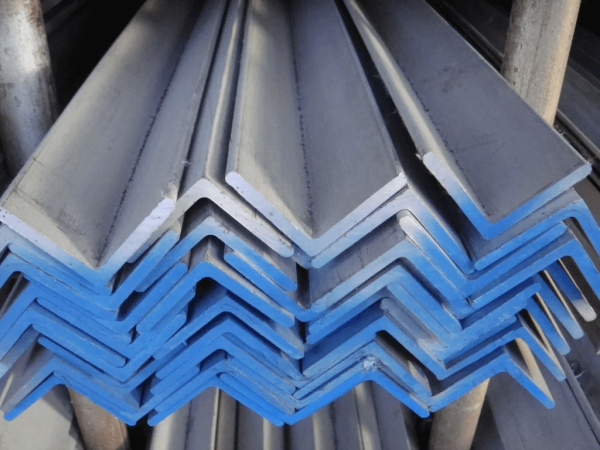

Angle Bar – The Essential Structural Component for Strength & Stability

Why Angle Bar is a Must-Have for Construction and Fabrication

An Angle Bar is a fundamental component in construction, engineering, and manufacturing. Known for its L-shaped design, it provides excellent support and reinforcement in various applications. Whether used in structural frameworks, furniture making, or heavy-duty projects, an Angle Bar ensures durability and stability.

Key Benefits of Using Angle Bar

-

Versatile Applications: Angle bars are widely used in construction, metal fabrication, and reinforcement work.

-

Strength & Durability: Designed to handle heavy loads, they provide structural support in buildings and machinery.

-

Corrosion Resistance: Depending on the material, these bars offer long-lasting performance in different environments.

-

Easy to Work With: Whether for welding, drilling, or bolting, they can be easily modified to fit project requirements.

-

Cost-Effective: Angle bars offer a budget-friendly solution for strong and stable structural support.

The Role of Mild Steel in Angle Bar Manufacturing

One of the most common materials for angle bars is Mild Steel, known for its strength and affordability. Mild Steel angle bars are widely used in various industries due to their excellent mechanical properties. Here’s why Mild Steel is a preferred choice:

-

High Strength & Toughness: Mild Steel provides a strong foundation for construction projects.

-

Easy to Weld & Shape: Mild Steel angle bars can be customized to fit specific design needs.

-

Durable & Long-Lasting: Despite its affordability, Mild Steel offers remarkable longevity.

-

Resistant to Wear & Tear: Perfect for heavy-duty applications, Mild Steel maintains its integrity over time.

-

Ideal for Industrial & Residential Use: From bridges to furniture, Mild Steel angle bars are used in multiple sectors.

Choosing the Right Angle Bar for Your Project

When selecting an Angle Bar, consider factors like:

-

Material Type: Mild steel, stainless steel, or galvanized options based on project needs.

-

Size & Thickness: Ensure proper dimensions for load-bearing requirements.

-

Coating & Finish: Additional coatings provide corrosion resistance in harsh environments.

-

Project Specifications: Match the angle bar with intended use, whether for construction, machinery, or decorative purposes.

Steel Beam vs. Angle Bar – Understanding the Difference

While an Angle Bar is ideal for structural reinforcement, a Steel Beam plays a different role in construction. A Steel Beam provides vertical and horizontal support in large-scale projects like bridges and buildings. Here’s why a Steel Beam is often paired with an Angle Bar:

-

Enhanced Load Distribution: A Steel Beam works alongside an angle bar for improved weight distribution.

-

Structural Integrity: Using both ensures better stability in high-rise buildings.

-

Heavy-Duty Performance: A Steel Beam offers additional support in load-bearing applications.

-

Greater Flexibility in Design: Combining an Angle Bar with a Steel Beam allows for complex structural designs.

Conclusion

An Angle Bar is an essential component in various industries, offering strength, versatility, and durability. Whether made from Mild Steel or combined with a Steel Beam, it provides crucial support in construction and engineering projects. Choosing the right angle bar ensures stability and long-lasting performance in any application.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology