Industrial Burner Market is Estimated to Witness High Growth Owing to Opportunity in Energy Efficient Products

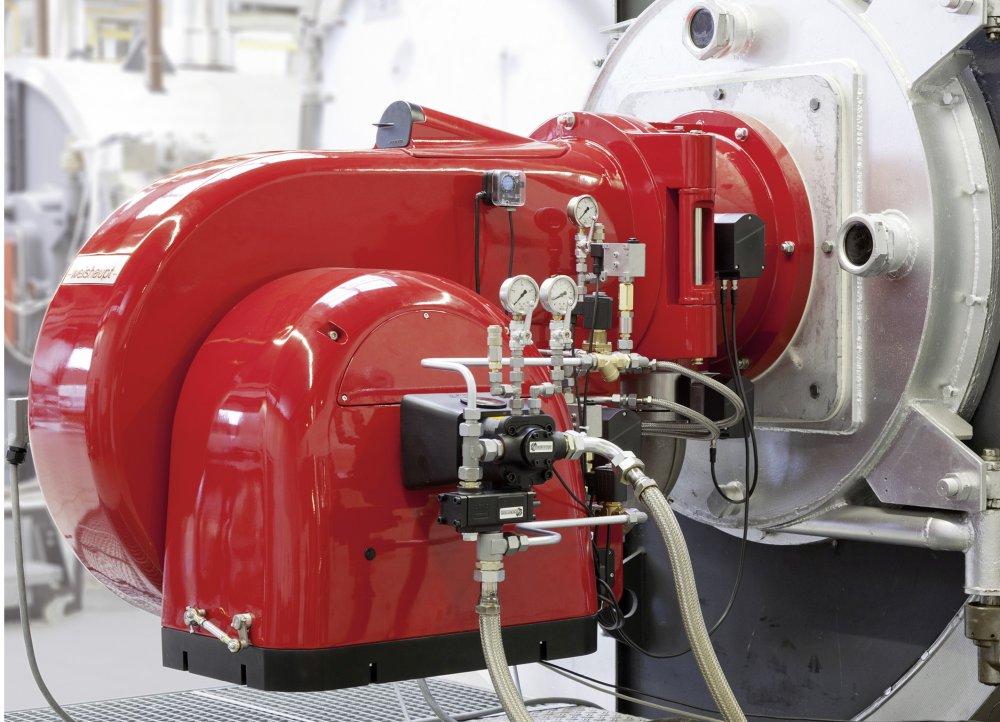

Industrial burners are fuel burning devices used in variety of industrial applications such as forging, heating, drying and heating processes. They are designed to burn various types of fuels including natural gas, light fuel oil, kerosene and propane efficiently and completely. Industrial burners offer several advantages such as high combustion efficiency, minimal heat loss and uniform temperature distribution. They are used across industries like food, chemical, metal, oil and gas, pulp and paper, mining and others.

The global Industrial Burner Market is estimated to be valued at US$ 5.2 billion in 2023 and is expected to exhibit a CAGR of 5.5% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market Opportunity:

Energy Efficient Products

With growing focus on energy conservation and reducing carbon footprint, there exists significant opportunity for industrial burners offering high energy efficiency. Industrial burners integrated with advanced controls, sensors and design can significantly curb energy wastage and optimize fuel usage. Manufacturers focusing on developing burners with programmable logic controllers, variable speed fans, oxy-fuel technology and auto combustion balancing are well positioned to tap into the market demand for energy efficient products. governments across regions are also encouraging adoption of energy efficient burners through fiscal incentives and regulations, thereby driving their market growth.

Porter's Analysis

Threat of new entrants: The industrial burner market has moderate threat of new entrants as significant capital investment is required to build manufacturing facilities, obtain technical certifications, and establish a distribution network.

Bargaining power of buyers: Buyers have moderate bargaining power as there are numerous industrial burner manufacturers they can negotiate with for procurement. However, high fuel efficiency, safety, and emissions standards compliance are critical factors.

Bargaining power of suppliers: A few large multinational corporations supply critical burner components like valves, control units, and burners. This gives them significant bargaining power over burner manufacturers.

Threat of new substitutes: Threat from substitutes is low as burners have specific combustion and emission requirements for various industrial processes which cannot be easily replaced.

Competitive rivalry: The market has high competition among global players like Alzeta Corporation, Andritz, Baltur, Bloom Engineering, and Forbes Marshall. They compete on product quality, fuel flexibility, and after-sales support.

SWOT Analysis

Strengths: Industrial burners offer fuel flexibility, high combustion efficiency, and comply with stringent emissions norms. Leading brands have extensive distribution networks and industry expertise.

Weaknesses: Burner projects require long lead times and unplanned downtime can be expensive for process plants. Smaller players have limited production capacities and geographical footprints.

Opportunities: Growing demand from cement, petrochemical and steel industries especially in Asia Pacific and Middle East regions provide major opportunities. Development of IoT-enabled burners can boost remote monitoring and servicing.

Threats: Fluctuating fuel prices and raw material costs remain major threats. Stringent environmental policies in developed markets increase compliance costs.

Key Takeaways

The Global Industrial Burner Market Size is expected to witness high growth over the forecast period of 2023 to 2030.

Regional analysis: Asia Pacific region is projected to grow at the highest CAGR during the forecast period led by rapidly expanding manufacturing sector in countries like China, India and ASEAN nations. Strict emissions regulations and growing emphasis on industrial energy efficiency will further aid the regional market.

Key players operating in the industrial burner market are Alzeta Corporation, Andritz, Baltur, Bloom Engineering, Forbes Marshall, Foster Wheeler, and Honeywell International Inc. These leading burner manufacturers offer differentiated products and solutions to process diverse fuel types effectively while complying with emissions norms.

Get more insights on this topic:

https://www.marketwebjournal.com/industrial-burner-market-insights/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology