing of items like furniture, laminates, adhesives, coatings, automotive components, and electrical equipment. Growing construction and automotive industries globally has led to an increase in demand for phenolic resins. According to India Brand Equity Foundation (IBEF), the Indian construction industry's current market size is expected to reach US$ 1.4 trillion by 2025. The flourishing construction sector has fueled the growth in furniture and laminates industry, thereby propelling phenolic resins market. Another driver for the market is their diverse physical and chemical properties like high heat resistance, adhesion and ability to bond with metals and other substrates, owing to which they are preferred material for high performance applications like circuit boards and automobile engine components. However, emission of formaldehyde during resins production and toxic nature of phenol may slightly hamper industry growth.

SWOT Analysis for Phenolic Resins Market

Strength: Phenolic resins offer excellent resistance to heat, water, and corrosion making them ideal for insulation applications. Phenolic resins also exhibit high electrical resistance and thermal stability which makes them suitable for use in electrical equipment. Their ability to be molded into complex shapes allows for versatile applications.

Weakness: Phenolic resins emit toxic fumes when heated, which can cause health issues for workers during production. Strict environmental regulations around the world restrict the use of formaldehyde in several applications. The production of phenolic resins also involves the use of toxins like formaldehyde.

Opportunity: Growing demand for lightweight composites from industries like automotive and aerospace offers potential growth opportunities. Phenolic resins can be used to manufacture durable and lightweight composites suitable for these industries. Increasing spends on infrastructure development will boost demand for construction materials where phenolic resins have applications.

Threats: Strict environmental regulations around the world limit the use of toxic chemicals used in phenolic resin production. Alternative eco-friendly resin technologies pose a threat. Volatility in raw material prices also affects market competitiveness.

Key Takeaways

The Global Phenolic Resins Market Demand is expected to witness high growth.

Regional analysis:

The Asia Pacific region accounts for the largest share of over 40% of the global phenolic resins market. Swift urbanization and industrialization in China and India has fueled growth of end-use industries. Growing construction and automotive sectors benefit the phenolic resins market. Countries like China, Japan, and India are major consumers and producers of phenolic resins.

Key players:

Key players operating in the phenolic resins market are ABB Ltd, Schneider Electric SE, Siemens AG, and Eaton Corporation plc. ABB Ltd is a leading player providing solutions for power grids, electrification, automation and robotics.

Get more insights on this topic :

Check more trending articles on this topic: