How to Wire a Solar Panel to an LED Light

Are you looking to save energy and reduce your electricity bill? Installing solar panels and using the generated power to light up your garden or driveway is a smart long-term decision. Not only will it save you money, but it's also environmentally friendly. In this guide, we will show you step-by-step how to wire a solar panel to an LED light, allowing you to set up your very own solar panel system without the need for an electrician.

>>> See More LED strip is getting dim over time at

https://gettr.com/post/p2q2cwi2912

The Things You Will Need

To wire a solar panel to an LED light, you will need the following items:

A solar panel

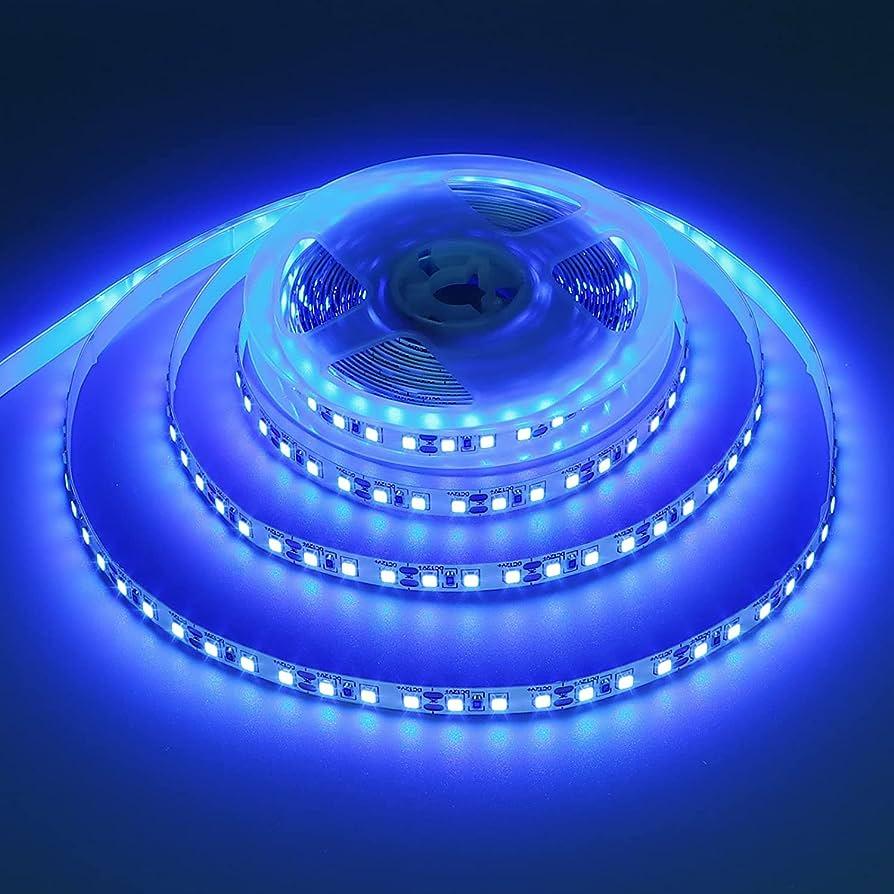

LED light

LED controller

Wires

Connectors

Wire Stripper

Crimping tool

Screwdriver

Soldering iron

Don't worry about needing a large or powerful solar panel. Since an LED light requires only a small amount of power, a modest panel will suffice. If you have a wiring diagram that comes with the solar panel, great! If not, don't worry. The process is simple and we will guide you.

Wiring a Solar Panel to an LED Light

A Simple Method

If you want to get the job done quickly and without **** effort, this simple method is perfect for you. All you need are the solar panel, LED light, LED controller (optional), two wires, and a resistor.

Let's start by inspecting the **** of the solar panel. You will find two terminals with polarities marked on them. One will be marked positive (+) and the other negative (-). Connect the like polarities using wires and insert a resistor in the positive wire. Here's a wiring diagram to help you visualize the process:

To wire the solar panel to the LED light using this simple method, follow these steps:

Strip the wire ends (about half an inch).

Connect the wires using a crimping tool.

Attach each wire to the corresponding connector as indicated in the wiring diagram.

Connect the solar panel to the LED controller using these connectors.

Secure the connections with a screwdriver.

Connect the LED controller to the LED light.

Congratulations! You can now power the LED light using your solar panel.

You can also wire a separate LED light in the circuit as an indicator to visually indicate whether the solar panel is on or off.

>>> See More A Radiant Review of Tatazone 2000K Yellow COB LED Strip Lights with RF Remote at

https://bestledlightstripsblls.blogspot.com/2023/08/a-radiant-review-of-tatazone-2000k.html

Other Components You Can Include

If you want more control over your LED light's operation, you can add additional components to the solar panel-LED circuit. Here are some options:

Switch: Add a switch to control the circuit, enabling you to turn it on or off.

Rechargeable Battery: Include a rechargeable battery if you want to use the LED light at times when there is no sunlight.

Charge Controller: Prevent the batteries from overcharging by adding a charge controller (recommended if you have more than 5 watts of solar power for each 100 AH of battery capacity).

Capacitor: Smooth out interruptions caused by obstacles blocking the light source by adding a capacitor.

PNP Transistor: Use a transistor to detect darkness levels.

Diode: Ensure the current flows in one direction, from the solar panel to the LED lamp and batteries.

If you add rechargeable batteries, make sure to include a diode in the circuit to allow current to flow only in one direction, from the solar panel to the battery.

Testing the Current

Sometimes, you may need to test the current for brightness or other power issues with the LED light. Here's a simple method using a low-powered LED in electronic circuits:

Step 1: Prepare the Multimeter

Set the multimeter to measure DC in the range of 200 mA.

Step 2: Connect the Test Lead

Connect the solar panel's red wire to the long LED lead using an alligator clip test lead. Then, connect the multimeter's red probe to the LED's short lead and its black probe to the solar panel's black wire. This will form a series circuit.

Step 3: Test an LED

Position the LED about one foot above the panel and turn it on. The LED should light up. If it doesn't, double-check the wiring and multimeter settings.

Step 4: Check the Current

Read the current on the multimeter to see exactly how **** current is passing through the LED. Compare this reading to the LED's specifications to ensure it meets the required current.

>>> See More How does remote control functionality work with yellow LED strip lights at

https://www.flickr.com/photos/bestledlightstripsblls/53152738681How to Wire a Solar Panel to an LED Light

Are you looking to save energy and reduce your electricity bill? Installing solar panels and using the generated power to light up your garden or driveway is a smart long-term decision. Not only will it save you money, but it's also environmentally friendly. In this guide, we will show you step-by-step how to wire a solar panel to an LED light, allowing you to set up your very own solar panel system without the need for an electrician.

>>> See More LED strip is getting dim over time at https://gettr.com/post/p2q2cwi2912

The Things You Will Need

To wire a solar panel to an LED light, you will need the following items:

A solar panel

LED light

LED controller

Wires

Connectors

Wire Stripper

Crimping tool

Screwdriver

Soldering iron

Don't worry about needing a large or powerful solar panel. Since an LED light requires only a small amount of power, a modest panel will suffice. If you have a wiring diagram that comes with the solar panel, great! If not, don't worry. The process is simple and we will guide you.

Wiring a Solar Panel to an LED Light

A Simple Method

If you want to get the job done quickly and without much effort, this simple method is perfect for you. All you need are the solar panel, LED light, LED controller (optional), two wires, and a resistor.

Let's start by inspecting the back of the solar panel. You will find two terminals with polarities marked on them. One will be marked positive (+) and the other negative (-). Connect the like polarities using wires and insert a resistor in the positive wire. Here's a wiring diagram to help you visualize the process:

To wire the solar panel to the LED light using this simple method, follow these steps:

Strip the wire ends (about half an inch).

Connect the wires using a crimping tool.

Attach each wire to the corresponding connector as indicated in the wiring diagram.

Connect the solar panel to the LED controller using these connectors.

Secure the connections with a screwdriver.

Connect the LED controller to the LED light.

Congratulations! You can now power the LED light using your solar panel.

You can also wire a separate LED light in the circuit as an indicator to visually indicate whether the solar panel is on or off.

>>> See More A Radiant Review of Tatazone 2000K Yellow COB LED Strip Lights with RF Remote at https://bestledlightstripsblls.blogspot.com/2023/08/a-radiant-review-of-tatazone-2000k.html

Other Components You Can Include

If you want more control over your LED light's operation, you can add additional components to the solar panel-LED circuit. Here are some options:

Switch: Add a switch to control the circuit, enabling you to turn it on or off.

Rechargeable Battery: Include a rechargeable battery if you want to use the LED light at times when there is no sunlight.

Charge Controller: Prevent the batteries from overcharging by adding a charge controller (recommended if you have more than 5 watts of solar power for each 100 AH of battery capacity).

Capacitor: Smooth out interruptions caused by obstacles blocking the light source by adding a capacitor.

PNP Transistor: Use a transistor to detect darkness levels.

Diode: Ensure the current flows in one direction, from the solar panel to the LED lamp and batteries.

If you add rechargeable batteries, make sure to include a diode in the circuit to allow current to flow only in one direction, from the solar panel to the battery.

Testing the Current

Sometimes, you may need to test the current for brightness or other power issues with the LED light. Here's a simple method using a low-powered LED in electronic circuits:

Step 1: Prepare the Multimeter

Set the multimeter to measure DC in the range of 200 mA.

Step 2: Connect the Test Lead

Connect the solar panel's red wire to the long LED lead using an alligator clip test lead. Then, connect the multimeter's red probe to the LED's short lead and its black probe to the solar panel's black wire. This will form a series circuit.

Step 3: Test an LED

Position the LED about one foot above the panel and turn it on. The LED should light up. If it doesn't, double-check the wiring and multimeter settings.

Step 4: Check the Current

Read the current on the multimeter to see exactly how much current is passing through the LED. Compare this reading to the LED's specifications to ensure it meets the required current.

>>> See More How does remote control functionality work with yellow LED strip lights at https://www.flickr.com/photos/bestledlightstripsblls/53152738681