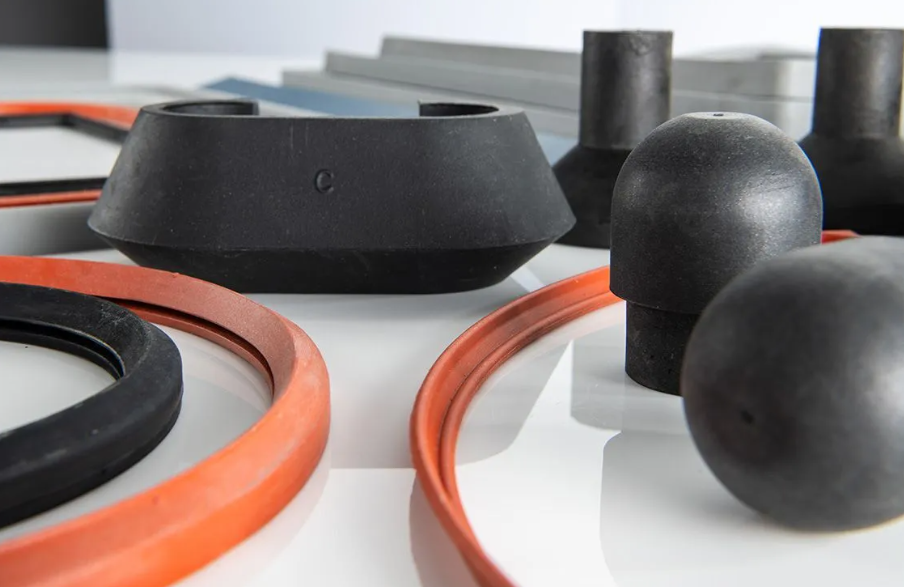

When it comes to industrial components, molded rubber products play a critical role in everything from automotive parts and construction materials to healthcare equipment and consumer goods. Choosing the right molded rubber manufacturer can significantly impact the quality, durability, and performance of your final product. But what exactly should you look for when selecting a manufacturer, and why is molded rubber manufacturing so essential?

What is Molded Rubber Manufacturing?

Molded rubber manufacturing is the process of creating custom or standardized rubber components by shaping raw rubber material into specific forms through molds. There are various techniques within molded rubber manufacturing, such as:

-

Compression Molding – Suitable for large or complex parts, this process involves placing pre-measured rubber into a heated mold and applying pressure until the rubber conforms to the shape.

-

Injection Molding – Ideal for high-volume production, rubber is injected into a closed mold under high pressure and heat.

-

Transfer Molding – A hybrid of compression and injection molding, this technique is used for intricate designs requiring precision.

Each method offers distinct advantages depending on the complexity, quantity, and specifications of the rubber component.

Applications of Molded Rubber Products

Molded rubber parts are used in a variety of industries. Common applications include:

-

Automotive – Seals, gaskets, hoses, and bushings that endure extreme temperatures and pressures.

-

Medical – Custom seals and tubing that meet strict safety and hygiene standards.

-

Aerospace – Vibration isolators and gaskets that require precise engineering.

-

Consumer Goods – Durable, flexible components in electronics, appliances, and sporting equipment.

Key Qualities of a Reliable Molded Rubber Manufacturer

Selecting the right manufacturer involves more than just cost-efficiency. Here are critical factors to consider:

1. Material Expertise

A reputable manufacturer should offer expertise in a variety of rubber compounds, such as:

-

EPDM (Ethylene Propylene Diene Monomer) – Excellent for outdoor applications due to its resistance to weather and UV exposure.

-

Nitrile (NBR) – Ideal for oil and fuel resistance.

-

Silicone – Perfect for medical and food-grade applications due to its heat resistance and flexibility.

-

Neoprene – Versatile and durable, suitable for industrial gaskets and hoses.

2. Custom Capabilities

Not all projects are the same. A good manufacturer should be able to create custom molds and designs to meet unique specifications. Look for companies that provide design assistance, prototyping, and rapid tooling.

3. Quality Control

Consistency is key in rubber manufacturing. Ensure that the manufacturer follows rigorous quality standards like ISO 9001 certification. Processes such as thorough material testing, dimensional inspections, and final product evaluations are essential for maintaining quality.

4. Experience and Industry Knowledge

Longevity in the industry often correlates with expertise. Manufacturers with years of experience are more likely to understand the nuances of different applications and materials.

5. Production Capacity

Whether you need small batches or large-scale production, the manufacturer should have the capacity to meet your deadlines without compromising quality.

The Importance of Sustainability in Molded Rubber Manufacturing

As industries become more eco-conscious, sustainability is increasingly crucial in rubber manufacturing. Reputable manufacturers now adopt practices like:

-

Using recycled rubber or sustainable raw materials.

-

Implementing waste reduction strategies.

-

Ensuring environmentally friendly production processes.

Choosing a manufacturer committed to sustainability can help reduce your company’s environmental footprint.

Leading Molded Rubber Manufacturers in the Market

Several companies stand out in the molded rubber industry due to their quality, innovation, and customer service. Some notable manufacturers include:

-

Minnesota Rubber and Plastics – Known for their technical expertise and high-performance solutions.

-

Rubber Industries, Inc. – Offers fast turnaround times and a wide range of molding capabilities.

-

Timco Rubber – Provides customized rubber solutions with a focus on customer collaboration.

Conclusion

Selecting the right molded rubber manufacturer is critical for ensuring the quality and reliability of your products. By evaluating their material knowledge, production capabilities, quality control processes, and commitment to sustainability, you can partner with a manufacturer that aligns with your specific needs. Investing time in finding the right manufacturing partner ultimately leads to better performance, lower costs, and greater customer satisfaction.