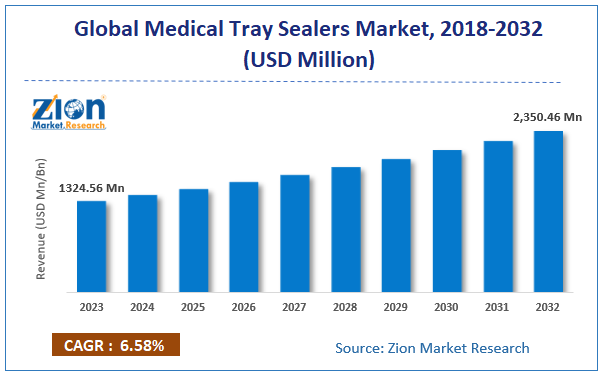

The medical tray sealers market focuses on equipment used to seal trays that contain sterile medical devices, surgical instruments, and other healthcare products. These sealers are crucial in maintaining the sterility of medical products until they are used, ensuring safety and reducing the risk of contamination. The market has seen growth due to the increasing demand for sterile packaging in the medical industry, advancements in packaging technology, and stringent regulatory requirements for medical device packaging.

Key Market Insights

-

Market Growth Drivers:

- Growing Demand for Sterile Medical Packaging: The increasing need for sterilized medical products, driven by the rising number of surgeries and healthcare procedures, is a significant driver of the medical tray sealers market.

- Regulatory Compliance: Stringent regulations regarding the packaging of medical devices and products are pushing healthcare facilities and manufacturers to adopt high-quality sealing solutions.

- Advancements in Packaging Technology: Technological advancements, including automation and integration of digital monitoring systems in medical tray sealers, are enhancing efficiency and reliability, fueling market growth.

- Rising Focus on Infection Control: With the global emphasis on infection control, particularly in the wake of the COVID-19 pandemic, the importance of maintaining sterility in medical packaging has become even more critical.

-

Market Segmentation:

- By Product Type:

- Automatic Tray Sealers: Fully automated systems that offer high efficiency and are used in large-scale production environments.

- Semi-Automatic Tray Sealers: Systems that require some level of manual intervention, suitable for medium-scale operations.

- Manual Tray Sealers: Basic sealers that are manually operated, typically used in smaller facilities or for low-volume applications.

- By End-User:

- Hospitals: Use tray sealers for sterilizing and packaging instruments and supplies.

- Ambulatory Surgical Centers (ASCs): Growing in importance as more outpatient procedures are performed.

- Medical Device Manufacturers: The largest segment, as these sealers are integral to the packaging processes for sterile medical devices.

- Pharmaceutical Companies: Utilize tray sealers for packaging drug delivery systems and other sterile products.

- By Material Compatibility:

- Plastic: The most common material sealed, used widely in medical device trays.

- Aluminum: Used for certain types of medical packaging requiring barrier properties.

- Others: Includes paper and other specialized materials used in medical packaging.

- By Product Type:

-

Geographical Insights:

- North America: Dominates the market due to advanced healthcare infrastructure, high healthcare expenditure, and strict regulatory standards for medical packaging.

- Europe: A strong market driven by a robust healthcare system, stringent regulations, and a significant number of medical device manufacturers.

- Asia-Pacific: Expected to experience significant growth due to increasing healthcare investments, expanding medical device manufacturing, and improving healthcare infrastructure.

- Latin America and Middle East & Africa: Emerging markets with growing healthcare needs and increasing focus on improving healthcare quality and safety standards.

-

Challenges:

- High Initial Investment: The cost of acquiring advanced medical tray sealers, particularly automated systems, can be high, posing a challenge for smaller healthcare facilities and manufacturers.

- Maintenance and Operational Costs: Ongoing maintenance, calibration, and operational costs can add to the overall expense, affecting market adoption in cost-sensitive regions.

- Technical Expertise: The need for trained personnel to operate and maintain advanced sealing equipment can be a barrier, particularly in regions with a shortage of skilled healthcare workers.

-

Competitive Landscape:

- Key Players: Major companies in the market include MULTIVAC, Atlas Vac Machine, Amcor, DuPont, and Nelipak Healthcare Packaging. These companies focus on product innovation, expanding their product offerings, and providing comprehensive customer support.

- Product Innovation: There is a strong emphasis on developing sealers with enhanced features such as real-time monitoring, automated adjustments, and compatibility with a wider range of materials.

Future Trends

- Automation and Industry 4.0: The trend towards automation and the integration of Industry 4.0 technologies, such as IoT and data analytics, is expected to continue, leading to smarter and more efficient sealing systems.

- Sustainable Packaging Solutions: The growing focus on sustainability is likely to drive demand for sealers that can work with eco-friendly materials and reduce waste.

- Customization and Flexibility: The market is expected to see an increasing demand for customizable sealing solutions that can accommodate different tray sizes, materials, and packaging needs.

- Integration with Sterilization Processes: The integration of tray sealing with sterilization processes will become more prevalent, allowing for more seamless and efficient packaging workflows.

The medical tray sealers market is poised for continued growth as the demand for sterile medical packaging increases, driven by the rising number of surgeries, the need for infection control, and advancements in medical device manufacturing. As the industry evolves, there will be a greater emphasis on automation, sustainability, and the ability to meet diverse packaging requirements.

Contact :

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com