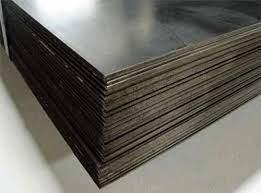

Understanding MS Plates: Properties, Applications, and Market Trends

Mild Steel (MS) plates, otherwise called plain carbon steel plates, are basic parts in different modern sectors because of their flexible properties and boundless applications. In this article, we dive into the attributes, uses, and market trends of MS plates.

Properties of MS Plates

MS plates are described by their low carbon content, regularly going from 0.05% to 0.25%, making them moderately flexible and simple to weld. They have moderate strength and show great formability, considering simple molding and creation into various primary parts. Moreover, MS plates have fantastic machinability, empowering them to be promptly handled utilizing customary machining procedures.

The microstructure of MS plates comprises ferrite and pearlite stages, adding to their mechanical properties. While MS plates miss the mark on high strength of alloyed steels, they are reasonable for a wide cluster of applications that don't need outrageous strength or particular properties.

Applications of MS Plates

MS plates track down broad use across different industries because of their flexibility and cost-viability. A few normal applications include:

-

Construction: MS plates are broadly utilized in the construction business for manufacturing primary parts like beams, columns, and girders. They provide the necessary strength and durability for building frameworks, bridges, and infrastructure projects.

-

Automotive: In the automotive sector, MS plates are used in the manufacturing of vehicle frame, body boards, and underlying reinforcements. Their formability and weldability make them appropriate for creating different automotive parts.

-

Shipbuilding: MS plates are fundamental in shipbuilding, where they are utilized in the construction of bodies, decks, bulkheads, and other marine designs. The erosion opposition of MS plates can be upgraded through surface coatings or defensive measures.

-

Hardware and Gear: MS plates act as base materials for creating apparatus parts, hardware lodgings, and modern tools. Their machinability and weldability make them ideal for delivering an extensive variety of hardware and gear.

-

Storage Tanks and Tension Vessels: MS plates are used in the creation of storage tanks, pressure vessels, and funneling systems for storing and shipping fluids and gases in different modern applications.

Market Trends in MS Plates

The market for MS plates is impacted by a few factors, including modern demand, raw material costs, regulatory strategies, and mechanical headways. A few outstanding trends molding the MS plates market include:

-

Demand-Supply Dynamics: The demand for MS plates is firmly connected to modern exercises, infrastructure improvement, and construction projects. Vacillations in global economic circumstances and infrastructure ventures influence the demand for MS plates.

-

Raw Material Costs: The expense of raw materials, basically iron mineral and salvaged material, altogether impacts the evaluating of MS plates. Variances in raw material prices, driven by supply-demand dynamics and market hypothesis, influence the general creation costs of MS plates.

-

Mechanical Headways: Advances in steel manufacturing advances, including further developed refining processes, moving procedures, and surface treatment strategies, improve the quality and performance of MS plates. Innovative advancements additionally add to the improvement of high-strength MS plates with upgraded mechanical properties.

-

Ecological Guidelines: Rigid natural guidelines with respect to discharges decrease and manageability drive the reception of cleaner creation processes in the steel business. Makers of MS plates are progressively zeroing in on natural manageability by carrying out energy-productive practices and decreasing carbon impressions.

-

Market Contest: The MS plates market is described by extraordinary rivalry among makers, both provincially and globally. Organizations endeavor to separate themselves through item quality, development, and worth added administrations to acquire an upper hand on the lookout.

Conclusion

MS plates are vital materials in different modern sectors, attributable to their adaptable properties and colossal applications. With their moderate strength, magnificent formability, and cost-viability, MS plates assume an essential part in construction, automotive, shipbuilding, hardware, and other industries.

As the global economy keeps on advancing, the demand for MS plates is supposed to stay hearty, driven by infrastructure improvement, modern extension, and innovative headways. Producers and partners in the MS plates market should adjust to changing business sector dynamics, mechanical developments, and regulatory necessities to support development and stay cutthroat in the business.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology