Advanced Automation in Lube Oil Blending Plants – Enhancing Precision and Efficiency

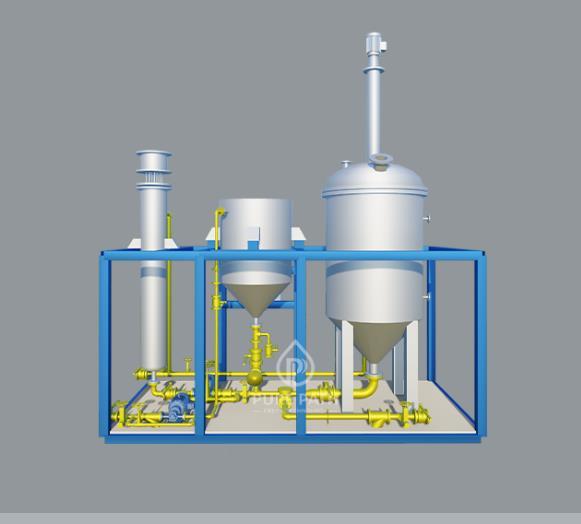

Lube oil blending is a complex process that requires precise control over base oils and additives to meet stringent quality standards. Traditional manual blending methods are prone to inconsistencies, leading to product variability and increased waste. To overcome these challenges, modern lube oil blending plants are adopting advanced automation technologies, ensuring higher accuracy, efficiency, and cost savings.

Key Automation Technologies in Lube Oil Blending

1. Automated Batch Blending Systems

Automated batch blending uses PLC (Programmable Logic Controller) and DCS (Distributed Control System) to precisely control ingredient dosing, mixing time, and temperature. These systems eliminate human error, ensuring each batch meets exact viscosity, additive concentration, and performance specifications.

2. In-Line Quality Monitoring with NIR Spectroscopy

Near-infrared (NIR) spectroscopy is increasingly used for real-time quality control. Sensors analyze the chemical composition of blended oil as it flows through pipelines, instantly detecting deviations from target specifications. If inconsistencies are found, the system automatically adjusts the blend ratio, reducing off-spec production.

3. AI-Driven Predictive Blending Optimization

Artificial intelligence (AI) algorithms analyze historical blending data, raw material variability, and equipment performance to optimize formulations. AI can predict the best blending sequences, minimizing additive waste and energy consumption while maintaining product consistency.

4. Robotics for Additive Handling

Many additives are hazardous or require precise handling. Robotic dispensers ensure accurate dosing while reducing worker exposure to chemicals. Automated guided vehicles (AGVs) further streamline material transport within the plant.

Benefits of Automation in Lube Oil Blending

Higher Product Consistency – Reduced batch-to-batch variations.

Lower Operational Costs – Minimized additive waste and energy use.

Faster Production Cycles – Automated systems blend oils faster than manual methods.

Improved Safety – Reduced human intervention in hazardous processes.

Conclusion

Automation is revolutionizing lube oil blending by enhancing precision, efficiency, and safety. As plants adopt AI, robotics, and real-time analytics, they gain a competitive edge in producing high-quality lubricants with minimal waste. The future of blending lies in smart, data-driven operations—are you ready to embrace it?

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology