Resin has multiple chemical, mechanical and thermal properties, and these properties are found in all kinds of resins. However, epoxy resin in Sydney is a standard above all other types, and it is a synthesised resin that can be useful in numerous industrial applications. They offer better chemical, mechanical, and thermal properties, and are highly versatile and are incredible adhesive materials. It is mainly used globally in the manufacturing, woodwork, and construction industries for numerous reasons. For example, it has excellent adhesive strength and better resistance to moisture and chemicals.

It can also bear moderate temperatures, and these reasons make epoxy resin in Sydney a top choice in the construction industry. In most cases, it is used as a solid waterproofing barrier, which is capable of resisting high temperatures. There are numerous other benefits, and we have come up with this post where you will learn everything about epoxy resin in Sydney including types, uses, properties, chemical composition, etc.

WHAT IS AN EPOXY RESIN IN SYDNEY?

Epoxy resin is a two-part synthetic polymer material, which is prepared by mixing two parts in a 4:2 to 1:2 in resin to hardener ratio. When this composition is ready, a chemical reaction starts, and the outcome is a strong and durable adhesive solution known as epoxy resin. As mentioned above, epoxy resins are highly adhesive and can be used in various applications and industries. They are highly practical both commercially and domestically, and in most cases, they are used in construction and manufacturing industries, such as electric circuit boards, fibre optics, etc.

WHAT IS EPOXY RESIN IN SYDNEY MADE OF?

Epoxy resins are broadly categorised into two main categories: glycidal and non-glycidal. The glycidal epoxy resins are further classified into Glycidal Esters, Glycidal Ethers and Glycidal Amines. Aliphatic and cyclo-aliphatic resins fall in the category of non-glycidal resins. Let us quickly go through some safe handling tips for all epoxy resins.

Epoxy Resin In Sydney – Safe Handling Tips

Epoxy resins are used in the construction industry mainly for constructing epoxy resin floorings in Sydney or manufactured to be completely safe and harmless. However, it is still recommended that those working with this material follow essential safety precautions. For example, they must protect their hands against exposure to resin and hardening liquids.

They can do this easily by wearing industrial-grade safety gloves, and nitrile gloves are recommended the most, as they don't react when encountering resins. Baby wipes can be used to remove any resin from your skin, and soap and water can also be used.

Skin protection is necessary, and you can ensure this by wearing a good quality apron while handling epoxy resin in Sydney. Safety goggles are also recommended, and you need to flush your eyes thoroughly multiple times if resin accidentally touches your eyes. In this situation, rubbing your eyes while washing is not recommended, as it will spread the resin further. Don't delay getting medical attention at all.

Another recommendation is that the area should be adequately ventilated while working with epoxy resin floorings in Sydney. This means doors and windows should be open, and no one other than workers should be allowed in the area. Ceiling fans and exhaust fans should also be switched 'on' to eliminate fumes immediately. Respiratory masks should also be on standby if fumes make anyone uncomfortable or exhausted.

USES OF EPOXY RESIN IN SYDNEY

As mentioned above, the epoxy resin in Sydney can be used for various purposes like adhesion, coating, and forming composite materials, including fibreglass reinforcement, carbon fibre and much more. The properties of epoxy resin can be modified for use in other causes as well. Let us get a quick idea of the most common uses of epoxy resin in Sydney.

EPOXY RESIN AS ADHESIVES

Epoxy resin in Sydney can be used as an engineering adhesive or structural adhesive. They are available in different chemical varieties, including cyanoacrylate, acrylic polyurethane, and more. In most cases, it is used to bond snowboards, golf clubs, skis and parts of aircraft. It provides excellent bonding to materials, including glass, stone, metal, wood and several others. However, it loses its adhesion capabilities when the temperature rises above 177 degrees Celsius.

INDUSTRIAL USES OF EPOXY RESIN IN SYDNEY

Epoxy resin in Sydney is used in factories and industries as a strong adhesive to produce industrial tools and create fixtures, castings, laminates, master models, and moulds. This resin's water resistance makes it an incredible component in several industrial applications.

EPOXY RESIN IN SYDNEY'S CONSTRUCTION INDUSTRY

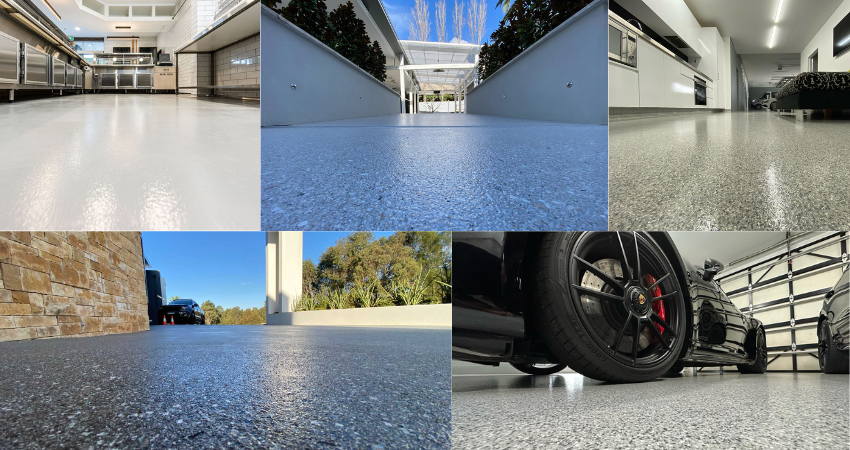

This resin is used in the construction industry due to its exceptional durability, moisture and chemical resistance. The substantial adhesion property is the common reason this resin is used in multiple industries. For example, it is used for repairing concrete structures and also as epoxy resin floorings in Sydney. Builders also rely upon epoxy resin to restore the building's integrity and fill cracks in floors, walls, and other surfaces. It is a durable and seamless flooring solution used in industrial and commercial structures.

Particularly in the construction industry, epoxy is known for providing a smooth surface that is fully resistant to issues like impacts, abrasions, and chemicals. It is also used for grouting applications and as bonding agents, where strong adhesion is required.

COMPARING EPOXY RESIN IN SYDNEY WITH OTHER RESINS

We have assessed the versatility of epoxy resin in Sydney, so let us compare it with other popular resins available. We will first go with casting resin.

WHAT IS CASTING RESIN?

Casting resin is also epoxy resin manufactured for moulding and casting. It has low viscosity, and this is why it is more in liquid form and takes longer to cure. The benefit is that the flow is very easy, and the mould can be filled very smoothly and effortlessly to give any shape.

WHAT IS ACRYLIC RESIN?

Polymethyl methacrylate, or PMMA is also known as acrylic resin, and it is a thermoplastic material used as a liquid monomer. It polymerises completely when exposed to light or heat, and it features incredible stability against ultraviolet rays. It is also completely impact-resistant, and this is why it is used in manufacturing decorative items and prosthetics for dentists.

WHAT IS POLYESTER RESIN?

Polyester resin is a thermosetting polymer that has to be mixed with a hardener or catalyst. It has excellent chemical resistance and incredible mechanical strength, and it is most commonly used in fibreglass reinforcement applications. Polyester resin is also used to build composite structures, automotive parts, and boats.