Real-Time Viscosity Monitoring in Lube Oil Blending: New Sensor Technologies

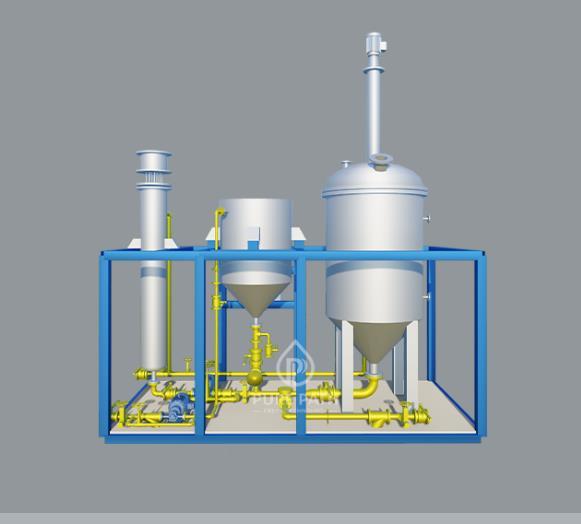

The lubricant industry is constantly evolving, with a growing emphasis on precision, efficiency, and quality control. One critical parameter in lube oil blending is viscosity—the measure of a fluid’s resistance to flow. Maintaining optimal viscosity ensures that the final product meets performance specifications for engines, industrial machinery, and other applications.

Traditionally, viscosity measurement in lube oil blending has relied on offline laboratory testing, which can be time-consuming and may lead to delays in process adjustments. However, advancements in sensor technology now enable real-time viscosity monitoring, revolutionizing the blending process.

The Need for Real-Time Viscosity Monitoring

Viscosity is a key quality indicator for lubricants, affecting film strength, wear protection, and energy efficiency. Inconsistent viscosity can lead to:

Poor lubrication performance

Increased engine wear

Higher energy consumption

Product rejections and compliance issues

By integrating real-time viscosity sensors, manufacturers can:

✔ Reduce blending time by eliminating lab-testing delays

✔ Improve batch consistency with instant feedback

✔ Minimize waste by detecting deviations early

✔ Enhance automation for smarter process control

Emerging Sensor Technologies for Viscosity Monitoring

Several advanced sensor technologies are now being deployed in lube oil blending plants:

1. Vibrational Viscometers

These sensors measure viscosity by analyzing the damping effect of the fluid on an oscillating probe. They provide continuous, in-line readings without requiring sample extraction.

2. Microfluidic Sensors

Using microchannels and pressure drop measurements, these compact sensors offer high-precision viscosity data, even for low-viscosity oils.

3. Ultrasonic Viscosity Sensors

By sending ultrasonic waves through the fluid, these sensors detect changes in viscosity based on wave attenuation and speed. They are ideal for harsh industrial environments.

4. Optical Viscometers

These sensors use light scattering or refraction techniques to determine viscosity, offering non-invasive monitoring suitable for clean blending systems.

Benefits of Real-Time Viscosity Control

Faster adjustments: Immediate feedback allows operators to tweak blend ratios instantly.

Cost savings: Reduces off-spec batches and rework.

Data integration: Compatible with Industry 4.0 and IoT platforms for predictive maintenance.

The Future of Smart Blending

As sensor technology continues to advance, real-time viscosity monitoring will become a standard in lube oil production. Combined with AI-driven analytics, these systems will enable fully automated, self-optimizing blending processes—ensuring higher efficiency and superior product quality.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology