Sheet Metal Fabrication: Techniques, Applications, and Benefits

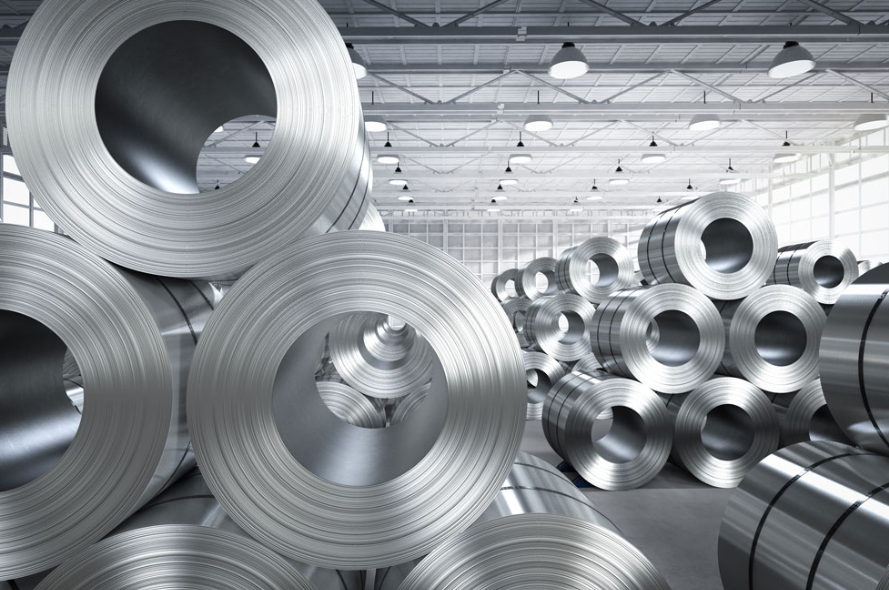

Sheet metal fabrication is a key process in manufacturing that involves shaping thin sheets of metal into various components and structures. From intricate car parts to simple brackets, sheet metal plays a significant role across industries. This guide covers the fundamentals of sheet metal fabrication, its processes, applications, and benefits.

What Is Sheet Metal Fabrication?

Sheet metal fabrication involves cutting, bending, forming, and assembling metal sheets to create functional components or products. Typically, the metal used ranges in thickness from 0.5 mm to 6 mm. Common metals include aluminum, stainless steel, brass, and copper, each offering different advantages depending on the application.

Fabrication transforms flat sheets into complex shapes and products using specialized tools, machinery, and skilled techniques.

Key Sheet Metal Fabrication Techniques

-

Cutting

The initial step involves cutting the metal sheet to the desired size. Popular methods include:- Laser Cutting: High precision, suitable for intricate designs.

- Water Jet Cutting: Uses high-pressure water; ideal for heat-sensitive materials.

- Plasma Cutting: Fast, cost-effective for thicker sheets.

- Shearing: Simple cutting with a machine blade, commonly used for straight cuts.

-

Bending

Metal sheets are bent to specific angles using:- Press Brakes: Most common tool for bending metal.

- Roll Bending: For creating cylindrical or conical shapes.

- Manual Bending: Useful for small-scale or custom jobs.

-

Punching

Punch presses create holes or shapes in the sheet metal. This is ideal for ventilation panels, brackets, or enclosures. -

Forming

Forming gives the sheet its final 3D shape. Methods like deep drawing (pulling the sheet into a mold) are used for items such as kitchen sinks or automotive panels. -

Welding

Multiple parts are joined together using welding techniques, such as MIG, TIG, or spot welding. -

Finishing

After fabrication, parts often need finishing processes like:- Powder Coating: Durable, protective finish.

- Anodizing: Used for aluminum to improve corrosion resistance.

- Polishing: Creates a shiny, reflective surface.

Applications of Sheet Metal Fabrication

-

Automotive Industry

Car bodies, chassis components, and exhaust systems rely heavily on sheet metal parts. -

Construction

Roofing, HVAC systems, and metal framing use fabricated sheet metal for durability and flexibility. -

Electronics

Enclosures, casings, and brackets for electronic devices are made using precise sheet metal fabrication. -

Aerospace

Aircraft bodies and internal components need lightweight, high-strength sheet metal materials. -

Medical Devices

Surgical instruments, medical enclosures, and equipment housing benefit from stainless steel and precision fabrication. -

Consumer Goods

Appliances, furniture, and decorative items are often made with sheet metal components.

Benefits of Sheet Metal Fabrication

- Durability: Fabricated metal parts are strong, resistant to wear, and can handle heavy loads.

- Customization: Flexible processes allow for highly customized components.

- Cost-Effective: Suitable for both small-batch and large-scale production.

- Precision: Modern technologies ensure tight tolerances and intricate designs.

- Sustainability: Metals like aluminum and steel are recyclable, reducing environmental impact.

Conclusion

Sheet metal fabrication remains a cornerstone of modern manufacturing, supporting industries ranging from aerospace to everyday consumer products. Advances in technology, such as CNC machining and laser cutting, continue to enhance precision and efficiency. With its versatility, durability, and wide range of applications, sheet metal fabrication is set to remain essential in the manufacturing landscape for years to come.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology