Understanding Market Dynamics in the Aramid Fiber Market

The global aramid fiber market was valued at USD 4.09 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 8.1% from 2024 to 2030. This robust growth is primarily driven by increasing demand from various key industries, including oil & gas, healthcare, and manufacturing. The surge in demand for aramid fibers can largely be attributed to the rising stringency of government regulations concerning workplace safety. These regulations have prompted industries to adopt materials that provide enhanced protection and performance, which is expected to significantly fuel market growth throughout the forecast period.

Aramid fibers are known for their exceptional strength, heat resistance, and durability, making them highly suitable for applications in sectors where safety and high performance are essential. As safety regulations in industries such as oil & gas, manufacturing, and healthcare become more stringent, the demand for aramid fibers is anticipated to rise sharply. Aramid fibers are commonly used in protective clothing, safety equipment, and components that need to withstand high-stress conditions. This growing emphasis on safety and the increasing need for advanced materials is expected to drive the continued demand for aramid fibers in these sectors.

Gather more insights about the market drivers, restrains and growth of the Aramid Fiber Market

Product Insights

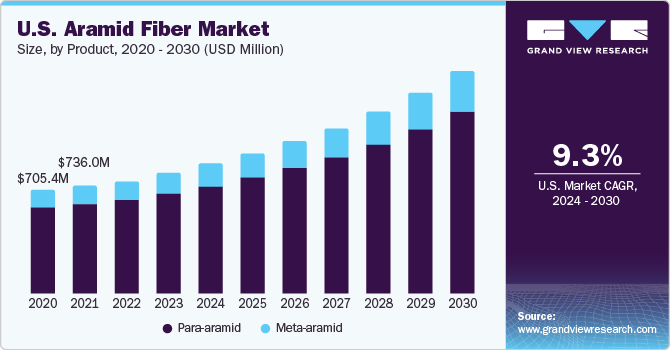

The aramid fiber market is dominated by two primary product segments: para-aramid and meta-aramid fibers. Among these, the para-aramid product segment held the largest share of the market in 2023, accounting for approximately 75.0% of total revenue. Para-aramid fibers are known for their superior strength-to-weight ratio, high tensile strength, and excellent modulus behavior. These fibers are particularly valued for their outstanding mechanical properties, which make them ideal for use in demanding applications where strength and durability are critical.

Para-aramid fibers exhibit several key properties that contribute to their high demand in various industries. These include low elongation to break, which provides added durability, and good chemical resistance, which makes them resistant to degradation in harsh environments. Additionally, para-aramids offer excellent heat and flame resistance, which makes them ideal for use in protective clothing, industrial applications, and military equipment. The ballistic properties of para-aramid fibers are another major advantage, as they are widely used in the production of body armor, ballistic vests, and other protective gear.

The high cut resistance and chemical resistance of para-aramid fibers also make them highly suitable for applications in the aerospace, security and protection, and frictional materials sectors. For example, para-aramid fibers are used extensively in the aerospace industry for manufacturing lightweight yet durable components such as ropes, cables, and insulation. In the defense and security sectors, they are used in the production of personal protective equipment, including helmets, vests, and gloves. These applications, along with growing demand from the automotive and manufacturing industries, are expected to continue driving the growth of the para-aramid fiber segment throughout the forecast period.

On the other hand, the meta-aramid product segment, although smaller in comparison to para-aramid, is also a significant contributor to the aramid fiber market. Meta-aramid fibers are produced using a wet spinning technology, which involves spinning the fiber in a chemical solution to form a semi-crystalline product. Meta-aramid fibers are known for their ability to withstand extreme tensile stress when exposed to high temperatures and flames, making them ideal for high-temperature applications.

In 2023, the meta-aramid fiber segment was valued at USD 1,023.0 million and is projected to experience considerable growth during the forecast period. Meta-aramid fibers are particularly well-suited for applications that require resistance to heat and flames, such as protective clothing for military personnel, auto racing suits, and firefighter uniforms. These fibers are also used extensively in electrical insulation, where their high-temperature resistance is crucial for maintaining the integrity and performance of electrical systems. The growing adoption of meta-aramid fibers in protective clothing and equipment, as well as in industries that require fire-resistant materials, is expected to fuel the segment's growth.

Order a free sample PDF of the Aramid Fiber Market Intelligence Study, published by Grand View Research.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology