The Impact of 5G Connectivity on Sensor Fusion Market Technology in Industrial IoT: Enhancing Real-Time Data Processing, Smarter Automation, and Operational Efficiency Across Key Sectors

The rapid growth of the Internet of Things (IoT) has revolutionized industries, and with the emergence of 5G technology, its influence is only increasing. One of the key technologies driving innovation in industrial applications is sensor fusion. The combination of sensor data from various sources into a cohesive, actionable format is essential for enhanced decision-making and smarter automation. 5G connectivity plays a pivotal role in enabling the next level of sensor fusion in Industrial IoT (IIoT), empowering real-time analytics, faster data processing, and more intelligent operations. This article explores how 5G is enhancing Sensor Fusion Market in the Industrial IoT landscape.

What is Sensor Fusion?

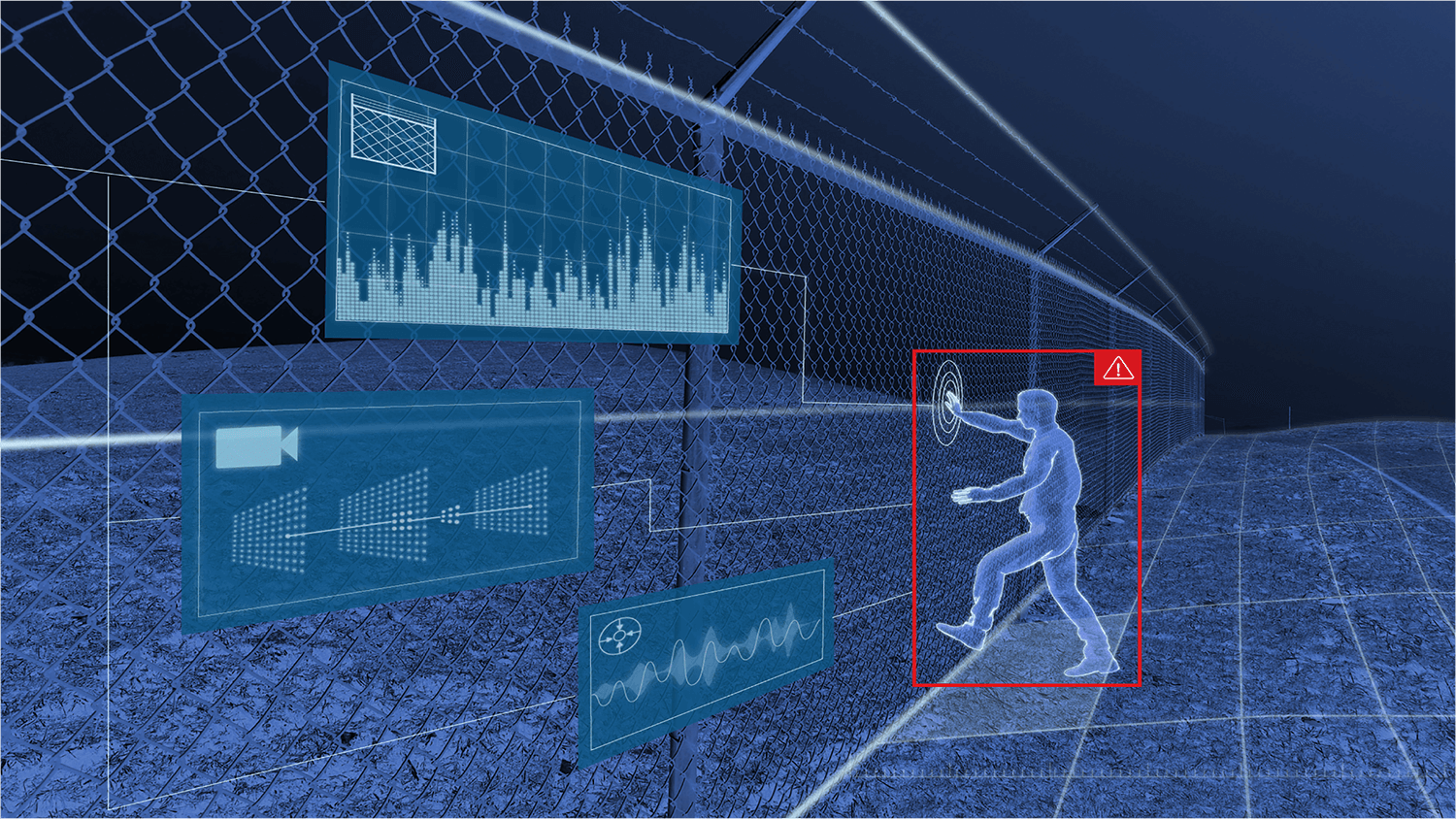

Sensor fusion refers to the integration of data from multiple sensors to provide more accurate and comprehensive information than any single sensor could provide on its own. This technology combines data from different sensor types (e.g., temperature, humidity, pressure, motion, proximity) to create a unified view of a system or environment. In industrial settings, sensor fusion enables organizations to monitor conditions in real time, detect anomalies, optimize processes, and improve efficiency.

The Role of 5G in Sensor Fusion

5G technology, with its high-speed connectivity, low latency, and large bandwidth capabilities, is transforming the way data is transmitted and processed in IIoT applications. Sensor fusion, which typically involves large amounts of data, can benefit significantly from 5G's ability to handle real-time communications and rapid data transfers. The main ways 5G impacts sensor fusion in IIoT are:

- Faster Data Transfer and Processing: 5G offers download speeds that are 10 to 100 times faster than 4G, making it possible to transfer large amounts of sensor data almost instantaneously. In industrial environments, where hundreds or even thousands of sensors may be deployed across various machines or devices, the ability to quickly aggregate and transmit data allows for more accurate and timely decision-making. With 5G, the latency between data collection and processing is dramatically reduced, enabling real-time sensor fusion in environments such as factories, energy grids, and supply chains.

- Real-Time Analytics and Decision Making: Sensor fusion is highly dependent on the ability to process data in real time. 5G’s ultra-low latency enables real-time analytics by allowing data to be processed almost as soon as it is captured. In manufacturing, for example, machine data can be analyzed in real-time to predict potential failures, optimize production schedules, and automate processes. This rapid feedback loop results in more agile operations, reduced downtime, and the ability to react quickly to changing conditions in industrial settings.

- Smarter Automation and Control: With 5G, industrial systems can integrate various sensor data sources seamlessly, enabling smarter automation. For example, in an industrial IoT environment, machines equipped with multiple sensors can exchange real-time data with each other and central processing systems. 5G connectivity supports the creation of intelligent control systems that can adjust settings dynamically based on the data received, leading to more efficient operations. In energy grids, for example, 5G-connected sensors can optimize energy distribution based on real-time usage data, minimizing waste and ensuring grid stability.

- Support for Edge and Cloud Computing: The combination of edge computing and cloud computing, made possible by 5G, is crucial for efficient sensor fusion. Edge computing processes data locally at the sensor level, reducing the need for data transmission to central servers and minimizing latency. This is particularly important in applications like autonomous vehicles, where real-time decisions are critical. In contrast, cloud computing handles larger datasets and provides advanced analytics tools. With 5G, data from sensors can be sent to both edge devices for immediate processing and to the cloud for deeper analysis and long-term storage, offering a balanced approach to sensor fusion in IIoT.

Applications of Sensor Fusion Enhanced by 5G in Industrial IoT

The potential of 5G-powered sensor fusion in industrial applications is vast. Here are some key sectors where this technology is having a significant impact:

- Manufacturing: In smart factories, sensor fusion technology is used to monitor machines, equipment, and the overall production line. With 5G, data from sensors across the plant floor can be instantly processed to detect potential equipment failures, prevent downtime, and automate production processes. Predictive maintenance is one of the most notable applications, where sensor fusion helps detect signs of wear or malfunction in machines before they fail, leading to increased operational efficiency.

- Energy Grids: 5G is playing a pivotal role in optimizing energy distribution and consumption. Sensors installed in power plants, transformers, and power lines collect vast amounts of data related to voltage, current, temperature, and pressure. By utilizing sensor fusion in real time, energy providers can respond quickly to faults, optimize grid management, and improve energy efficiency. Additionally, with 5G’s support for edge computing, sensor data can be processed closer to the source, reducing latency and enabling faster decision-making during peak demand or faults.

- Logistics and Supply Chain Management: The logistics sector benefits significantly from sensor fusion enabled by 5G connectivity. Sensors in vehicles, warehouses, and shipping containers can monitor temperature, humidity, location, and motion, providing valuable data for inventory management and supply chain optimization. With the power of 5G, logistics companies can track shipments in real time, predict delays, and ensure goods are transported under optimal conditions. This leads to improved customer service, reduced costs, and greater efficiency across the supply chain.

- Autonomous Vehicles: Sensor fusion plays a crucial role in enabling autonomous vehicles to navigate their environments safely. Vehicles rely on multiple sensors (LiDAR, radar, cameras, GPS) to perceive their surroundings. 5G’s low latency and high bandwidth allow for the fast transmission of sensor data to support real-time decision-making in autonomous driving systems. By enabling vehicles to communicate with each other and infrastructure (V2X), 5G enhances sensor fusion and improves safety, navigation, and route optimization.

- Smart Agriculture: Agriculture is another industry benefitting from 5G-enabled sensor fusion. Sensors embedded in soil, weather stations, irrigation systems, and drones gather data that can be fused to monitor crop health, optimize water usage, and detect environmental changes. With 5G, farmers can receive real-time updates, improve resource management, and enhance crop yields by making data-driven decisions faster.

Challenges in Integrating 5G with Sensor Fusion

While 5G offers tremendous potential, its integration with sensor fusion in industrial IoT applications is not without challenges:

- Infrastructure Costs: Deploying 5G networks requires significant investment in infrastructure, including base stations, antennas, and compatible devices. Small and medium-sized enterprises may find these costs prohibitive, limiting the accessibility of 5G for sensor fusion applications.

- Security Concerns: With the increased interconnectivity that 5G enables, security becomes a critical concern. Industrial IoT systems often control critical infrastructure, and any breach could have disastrous consequences. Ensuring robust cybersecurity measures to protect the data and networks involved in sensor fusion is essential for successful adoption.

- Interoperability: The variety of sensors and devices used in IIoT applications may not always be compatible with 5G networks. Ensuring interoperability between different types of sensors, networks, and systems is necessary for achieving the full potential of sensor fusion.

Conclusion

5G technology is driving the evolution of sensor fusion in Industrial IoT, enabling faster data processing, real-time analytics, and smarter automation. The ability of 5G to support high-speed, low-latency communication empowers industries to make data-driven decisions quickly and effectively. From manufacturing and energy grids to logistics and autonomous vehicles, 5G-enhanced sensor fusion is optimizing processes, reducing costs, and improving operational efficiency. While there are challenges to overcome, the integration of 5G with sensor fusion holds enormous potential for transforming industrial sectors and propelling them into a new era of automation and connectivity.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology