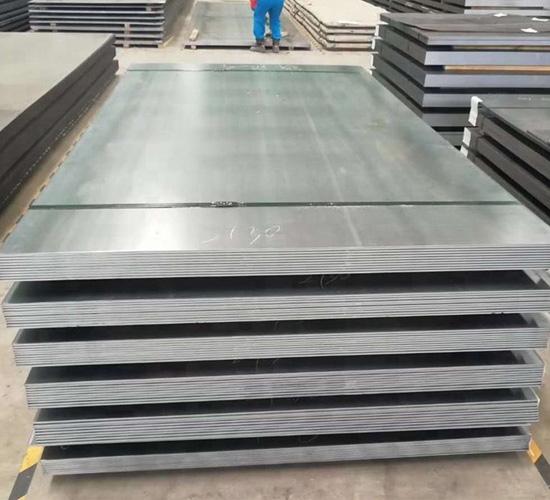

Mild steel sheets, also known as ms sheets, are one of the most versatile and widely used materials in various industries. Their low carbon content gives them the ideal balance between strength and flexibility, making them a cost-effective solution for numerous applications in sectors like construction, automotive, manufacturing, and more. These sheets are often chosen for their ease of fabrication, durability, and availability, making them an essential part of everyday operations across a wide array of industries.

In this article, we will explore the key characteristics of MS sheets, their common uses, the advantages they offer, and the factors influencing their market prices. By the end of this guide, you will have a clearer understanding of why MS sheets remain a staple material for manufacturers, contractors, and engineers alike.

Key Features and Benefits of MS Sheets

1. Strength and Durability

Despite being made from low-carbon steel, MS sheets are still remarkably strong and durable. They offer excellent tensile strength, which makes them suitable for applications requiring structural integrity. Whether used in the construction of buildings or for industrial machinery, MS sheets can withstand heavy loads and resist damage from stress, making them a reliable choice for long-lasting products.

2. Cost-Effective Solution

One of the major reasons for the popularity of MS sheets is their cost-effectiveness. Mild steel, being relatively inexpensive compared to other alloys like stainless steel, offers an affordable alternative for construction and manufacturing projects. For contractors, engineers, and manufacturers working on a budget, MS sheets provide an ideal balance of affordability and quality.

3. Ease of Fabrication and Customization

MS sheets are highly versatile and easy to work with. They can be cut, welded, and shaped into various forms depending on the specific requirements of a project. Whether you need large, flat panels or intricately shaped components, MS sheets can be customized to suit the task at hand.

4. Corrosion Resistance (To a Limited Extent)

While MS sheets are not as resistant to corrosion as stainless steel or other specialized alloys, they do offer some level of protection against the elements. Mild steel can be coated with materials like galvanization or paint to enhance its resistance to rust and corrosion, making MS sheets suitable for outdoor and industrial applications.

Common Applications of MS Sheets

1. Construction Industry

MS sheets are extensively used in the construction industry for a wide range of applications. From structural elements such as beams, columns, and frames to roofing sheets and wall panels, MS sheets are integral to building both residential and commercial properties. Their strength, malleability, and cost-effectiveness make them the ideal choice for large-scale construction projects.

2. Automotive Industry

In the automotive sector, MS sheets are used to manufacture vehicle body parts, including chassis, panels, and frames. The automotive industry relies on MS sheets for their ability to be easily shaped and welded into intricate forms while maintaining strength. As cars require both lightweight and durable components, MS sheets provide an excellent solution for vehicle manufacturing.

3. Fabrication and Manufacturing

MS sheets play a key role in the manufacturing and fabrication industries. They are used to create everything from machinery parts to storage tanks and heavy equipment. Their ability to be cut, drilled, and welded makes them perfect for the creation of custom machinery parts for factories and industrial operations.

4. Shipbuilding

The shipbuilding industry also relies heavily on MS sheets for constructing the hulls and other critical parts of ships and vessels. Their ability to withstand exposure to water, along with their flexibility and durability, makes MS sheets an essential material for maritime applications. Shipbuilders often coat MS sheets with corrosion-resistant materials to prevent rust, extending the lifespan of the vessels.

Factors Influencing MS Sheets Pricing

Several factors can impact the price of MS sheets. Understanding these factors can help buyers make informed decisions and budget accordingly for their projects.

1. Raw Material Prices

The price of MS sheets is directly affected by the cost of raw materials used in their production, such as iron ore, coal, and scrap steel. Any fluctuation in the price of these materials can lead to a rise or fall in the price of MS sheets. Global supply and demand for steel also play a role in determining the cost of these sheets.

2. Manufacturing Costs

The process of manufacturing MS sheets involves the use of energy, labor, and equipment, all of which contribute to the overall cost. The more energy-intensive or labor-intensive the production process, the higher the price of the sheets. Additionally, any improvements or changes in manufacturing techniques, such as automation or quality control measures, can influence the cost.

3. Market Demand

The demand for steel products, including MS sheets, is a key factor that drives prices. When demand is high due to construction booms, industrial projects, or seasonal requirements, the price of MS sheets may increase. Conversely, during periods of low demand, the price may stabilize or decrease.

How to Save on MS Sheets

To save on MS sheets, consider these strategies:

Bulk Purchases: Buying MS sheets in bulk often results in significant savings, as suppliers typically offer discounts for larger orders.

Shop Around: Prices can vary among different suppliers, so it’s important to compare quotes from multiple sources to ensure you are getting the best deal.

Negotiate: If you are purchasing a large quantity of MS sheets for a project, negotiating with suppliers can help you secure better pricing or additional discounts.

Monitor Market Trends: Keeping an eye on steel prices and market trends can help you time your purchase for when prices are lower.

Conclusion

MS sheets are an indispensable material used in various industries due to their strength, affordability, and versatility. From construction to automotive manufacturing, these sheets play a critical role in the production of a wide range of products and infrastructure. Understanding the benefits, applications, and pricing factors associated with MS sheets will help businesses and individuals make more informed decisions when it comes to purchasing and using these materials for their projects.

If you are looking for best quality tmt bars, please visit our website : www.steeloncall.com or you can contact us through our toll-free number: 18008332929