The Role of Eccentric Arc Sintered NdFeB Magnets in Electric Motors

In the evolving world of electric motors, the need for high performance and energy-efficient solutions is driving innovation in magnetic materials. Among these advances, eccentric arc sintered neodymium iron boron (NdFeB) magnets have become a key component in optimizing motor performance. These high-strength, precisely shaped magnets offer significant advantages in terms of increased efficiency, torque density, and overall operational reliability. This article explores the importance of https://www.abm-magnetics.com/Eccentric-Arc-Sintered-Neodymium-Iron-Boron-Magnet.html in electric motors, detailing their unique properties, benefits, and performance.

Understanding NdFeB Magnets and Their Role in Electric Motors

NdFeB magnets are the strongest commercially available permanent magnets today, known for their exceptional magnetic properties, including high remanence, coercivity, and energy product. Their widespread adoption in electric motors stems from their ability to generate strong magnetic fields within compact spaces, enabling more efficient motor designs.

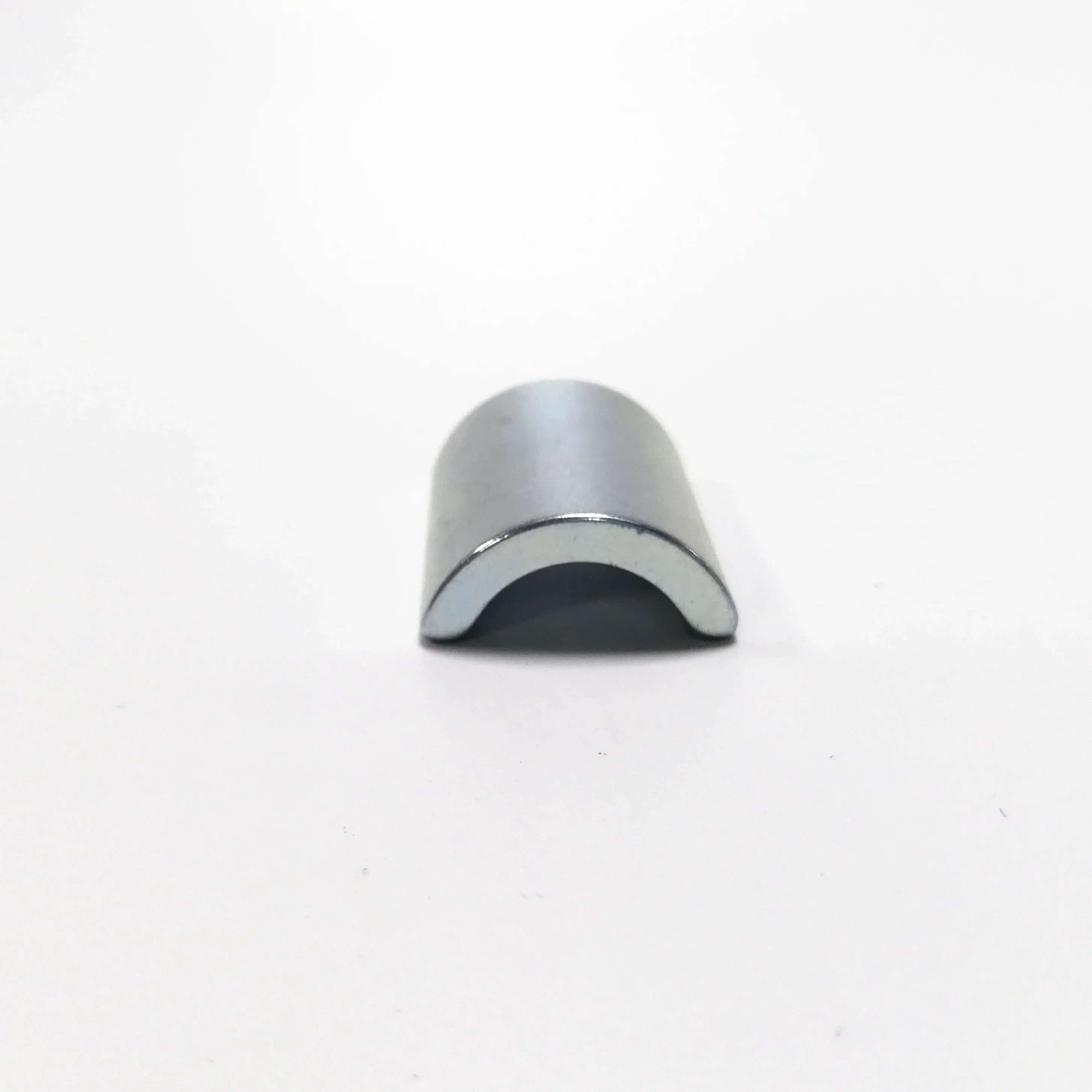

Eccentric arc sintered NdFeB magnets are specifically engineered to fit the unique geometries required in electric motor applications. Unlike traditional straight or standard arc magnets, eccentric arc magnets are designed with an off-center curvature that enhances flux distribution and minimizes losses in motor operations.

Key Properties of Eccentric Arc Sintered NdFeB Magnets

Eccentric arc sintered NdFeB magnets possess several properties that make them highly suitable for electric motor applications:

High Magnetic Strength: They offer superior remanence and coercivity, resulting in strong and stable magnetic fields.

Precise Geometry: The eccentric arc design allows for an optimized fit within rotor and stator assemblies, improving flux concentration.

Temperature Resistance: Advanced sintering techniques enhance their thermal stability, making them suitable for high-temperature motor operations.

Durability: The sintered structure improves mechanical robustness, reducing the likelihood of chipping or demagnetization.

Advantages of Using Eccentric Arc Sintered NdFeB Magnets in Electric Motors

1. Enhanced Magnetic Efficiency

Eccentric arc sintered NdFeB magnets improve magnetic circuit design by concentrating the flux in desired regions, reducing unwanted leakage and optimizing torque output. This ensures that electric motors achieve higher efficiency levels while consuming less energy.

2. Reduced Cogging Torque

Cogging torque, caused by the interaction between the rotor magnets and stator slots, leads to unwanted pulsations in motor operation. The eccentric arc geometry mitigates these effects by distributing the magnetic field more evenly, resulting in smoother motor performance and reduced vibrations.

3. Higher Torque Density and Power Output

By refining the shape of the magnet to align better with the motor’s magnetic field, eccentric arc NdFeB magnets contribute to higher torque density. This enables electric motors to generate greater power output without increasing size, making them ideal for space-constrained applications such as electric vehicles (EVs) and industrial automation.

4. Improved Thermal Stability and Reliability

Electric motors often operate under high temperatures, which can affect magnet performance. The sintering process used in these magnets enhances their resistance to demagnetization at elevated temperatures, ensuring reliable operation in demanding environments.

5. Compact and Lightweight Design

Due to their strong magnetic properties, NdFeB magnets allow for the design of smaller, lighter motors without compromising power. This is particularly beneficial in industries where weight reduction is a priority, such as aerospace and consumer electronics.

Conclusion

Eccentric arc sintered NdFeB magnets play a crucial role in advancing electric motor technology by offering enhanced efficiency, reduced cogging torque, and superior power density. Their application across various industries, from electric vehicles to renewable energy, underscores their significance in modern engineering. As technological advancements continue, these magnets will remain a cornerstone in the quest for more efficient and powerful electric motors, driving the future of sustainable and high-performance electromechanical systems.

Eccentric Arc Sintered NdFeB Magnets: A Precision Solution from ABM Magnetics

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology