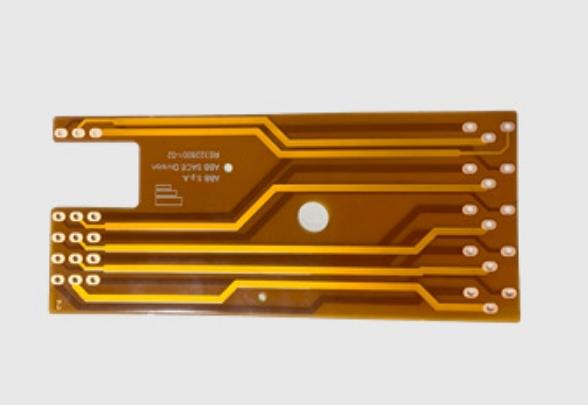

Flexible Printed Circuit (FPC) is commonly referred to as a soft board or flexible circuit board. FFC cables, also known as flexible flat cables, allow the user to freely choose the number of wires and spacing, making connections more convenient. These cables significantly reduce the size of electronic products, lower production costs, and improve manufacturing efficiency, making them ideal for connecting two related parts or products. Nowadays, many products utilize FFC cables due to their flexibility, and they have been widely adopted in products such as printers, mobile phones, and laptops. This article focuses on how to quickly solder FPC cables to solder pads on a PCB (Printed Circuit Board). Below,Gekun PCB will explain the process in detail.

How to Solder FPC Cables to a PCB?

1. Manual Soldering with an Electric Soldering Iron

When manually soldering, it is best to place a heavy object on the flexible board and keep it there until the soldering is complete. This significantly improves the soldering yield. Additionally, it is recommended to have plated through holes (PTH) on the FPC’s gold fingers, which helps visually confirm the quality of the soldering and reduces the risk of solder overflow or short circuits. For mass production, manual soldering is strongly discouraged.

2. HotBar Soldering

HotBar soldering works on the principle of generating Joule heat by passing a pulse current through metals like molybdenum and titanium, which have high resistance. This heat warms the hot pressing head, which is then used to melt the solder paste printed on the PCB and connect it to the FPC, completing the soldering process. Therefore, HotBar soldering requires a HotBar machine and a carrier to fix the FPC to the PCB. As long as the FPC and PCB are designed correctly, mass production with a good yield is achievable.

3. Reflow Soldering

This method involves printing solder paste on the PCB, placing the FPC on it before reflow, and using a reflow carrier with a top cover and bottom seat to pass through the reflow oven. Magnetic clips are used to ensure the FPC stays in position and that the solder joints do not lift during the reflow process. However, this method is not suitable if components are placed beneath the FPC.

These are the three main methods for soldering FPC cables to PCBs. There are also two other methods—laser soldering and ACF (anisotropic conductive film)—but laser soldering equipment is not commonly used, and ACF has a significant drawback in that the adhesive can easily fail or peel off. Therefore, these methods are not covered in detail here.

If you're looking for a reliable and innovative flexible circuit board (FPC) manufacturer, Gekun is an excellent choice. With years of experience in the PCB industry, Gekun offers high-quality, precision-engineered flexible circuits that cater to a wide range of applications, from consumer electronics to industrial equipment. Gekun specializes in producing flexible PCBs with advanced features such as multi-layer designs, excellent durability, and high flexibility to meet the demands of modern technology.

Their commitment to quality is reflected in their cutting-edge manufacturing processes and rigorous quality control systems. Gekun also provides customization options, ensuring that your specific design requirements are met. Whether you need small batch production or large-scale manufacturing, Gekun’s solutions are tailored to help you achieve superior performance and reliability in your products.

Gekun web:https://gekunflex.com