Piperylene Supply-Demand, Growth, End User Analysis, Raw Materials and Outlook

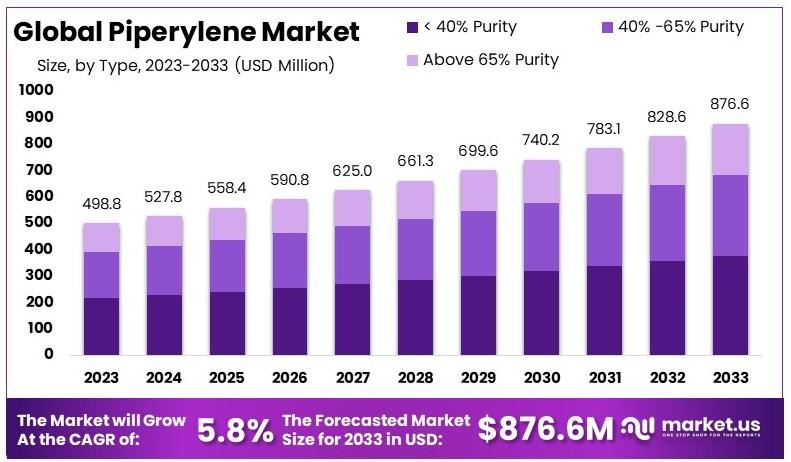

The Global Piperylene Market size is expected to be worth around USD 876.6 Million by 2033, from USD 498.8 Million in 2023, growing at a CAGR of 5.8% during the forecast period from 2024 to 2033.

Piperylene, also known as 1,3-pentadiene, is a colorless, highly flammable hydrocarbon with the chemical formula C5H8. It is a byproduct of the thermal cracking of naphtha and other hydrocarbons during the production of ethylene and propylene. Piperylene is primarily used as a key monomer in the production of various synthetic rubbers, adhesives, resins, and coatings. Its reactivity and ability to polymerize make it a valuable component in manufacturing products that require elasticity, durability, and chemical resistance. The demand for piperylene is driven by its applications in the automotive, construction, and packaging industries, where it plays a crucial role in enhancing material performance.

Market Key Players:

-

Sinopec

-

Formosa Chemical

-

Zeon

-

LOTTE Chemical

-

Eastman

-

LyondellBasell

-

Mitsui

-

Shell

-

Ningbo Jinhai Chenguang Chemical

-

Braskem

-

Shandong Yuhuang Chemical

-

YNCC

-

Nanjing Yuangang

Click here for request a sample : https://market.us/report/piperylene-market/request-sample/

Purity Analysis:

The Piperylene Market is segmented by purity levels, with the <40% purity segment dominating at 43.9% due to its cost-effectiveness and sufficient performance in adhesives and sealants. Above 65% purity piperylene, used in high-performance applications like advanced adhesives and specialty chemicals, is growing due to rising demand in automotive and packaging industries. The 40%-65% purity segment serves as a balance between cost and performance, catering to industries that require moderate quality at reasonable costs, ensuring comprehensive market coverage.

Application Analysis:

The adhesives segment leads the Piperylene Market with a 45.9% share, driven by demand in packaging, automotive, and construction industries, particularly in pressure-sensitive adhesives. The rubber segment, essential for synthetic rubbers used in tire manufacturing, is also significant, influenced by the growing global automotive industry. Additionally, piperylene is used in paints and coatings to enhance adhesion and durability, serving specific high-performance applications in construction and industrial maintenance.

Key Market Segments:

By Purity

-

< 40% Purity

-

40% – 65% Purity

-

Above 65% Purity

By Application

-

Adhesives

-

Paints

-

Rubber

-

Others

Driving Factors:

The piperylene market is driven by the expanding adhesives and sealants industry, where piperylene is crucial in producing tackifying resins for pressure-sensitive adhesives (PSAs). The surge in e-commerce, packaging, and automotive industries, particularly with companies like Amazon, has significantly boosted demand. Additionally, growth in rubber and tire manufacturing, fueled by the automotive industry's expansion, and the increasing production of plastics for medical and packaging applications further drive market growth.

Restraining Factors:

The market faces challenges from volatile raw material prices, with fluctuations in crude oil and natural gas impacting piperylene costs and deterring long-term contracts. Environmental regulations and sustainability concerns also restrain growth, as stricter norms on VOC emissions and the shift towards bio-based alternatives reduce piperylene's use in adhesives, coatings, and other applications.

Growth Opportunities:

Advances in medical plastics offer significant growth opportunities for piperylene, particularly in producing COC and COP resins used in medical devices and diagnostics. The rise of electric vehicles (EVs) also presents an opportunity, as the demand for lightweight materials and advanced synthetic rubbers grows with the global shift towards EVs.

Trending Factors:

The development of bio-based piperylene from renewable sources, like biomass, is a growing trend, aligning with sustainability goals and enhancing market prospects. Additionally, the increasing adoption of smart packaging, which utilizes piperylene-based adhesives in RFID tags and temperature indicators, is driving demand in the packaging industry, supported by IoT and consumer engagement trends.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology