Global Surgical Sutures Market Forecast to 2035

The new report titled ‘Global Surgical Sutures Market,’ published by Roots Analysis, is a vivid presentation of the global Surgical Sutures market, with utmost focus on the forecast market size, share, value, and volume over the projected timeline. The report throws light on the current economic landscape of this business vertical and evaluates the top market trends. It has been compiled through significant primary research, including surveys, interviews, and expert analysts’ observations. It features insightful qualitative and quantitative assessments of the Surgical Sutures industry, gathering industry-verified data from the value chain analysis. The report, additionally, examines the prevailing trends in the market, along with the macro- and micro-economic indicators. The report delivers a deep understanding of the key aspects of the Surgical Sutures market, for instance, import and export dynamics, production and consumption rates, and consumer bases across the major market regions. Thus, the report concludes with the essential market statistics presented in a tabular format to help readers get a clear idea of the global market dynamics.

This report comprehensively analyzes the impact of the pandemic on the Surgical Sutures market and its major segments. Additionally, the report also includes an analysis of the current and future impact of the pandemic on market growth.

Research Report on the Surgical Sutures Market Addresses the Following Key Questions:

• Who are the dominant players of the Surgical Sutures market?

• Which regional market is anticipated to have a high growth rate over the projected period?

• What consumer trends and demands are expected to influence the operations of the market players in the Surgical Sutures market?

• What are the key growth drivers and restraining factors of the Surgical Sutures market?

• What are the expansion plans and strategic investment plans undertaken by the players to gain a robust footing in the market?

• What is the overall impact of the COVID-19 pandemic on the Surgical Sutures market and its key segments?

Surgical Sutures Market Segmenation:

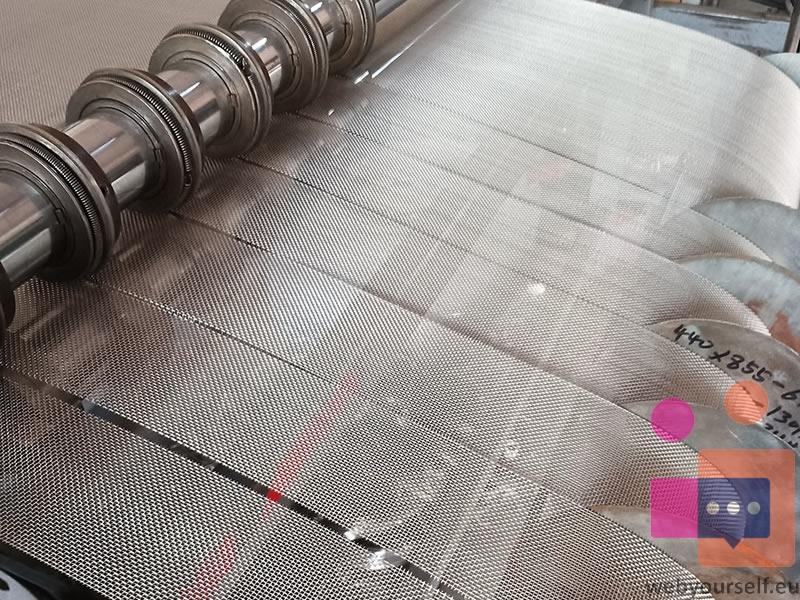

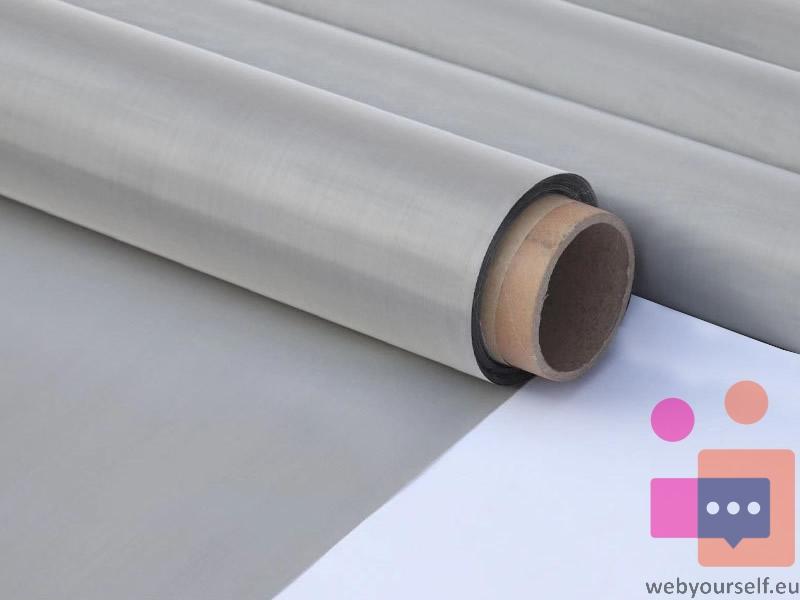

Surgical Sutures Market: Industry Trends and Global Forecasts to 2035 - Distribution by Product Type (Absorbable and Non-Absorbable), by Material (Natural, Polypropylene, Stainless Steel, Others), by Coating (Non-Coated, Antimicrobial and Others), by Filament Type (Monofilament and Multifilament), by Applications (Ophthalmic Surgery, Cardiovascular Surgery, Orthopedic Surgery, Neurological Surgery and Other Applications), End Users (Hospitals, Surgical Centers, and Clinics / Physician Offices), Others

The report bifurcates the Surgical Sutures market on the basis of different product types, applications, end-user industries, and key regions of the world where the market has already established its presence. The report accurately offers insights into the supply-demand ratio and production and consumption volume of each segment.

Key Companies Profiled in the Report:

• Apollo Endosurgery

• Boston Scientific Corporation

• DemeTECH

• Ethicon

• Internacional Farmacéutica

• Medtronic

• Mellon Medical

• Peters Surgical

• Smith & Nephew

• Sutures India

Regional Landscape section of the Surgical Sutures report offers deeper insights into the regulatory framework, current and emerging market trends, production and consumption patterns, supply and demand dynamics, import/export, and presence of major players in each region.

The various regions analyzed in the report include:

• North America (U.S., Canada)

• Europe (U.K., Italy, Germany, France, Rest of EU)

• Asia Pacific (India, Japan, China, South Korea, Australia, Rest of APAC)

• Latin America (Chile, Brazil, Argentina, Rest of Latin America)

• Middle East & Africa (Saudi Arabia, U.A.E., South Africa, Rest of MEA)

To know more about the report, visit @

https://www.rootsanalysis.com/reports/surgical-sutures-market.html

The section on the competitive landscape offers valuable and actionable insights related to the business sphere of the Surgical Sutures market, covering extensive profiling of the key market players. The report offers information about market share, product portfolio, pricing analysis, and strategic alliances such as mergers and acquisitions, joint ventures, collaborations, partnerships, product launches and brand promotions, among others. The report also discusses the initiatives taken by the key companies to combat the impact of the COVID-19 pandemic.

Thank you for reading our report. To know more about the customization feature, please get in touch with us, and our team will ensure the report is customized to meet your requirements.

About Roots Analysis

Roots Analysis is a global leader in the pharma / biotech market research. Having worked with over 750 clients worldwide, including Fortune 500 companies, start-ups, academia, venture catalysts, and strategic investors for more than a decade, we offer a highly analytical / data-driven perspective to a network of over 450,000 senior industry stakeholders looking for credible market insights. All reports provided by us are structured in a way that enables the reader to develop a thorough perspective on the given subject. Apart from writing reports on identified areas, we provide bespoke research / consulting services dedicated to serving our clients in the best possible way.

The research efforts are driven by a global team. The leadership team brings a wealth of experience within the sector. Their collective experience in pharmaceutical / affiliated domains allows us to tackle various areas of research in a structured way. We also regularly leverage our global network of experts who hold senior leadership positions in reputed firms and organizations worldwide.

All our analysts are trained to produce high-quality research work. They are continuously mentored by senior experts to present an original, unbiased and informed perspective on pressing issues in the industry. On any particular subject, we bring together the best available resources to ensure highest quality in all our reports.

Contact Details

Roots Analysis

Gaurav Chaudhary

+1 (415) 800 3415

+44 (122) 391 1091

Gaurav.chaudhary@rootsanalysis.com

Website:

https://www.rootsanalysis.com/ Global Surgical Sutures Market Forecast to 2035

The new report titled ‘Global Surgical Sutures Market,’ published by Roots Analysis, is a vivid presentation of the global Surgical Sutures market, with utmost focus on the forecast market size, share, value, and volume over the projected timeline. The report throws light on the current economic landscape of this business vertical and evaluates the top market trends. It has been compiled through significant primary research, including surveys, interviews, and expert analysts’ observations. It features insightful qualitative and quantitative assessments of the Surgical Sutures industry, gathering industry-verified data from the value chain analysis. The report, additionally, examines the prevailing trends in the market, along with the macro- and micro-economic indicators. The report delivers a deep understanding of the key aspects of the Surgical Sutures market, for instance, import and export dynamics, production and consumption rates, and consumer bases across the major market regions. Thus, the report concludes with the essential market statistics presented in a tabular format to help readers get a clear idea of the global market dynamics.

This report comprehensively analyzes the impact of the pandemic on the Surgical Sutures market and its major segments. Additionally, the report also includes an analysis of the current and future impact of the pandemic on market growth.

Research Report on the Surgical Sutures Market Addresses the Following Key Questions:

• Who are the dominant players of the Surgical Sutures market?

• Which regional market is anticipated to have a high growth rate over the projected period?

• What consumer trends and demands are expected to influence the operations of the market players in the Surgical Sutures market?

• What are the key growth drivers and restraining factors of the Surgical Sutures market?

• What are the expansion plans and strategic investment plans undertaken by the players to gain a robust footing in the market?

• What is the overall impact of the COVID-19 pandemic on the Surgical Sutures market and its key segments?

Surgical Sutures Market Segmenation:

Surgical Sutures Market: Industry Trends and Global Forecasts to 2035 - Distribution by Product Type (Absorbable and Non-Absorbable), by Material (Natural, Polypropylene, Stainless Steel, Others), by Coating (Non-Coated, Antimicrobial and Others), by Filament Type (Monofilament and Multifilament), by Applications (Ophthalmic Surgery, Cardiovascular Surgery, Orthopedic Surgery, Neurological Surgery and Other Applications), End Users (Hospitals, Surgical Centers, and Clinics / Physician Offices), Others

The report bifurcates the Surgical Sutures market on the basis of different product types, applications, end-user industries, and key regions of the world where the market has already established its presence. The report accurately offers insights into the supply-demand ratio and production and consumption volume of each segment.

Key Companies Profiled in the Report:

• Apollo Endosurgery

• Boston Scientific Corporation

• DemeTECH

• Ethicon

• Internacional Farmacéutica

• Medtronic

• Mellon Medical

• Peters Surgical

• Smith & Nephew

• Sutures India

Regional Landscape section of the Surgical Sutures report offers deeper insights into the regulatory framework, current and emerging market trends, production and consumption patterns, supply and demand dynamics, import/export, and presence of major players in each region.

The various regions analyzed in the report include:

• North America (U.S., Canada)

• Europe (U.K., Italy, Germany, France, Rest of EU)

• Asia Pacific (India, Japan, China, South Korea, Australia, Rest of APAC)

• Latin America (Chile, Brazil, Argentina, Rest of Latin America)

• Middle East & Africa (Saudi Arabia, U.A.E., South Africa, Rest of MEA)

To know more about the report, visit @ https://www.rootsanalysis.com/reports/surgical-sutures-market.html

The section on the competitive landscape offers valuable and actionable insights related to the business sphere of the Surgical Sutures market, covering extensive profiling of the key market players. The report offers information about market share, product portfolio, pricing analysis, and strategic alliances such as mergers and acquisitions, joint ventures, collaborations, partnerships, product launches and brand promotions, among others. The report also discusses the initiatives taken by the key companies to combat the impact of the COVID-19 pandemic.

Thank you for reading our report. To know more about the customization feature, please get in touch with us, and our team will ensure the report is customized to meet your requirements.

About Roots Analysis

Roots Analysis is a global leader in the pharma / biotech market research. Having worked with over 750 clients worldwide, including Fortune 500 companies, start-ups, academia, venture catalysts, and strategic investors for more than a decade, we offer a highly analytical / data-driven perspective to a network of over 450,000 senior industry stakeholders looking for credible market insights. All reports provided by us are structured in a way that enables the reader to develop a thorough perspective on the given subject. Apart from writing reports on identified areas, we provide bespoke research / consulting services dedicated to serving our clients in the best possible way.

The research efforts are driven by a global team. The leadership team brings a wealth of experience within the sector. Their collective experience in pharmaceutical / affiliated domains allows us to tackle various areas of research in a structured way. We also regularly leverage our global network of experts who hold senior leadership positions in reputed firms and organizations worldwide.

All our analysts are trained to produce high-quality research work. They are continuously mentored by senior experts to present an original, unbiased and informed perspective on pressing issues in the industry. On any particular subject, we bring together the best available resources to ensure highest quality in all our reports.

Contact Details

Roots Analysis

Gaurav Chaudhary

+1 (415) 800 3415

+44 (122) 391 1091

Gaurav.chaudhary@rootsanalysis.com

Website: https://www.rootsanalysis.com/