A Comprehensive Guide to PC Hollow Sheets: Versatility and Applications

Understanding PC Hollow Sheets

PC hollow sheets, also known as polycarbonate hollow sheets, have emerged as a favored architectural and construction material due to their unique combination of properties. These sheets are lightweight yet incredibly strong, making them ideal for various applications. Polycarbonate, a type of thermoplastic, is characterized by excellent impact resistance, UV protection, and superior insulation properties. PC hollow sheets are manufactured with a hollow structure, which enhances their efficiency in thermal insulation while significantly reducing weight compared to solid polycarbonate sheets. As industries increasingly seek energy-efficient and durable materials, PC hollow sheets are becoming more than just a trend; they are a staple in modern construction.

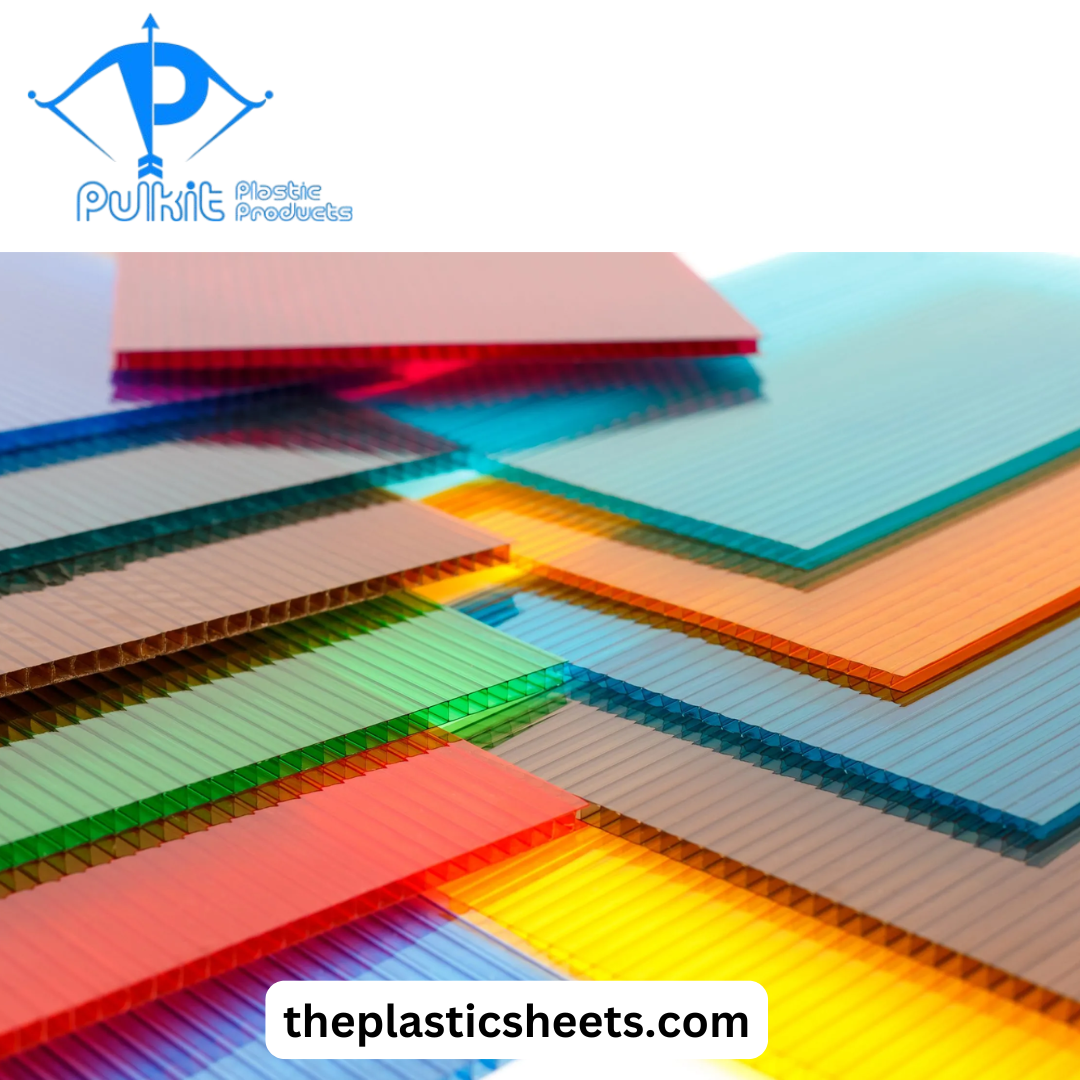

The Pulkit Plastic Products provides not only mechanical strength but also the capability to insulate against temperature fluctuations. This makes them particularly popular in environments where temperature control is crucial, such as greenhouses, skylights, and covered walkways. The sheets are often available in various colors and thicknesses, offering versatility and aesthetic choices for builders and architects alike. Whether for commercial, industrial, or residential purposes, the demand for PC hollow sheets continues to grow, driven by their functionality and adaptability.

Key Features of PC Hollow Sheets

One of the standout characteristics of PC hollow sheets is their exceptional durability. Resistant to both impact and weathering, they are suitable for various applications, ranging from roofing systems to curtain walls. Unlike traditional glass, which can shatter upon impact, polycarbonate sheets maintain structural integrity, making them a safer alternative in high-risk areas. Additionally, their lightweight nature allows for easier installation, reducing both labor costs and timeframes for construction projects.

Furthermore, these sheets often come with a UV protective coating that minimizes degradation from sunlight exposure, prolonging their lifespan significantly. This feature is particularly beneficial in outdoor setups, ensuring that the material does not yellow or lose transparency over time. Many manufacturers also provide warranties on their products, giving consumers peace of mind regarding the longevity and durability of their investment.

Another compelling feature of PC hollow sheets is their energy efficiency. The hollow design acts as an insulator, reducing heat transfer compared to solid sheets. This energy-saving quality can help lower heating and cooling costs in buildings, making them a favored choice in sustainable architecture. With increasing awareness of environmental issues, the demand for eco-friendly materials like PC hollow sheets continues to rise.

Applications of PC Hollow Sheets

The versatility of PC hollow sheets enables a wide range of applications across multiple industries. One of the most common uses for these sheets is in constructing greenhouses. The ability of Polycarbonate Sheet Near me to filter light while providing insulation creates an ideal environment for plants to thrive. Additionally, many gardeners and growers appreciate that these sheets are lightweight, making them easy to work with and install.

In the realm of construction and architecture, PC hollow sheets serve as an excellent solution for roofing and wall panels. They are often found in structures that prioritize natural lighting, such as atriums, skylights, and sunrooms. Their ability to diffuse light reduces glare while maximizing the amount of daylight entering the space, enhancing both aesthetic appeal and energy efficiency. Moreover, these sheets are also used in temporary structures, like event tents or fair booths, due to their ease of setup and dismantling.

PC hollow sheets are widely used in the signage industry. Their lightweight yet sturdy construction makes them ideal for various types of signage, from storefront displays to outdoor billboards. The sheets can be easily cut and shaped to meet custom requirements while providing excellent visibility and durability against the elements. With printing capabilities on many polycarbonate sheets, businesses can create vibrant and eye-catching signs that stand the test of time.

Factors Influencing Polycarbonate Sheet Price

When considering PC hollow sheets for a project, cost is a major factor for consumers. The polycarbonate sheet price can vary significantly based on several factors, including thickness, color, brand, and additional features such as UV resistance or insulation properties. Generally, thicker sheets provide better insulation and durability but come with a higher price tag. For builders and contractors, it is essential to balance budget constraints with quality and durability to ensure long-term satisfaction.

Additionally, sourcing and availability can also impact pricing. Consumers may find themselves asking, "Where can I find a polycarbonate sheet near me?" Local suppliers may sometimes charge higher prices due to shipping costs or limited stock. Conversely, purchasing directly from manufacturers or wholesalers can yield significant savings. Online platforms are also increasingly becoming a reliable option for sourcing these materials, allowing buyers to compare prices, features, and reviews easily.

Investors and project managers should also consider the long-term benefits of using PC hollow sheets, such as reduced energy costs and lower maintenance requirements. While the initial investment might be higher than traditional materials, the durability and energy efficiency of polycarbonate sheets often translate into savings over time, making them a smart choice for sustainable building design.

Environmental Impact and Sustainability

As the world increasingly shifts toward sustainability, the environmental impact of materials used in construction and manufacturing is under scrutiny. PC hollow sheets are recognized for their eco-friendliness due to their longevity and energy efficiency. When compared to glass or other conventional materials, the use of polycarbonate sheets can lead to lower greenhouse gas emissions during both production and use. Their lightweight nature also means lower energy consumption during transportation and installation.

Furthermore, many manufacturers are focused on producing recyclable polycarbonate products, helping to reduce landfill waste. As consumer awareness of environmental issues grows, builders and architects are actively seeking materials like PC hollow sheets that align with sustainable practices. By using these sheets, projects can effectively contribute to green building certification programs, such as LEED (Leadership in Energy and Environmental Design).

Beyond the production phase, the longevity of polycarbonate sheets also plays a crucial role in their environmental impact. Their resilience against weather conditions and UV radiation means fewer replacements are needed, leading to reduced resource consumption over time. Ultimately, investing in high-quality materials like PC hollow sheets supports sustainable development goals.

Installation and Maintenance of PC Hollow Sheets

Proper installation of PC hollow sheets is critical to maximizing their performance and longevity. While they can often be installed with minimal tools, it is essential to follow manufacturer guidelines to ensure proper sealing and alignment. Waterproofing seems to be a concern; hence the installation should include adequate spacing for thermal expansion and contraction, especially in regions with fluctuating temperatures. Additionally, utilizing the correct fasteners and support structures can enhance stability and prevent the sheets from warping over time.

Maintenance of PC hollow sheets is relatively straightforward, but some considerations should be noted to maintain their clarity and finish. Regular cleaning using mild soap and water, along with a soft cloth, can keep the sheets looking pristine. Avoid using harsh chemicals or abrasive materials, as these can scratch or damage the surface. For outdoor applications, occasional inspections of seals and support structures should be performed to ensure no issues arise.

The longevity of PC hollow sheets is one of their highlights, yet investing in proper installation and maintenance will further enhance their lifespan. With the right care, these sheets can provide a reliable and aesthetically pleasing solution for a multitude of projects.

Conclusion: The Value of PC Hollow Sheets

PC hollow sheets stand out as an exceptional building material in a world increasingly focused on sustainability and efficiency. Their unique balance of strength, durability, and insulating properties makes them highly versatile across various applications. From greenhouses and architectural features to advertising signage, they offer practical solutions in settings that require both function and aesthetics.

As the market for sustainable construction materials continues to grow, understanding the factors influencing purchasing decisions—such as Polycarbonate sheet price and availability—will empower consumers to make informed choices. By relying on locally sourced products and exploring online resources for competitive pricing, buyers can maximize the value of their investment.

Ultimately, PC hollow sheets represent a modern solution to age-old challenges in construction and design. By embracing this innovative material, we can contribute to a more sustainable future while also reaping the benefits of its impressive properties.

Frequently Asked Questions (FAQs)

1. What are the main advantages of using PC hollow sheets?

PC hollow sheets are lightweight, durable, impact-resistant, and offer excellent thermal insulation. They are also UV resistant, making them suitable for a variety of applications in construction and design.

2. How do I determine the best thickness for my polycarbonate sheet?

The ideal thickness depends on the application and environmental factors. Thicker sheets generally provide better insulation and durability, making them suitable for roofs and outdoor structures, while thinner sheets may suffice for signage and interior applications.

3. Can PC hollow sheets be cut and shaped easily?

Yes, PC hollow sheets can be cut and shaped using standard tools. However, it’s recommended to follow manufacturer guidelines for the best results, ensuring clean cuts and proper handling to avoid damage.

4. Are PC hollow sheets recyclable?

Yes, many polycarbonate sheets are recyclable. However, checking with local recycling facilities is essential to confirm specific acceptance policies and guidelines for recycling polycarbonate materials.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology