Understanding IML Die Cutting Machines and Their Essential Components for Efficient Label Production

In the modern world of packaging, labels are more than just decorative elements. They serve critical purposes, from conveying important product information to establishing a brand's identity. To achieve high-quality labels efficiently, manufacturers rely on advanced machinery, such as IML (In-Mold Label) Die Cutting Machines, label die cutting machines, UV curing systems, label slitting machines, and hot foil stamping machines. Each of these machines plays a pivotal role in creating labels that meet the demands of the market.

This blog will take you through the ins and outs of these machines and explore how they work together to streamline the label production process.

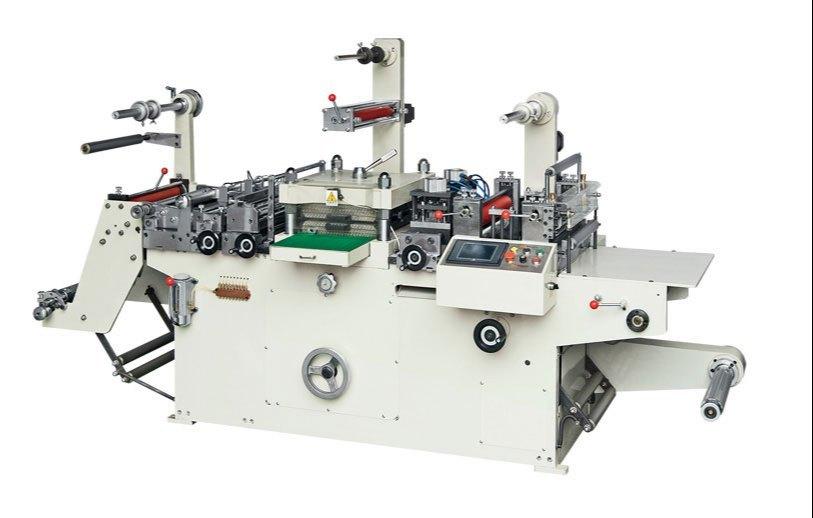

IML Die Cutting Machine: Revolutionizing Label Production

An IML Die Cutting Machine is an advanced piece of equipment designed for cutting In-Mold Labels. These labels are applied to products during the molding process, ensuring that they are permanently fused to the surface. Unlike traditional labeling techniques, which require adhesives, IML labels are integrated directly into the product’s design, offering a more durable and aesthetically pleasing result.

The IML Die Cutting Machine uses high-precision cutting methods to create these labels from various materials, including paper, plastic, and foil. It ensures consistent cuts with minimal waste, improving the overall efficiency of the production process. This machine’s ability to handle high volumes while maintaining precision makes it an essential tool for manufacturers in the packaging and labeling industries.

The benefits of using an IML Die Cutting Machine include:

- Enhanced Durability: IML labels are more durable because they are molded into the product, offering better resistance to wear and tear compared to traditional adhesive labels.

- Aesthetic Appeal: The integration of labels during molding allows for seamless, high-quality designs that are visually appealing.

- Cost Efficiency: With minimal material waste and a streamlined production process, manufacturers can save on costs while producing high-quality labels.

Label Die Cutting Machines: Precision and Flexibility

A label die cutting machine is another key player in the world of label production. These machines are designed to cut labels into various shapes and sizes with high precision. Typically used in the packaging industry, they are essential for creating custom labels that fit a wide range of products.

The label die cutting machine can cut through different materials, including paper, vinyl, and synthetic films. The machine works by using a die—a sharp, precisely crafted tool that cuts through the material in the desired shape. The cutting process is highly customizable, allowing manufacturers to create unique label designs that suit their specific needs.

The advantages of label die cutting machines include:

- Customization: Manufacturers can create labels of various shapes, sizes, and designs to match their branding and product packaging needs.

- Speed and Efficiency: The machines operate at high speeds, ensuring that large quantities of labels are produced in a short amount of time without compromising on quality.

- Versatility: These machines can handle different types of materials, making them suitable for a wide range of applications.

UV Curing Systems: Enhancing Print Quality

UV curing systems are integral to modern label printing processes, particularly when it comes to printing labels with vibrant colors and intricate designs. UV curing involves the use of ultraviolet light to dry and cure ink instantly as it is printed onto the label material. This technology helps to produce high-quality, durable prints that are resistant to fading, smudging, and scratching.

In a typical label production process, UV curing systems work alongside printing machines to ensure that the ink dries quickly and adheres properly to the label material. The use of UV light allows manufacturers to achieve vibrant, crisp prints with faster turnaround times.

The benefits of UV curing systems include:

- Quick Drying Time: UV curing eliminates the need for drying time, which speeds up the production process.

- Durability: UV-cured prints are more resistant to wear, making them ideal for labels that will be exposed to harsh conditions.

- Eco-Friendly: UV curing produces fewer volatile organic compounds (VOCs) than traditional drying methods, making it a more environmentally friendly option.

Label Slitting Machines: Ensuring Clean Cuts and Efficient Label Separation

A label slitting machine is essential for cutting large rolls of printed labels into smaller, individual labels. Once the labels have been printed, they often come in large rolls that need to be cut into smaller sections to be used on products. A label slitting machine performs this task with precision, ensuring that the labels are evenly cut and ready for application.

These machines work by using rotating blades to slice through the printed material, cutting it into the desired widths. Label slitting machines can be highly customized to handle various label sizes and materials, making them a versatile solution for manufacturers.

The advantages of label slitting machines include:

- High Precision: The machines ensure that labels are cut evenly and accurately, preventing wastage.

- Increased Productivity: Label slitting machines can operate at high speeds, allowing manufacturers to process large quantities of labels in a short amount of time.

- Flexibility: These machines can accommodate different label sizes, shapes, and materials, making them suitable for a wide range of label production needs.

Hot Foil Stamping Machines: Adding a Touch of Luxury to Labels

Hot foil stamping machines are used to apply metallic or holographic foil designs onto labels, giving them a premium and sophisticated appearance. This process involves applying heat and pressure to transfer the foil onto the label material, creating eye-catching effects that can enhance the product’s appeal.

Hot foil stamping is commonly used in high-end packaging, where brands want their products to stand out on the shelves. The process allows for the creation of intricate designs, including logos, brand names, and decorative elements that catch the consumer’s eye.

The benefits of hot foil stamping machines include:

- Premium Aesthetic: The metallic or holographic finishes created by hot foil stamping add a high-end touch to the product, making it more attractive to consumers.

- Customizability: Manufacturers can create unique and intricate designs using foil stamping, enhancing the label's overall design.

- Durability: Foil stamping provides a durable finish that is resistant to fading and scratching.

Conclusion: The Synergy of Die Cutting Machines and Label Production Equipment

The world of label production is complex, involving numerous machines that each serve a specific purpose. The IML Die Cutting Machine, label die cutting machines, UV curing systems, label slitting machines, and hot foil stamping machines work together to produce labels that are not only visually appealing but also durable and functional.

Manufacturers that invest in these advanced machines can expect to see improvements in efficiency, precision, and the quality of their labels. By understanding how these machines complement each other, businesses can streamline their production processes and deliver high-quality products to the market faster and more cost-effectively.

For businesses looking to enhance their label production capabilities, it's essential to partner with a trusted manufacturer of these advanced machines. Companies like GTI (https://www.gtigti.com) provide innovative solutions that ensure your production line stays ahead of the competition, helping you deliver exceptional labels that leave a lasting impression on consumers.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology