How does light remove rust without physically touching the metal

The process you're describing is laser cleaning metal, a fascinating application of light and material science. It's a method that leverages the unique properties of lasers to remove contaminants, like rust, paint, or other coatings, from metal surfaces without the need for abrasive blasting, chemical solvents, or other traditional cleaning methods. The key lies in understanding how light interacts with different materials at a microscopic level.

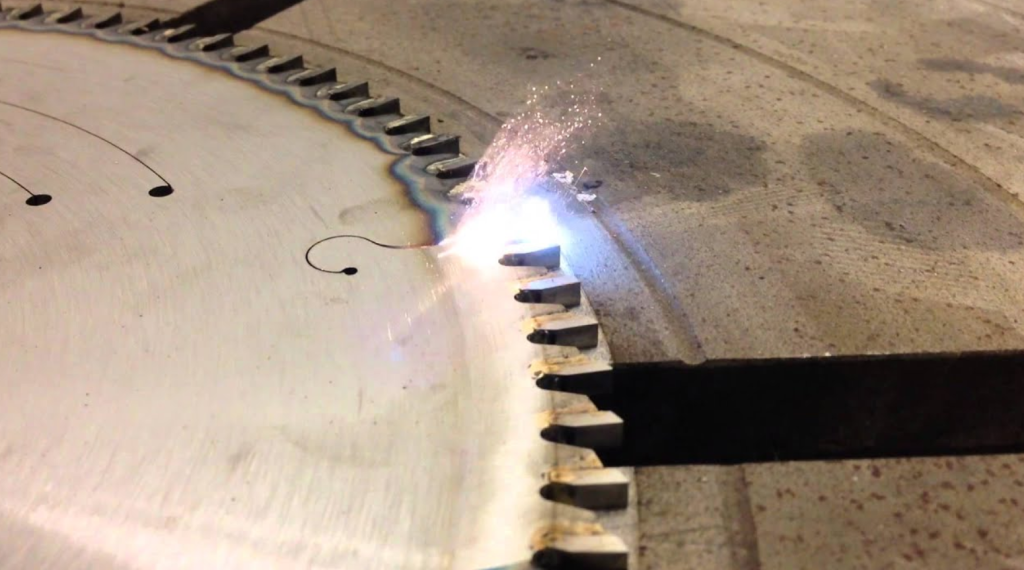

Laser cleaning metal isn't about simply blasting away the rust with brute force. Instead, it's a precisely controlled process that relies on the principle of selective absorption.

Different materials absorb light at different wavelengths and with varying degrees of efficiency. Rust, for example, absorbs laser light of a specific wavelength much more readily than the underlying metal. This difference in absorption is crucial to the entire process.

When a laser is used for laser cleaning metal, it emits pulses of light at a carefully chosen wavelength. This wavelength is selected specifically because it is highly absorbed by the contaminant (like rust) but poorly absorbed by the base metal. Think of it like tuning a radio to a specific frequency. The rust is "tuned in" to the laser's frequency, while the metal is not.

When the laser pulse strikes the rust, the rust absorbs the energy from the light. This absorbed energy causes the rust to rapidly heat up. This rapid heating leads to several possible effects, depending on the intensity and duration of the laser pulse.

One primary effect is that the rust can vaporize or sublimate. Vaporization is the process of a solid turning directly into a gas, while sublimation is similar but involves a phase change from solid to gas without going through a liquid phase. The intense energy of the laser pulse causes the rust to make this transition, effectively removing it from the metal surface.

Another effect that can occur is that the rust can be broken down into tiny particles. These particles can then be ejected from the surface due to the rapid expansion of the vaporized material or the force of the laser pulse itself. This process is sometimes referred to as ablation.

It's important to understand that the laser cleaning metal process is highly controlled. The power of the laser, the duration of the pulses, and the wavelength of the light are all carefully chosen to ensure that the rust is removed effectively without damaging the underlying metal. Because the metal reflects much of the laser energy and doesn't absorb it readily, it doesn't experience the same rapid heating as the rust. This selectivity is what allows laser cleaning to be so precise.

The process is often described as "non-contact" cleaning because the laser beam itself never physically touches the metal surface. The cleaning happens due to the interaction of the light with the rust. This non-contact nature is one of the significant aspects of laser cleaning metal, as it avoids the wear and tear associated with traditional cleaning methods.

The physics behind laser cleaning metal involves complex interactions between light and matter. The process isn't simply about heating the rust. It involves phenomena like photoablation, where the material is removed due to the breaking of chemical bonds by the laser light, and photothermal effects, where the material is removed due to the rapid heating and vaporization.

The specific mechanisms involved in laser cleaning metal can vary depending on the type of laser used, the wavelength of the light, the properties of the rust, and the type of metal being cleaned. Different lasers emit light at different wavelengths, and these wavelengths interact differently with various materials. For example, some lasers might be better suited for removing certain types of rust, while others might be more effective for removing paint or other coatings.

Furthermore, the condition of the metal surface itself can influence the laser cleaning metal process. If the metal is highly reflective, it will reflect more of the laser light, making it more difficult to remove the rust. Conversely, if the metal surface is rough or porous, it might trap some of the vaporized or ablated material, making it necessary to use a more powerful laser or multiple passes to achieve complete cleaning.

The precision of laser cleaning metal is a key factor in its increasing popularity. It allows for the removal of contaminants from very small or intricate areas without affecting the surrounding material. This makes it particularly useful in applications where precision is critical, such as the restoration of historical artifacts or the cleaning of delicate electronic components.

In summary, laser cleaning metal leverages the principle of selective absorption to remove contaminants from metal surfaces. By carefully choosing the wavelength and power of the laser, it's possible to vaporize or ablate the rust without damaging the underlying metal. This non-contact and precise cleaning method is revolutionizing various industries, offering a more efficient and environmentally friendly alternative to traditional cleaning techniques. The process is a testament to the power of light and its ability to interact with matter in highly specific and controlled ways.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology