High-Power Rectifiers Market Strengths: Powering the Future of Industrial Electronics

The High-Power Rectifiers Market strengths lie in their indispensable role in converting alternating current (AC) into direct current (DC), a process critical to the functioning of numerous industrial, commercial, and consumer electronic applications. These devices are designed to handle large electrical loads and maintain high efficiency, reliability, and durability in challenging environments. As industries continue to modernize and embrace electrification, the demand for high-power rectifiers is experiencing robust growth, driven by advancements in technology and expanding applications.

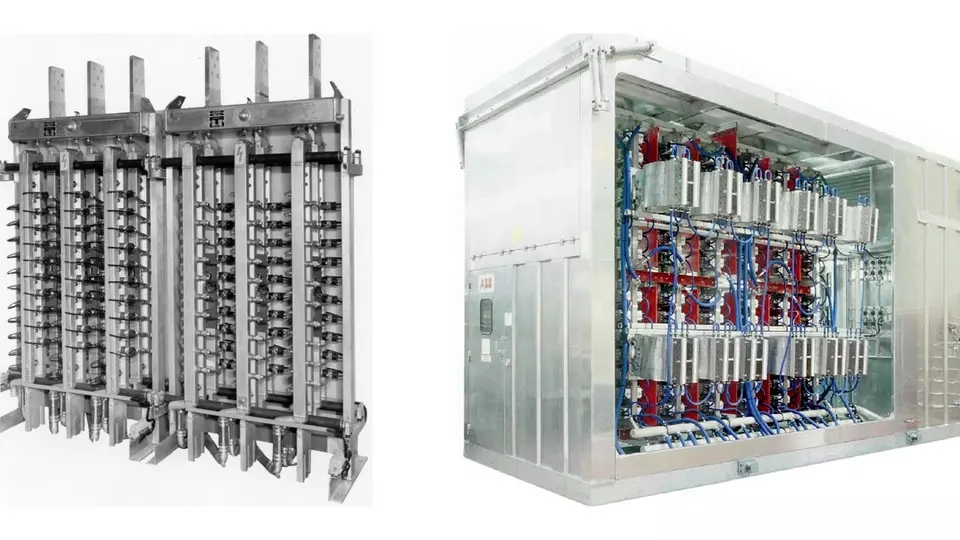

Robust Performance in Demanding Applications

One of the core strengths of high-power rectifiers is their ability to perform efficiently under extreme conditions. Unlike standard rectifiers, which are typically used for lower power applications, high-power rectifiers are engineered to handle significant voltages and currents without degradation. This capability makes them essential in sectors like power generation, electric vehicles (EVs), renewable energy systems, and industrial automation.

For example, in power plants and substations, high-power rectifiers ensure smooth and stable DC power output, which is vital for consistent energy supply. Their rugged design helps them withstand high temperatures, voltage spikes, and mechanical stress, thereby enhancing system reliability and reducing maintenance costs.

Enabling Renewable Energy Integration

The growing shift towards renewable energy sources such as solar and wind power is a major growth driver for the high-power rectifiers market. Renewable energy systems typically generate variable AC power, which must be converted to DC for storage or grid integration. High-power rectifiers facilitate this critical conversion efficiently, helping to maximize energy capture and minimize losses.

Moreover, with the increasing deployment of large-scale solar farms and wind turbines, the need for robust rectification solutions capable of managing high power outputs has intensified. Rectifiers also play a key role in battery storage systems, which store DC power before it is converted back to AC for consumer use, ensuring the stability and reliability of renewable energy grids.

Advancements in Semiconductor Technology

Technological innovations in semiconductor materials have significantly enhanced the capabilities of high-power rectifiers. Traditionally made from silicon, rectifiers are increasingly being manufactured using wide bandgap materials such as silicon carbide (SiC) and gallium nitride (GaN). These materials offer superior electrical properties, including higher breakdown voltages, faster switching speeds, and better thermal conductivity.

Such advancements enable rectifiers to operate at higher efficiencies and temperatures, reduce energy losses, and allow for more compact designs. The integration of these materials in rectifiers supports the development of next-generation industrial equipment that is more energy-efficient and environmentally friendly.

Versatility Across Industrial Sectors

High-power rectifiers find applications across a broad spectrum of industries, underscoring their market strength through versatility. In the automotive sector, they are integral to electric vehicle charging stations and onboard power electronics, helping facilitate faster and more efficient charging processes.

In heavy industries such as mining, metal processing, and manufacturing, high-power rectifiers control electric furnaces, electroplating systems, and DC motor drives. Their ability to deliver consistent DC power helps improve process precision and productivity while minimizing downtime.

Additionally, the telecommunications industry relies on rectifiers to provide uninterruptible power supplies (UPS) that safeguard critical communication infrastructure against power disruptions.

Growing Demand from Electric Vehicle Market

The rapid rise of electric vehicles worldwide is fueling demand for high-power rectifiers. As EV manufacturers push for higher battery capacities and faster charging solutions, rectifiers capable of managing high currents and voltages are crucial. They are a key component in charging stations and power converters within the vehicles themselves.

High-power rectifiers enable fast DC charging by efficiently converting AC from the grid to DC suitable for battery storage, reducing charging time significantly. The expansion of EV infrastructure globally will continue to boost the high-power rectifiers market, with innovations focusing on miniaturization and improved thermal management to support the stringent requirements of automotive applications.

Impact of Industrial Automation and Smart Grids

The rise of Industry 4.0 and smart grid technologies has intensified the need for reliable power conversion components. High-power rectifiers contribute to the efficient operation of automated manufacturing lines by powering DC motors, robotics, and control systems with precise and stable current supply.

Smart grids, which integrate distributed energy resources and enable real-time monitoring of power flows, rely heavily on advanced rectification technologies. Rectifiers help in bidirectional power conversion, energy storage management, and voltage regulation, supporting the grid’s flexibility and resilience.

Challenges and Market Opportunities

While the high-power rectifiers market boasts numerous strengths, it also faces challenges such as the need for continuous innovation to improve efficiency and reduce thermal losses. The harsh operating environments in certain industries demand constant improvements in device robustness and lifespan.

However, these challenges present opportunities for manufacturers to develop novel cooling techniques, smart monitoring systems, and compact form factors. The increasing focus on sustainability and energy efficiency encourages the adoption of cutting-edge rectifier technologies that minimize environmental impact.

Regional Market Insights

Asia-Pacific leads the high-power rectifiers market due to rapid industrialization, expanding renewable energy projects, and the growing electric vehicle market. China, Japan, and South Korea are key contributors, with strong investments in infrastructure and manufacturing.

North America and Europe follow closely, driven by the demand for automation, renewable energy integration, and the electric vehicle boom. Government incentives supporting clean energy and electric mobility further accelerate market growth in these regions.

Future Outlook

The future of the high-power rectifiers market is bright, powered by technological advancements and the growing global emphasis on energy-efficient solutions. As industries continue to digitalize and electrify, the demand for reliable and high-performance rectifiers will rise.

Emerging trends such as the adoption of wide bandgap semiconductors, integration with smart power electronics, and the expansion of EV infrastructure are expected to shape the market landscape. Manufacturers focusing on innovation, sustainability, and customized solutions will be best positioned to capitalize on the evolving needs of industrial and commercial sectors.

Conclusion

The High-Power Rectifiers Market strengths are evident in its critical role across diverse applications requiring reliable DC power conversion at high voltages and currents. With robust performance, versatility, and continuous technological innovation, high-power rectifiers are set to be a foundational component in the ongoing global shift towards electrification and sustainable energy solutions.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness

- IT, Cloud, Software and Technology