Reflective aluminum sheets are a type of metal sheet that have been specially treated to reflect light efficiently, giving them a shiny, mirror-like appearance. They are used in various applications due to their high reflectivity and other beneficial properties.

Manufacturing Process

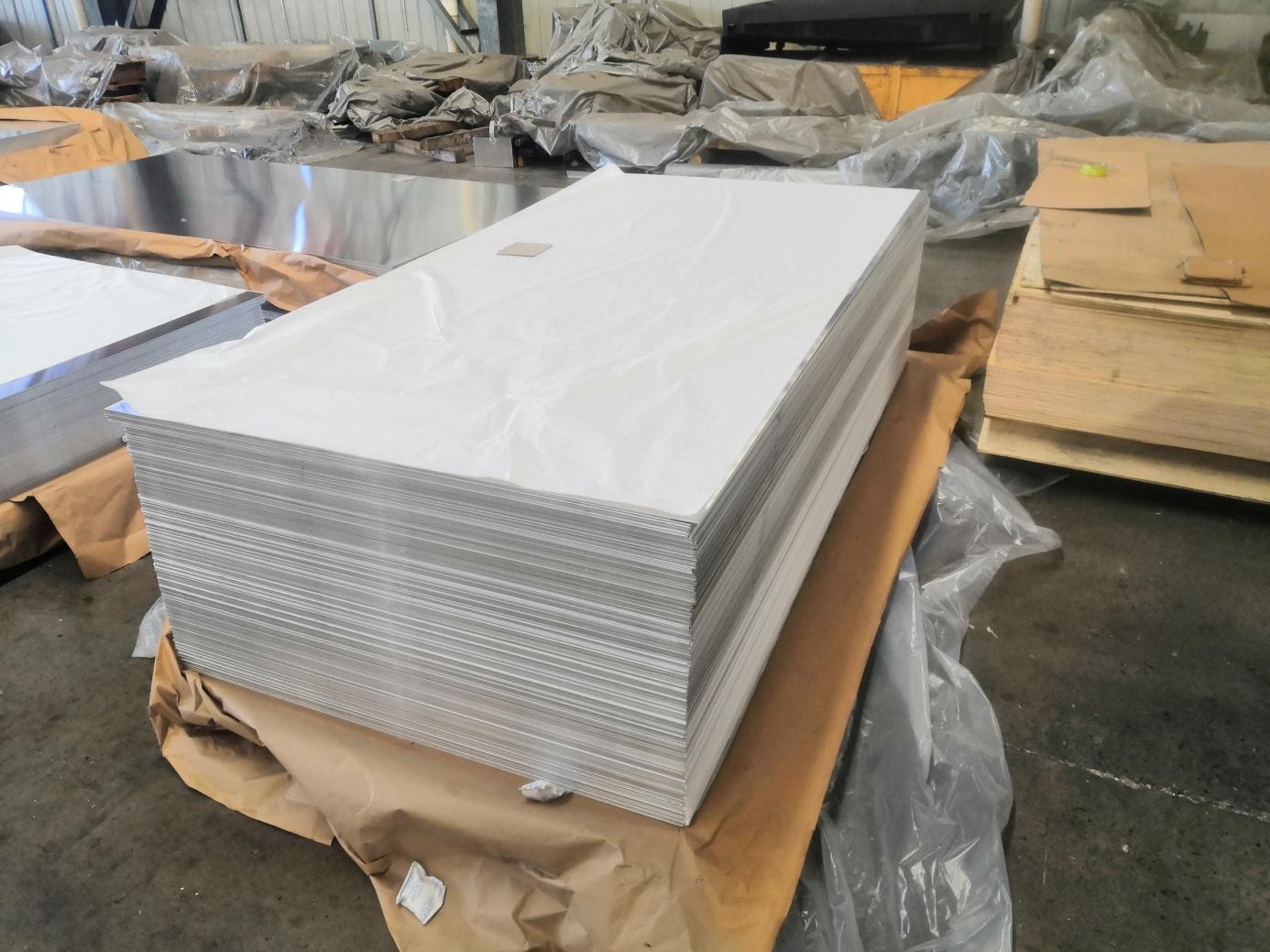

Reflective aluminum sheets are created using several different techniques, including polishing, anodizing, chemical etching, and coating with a reflective film. The surface of the aluminum plate is treated by rolling, grinding, and other methods to achieve a mirror effect.

Properties and Applications

Reflective aluminum sheets are known for their high degree of reflectivity, which can reach over 96%, even up to 98%. They are much thinner and lighter than traditional options, making them easier to fabricate and mount. Moreover, they are virtually unbreakable, making them suitable for many applications where a heavy, breakable reflector would be a liability.

Reflective aluminum sheets are perfect for any application where high reflectivity is required for the beauty or function of the project, but where the weight, inflexibility, fabrication difficulty, or breakability of other reflective materials would be a problem. They are used in optical lighting, electronics, automotive, aviation, and medical applications.

One of the leading-edge reflective surfaces in the world is Anolux-MIRO-SILVER®, with an unmatched minimum total reflectivity (TR) of 98%. This product offers both performance reliability and design versatility.

Advantages

Reflective aluminum sheets are supplied in 4 x 8-foot panels that are 2mm thick and weigh under 20 pounds each. They can be fabricated using ordinary woodworking tools and can be bent to conform to columns or other curved surfaces. Because they’re lightweight and shatterproof, they can be mounted to walls with double-sided VHB tape, a soft mastic such as construction sealant, or simple mechanical fasteners.

Reflective aluminum sheets are ideal for reflecting a unique architectural brilliance in interior cladding, sculptural installations, and other special projects. They are also perfect for locations such as aircraft lavatories, gyms and spas, prisons, retail security, and many other applications where a heavy, breakable reflective material can’t be safely used.

In conclusion, reflective aluminum sheets are a versatile and innovative material with a wide range of applications due to their unique properties. They offer a high degree of reflectivity, ease of fabrication, and durability, making them an excellent choice for various industries.

Reflective Aluminum Sheet: An Overview